When it was first discovered that high-pressure waterjets could significantly improve the performance of mechanical cutting tools, whether in machining metal, or in cutting rock, it was anticipated that this would have a broad-ranging application. This has not been the case, and the reasons are varied, depending on the application, but quite often they relate […]

Tag Archives: Waterjetting

The addition of a high-pressure waterjet to the leading edge of a sharp tool can make a considerable difference to the performance of that tool. I have discussed this a little in two earlier posts, the first of which was an introduction to the topic, and the second highlighted the problems of getting the nozzle […]

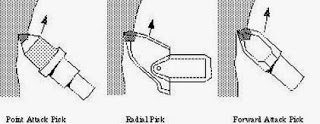

When mankind first began cutting out flints to make the tools and weapons that helped make primitive life more successful they often used either bone antlers or stones from the river as the tool to cut into the chalk or other host rock that held the flint. For thousands of years as rock was excavated […]

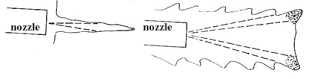

At the end of the last post I mentioned the benefits that could occur if two jets were directed to intersect at a distance from the nozzle. Marian Mazurkiewicz did a lot of early work on this, and it was written up in an ASTM STP.* Because it has a couple of applications that include […]

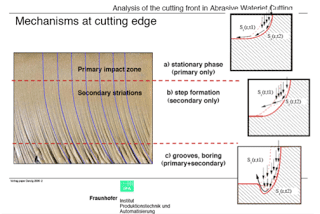

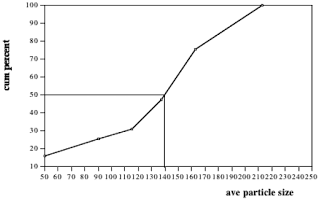

A single waterjet, whether with or without abrasive, will cut a tapering slot as it penetrates into a target material. This is because, as the jet penetrates into the surface, the outer edges of the jet lose their energy in cutting, and the narrower central core remains capable of cutting, on a continually narrowing path, […]

In the last post I wrote about the impact of smaller jet diameters, and higher pressures, in truncating the range over which a waterjet is effective. The same is true, to an extent, when one adds abrasive to the water. Our “green tube” test has been described in earlier posts, where the distance over which […]

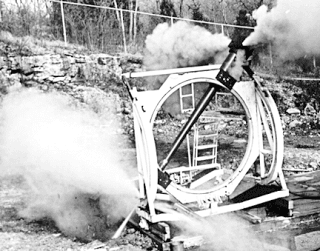

The range over which a waterjet is able to cut material can widely quite significantly, depending on a wide range of factors, including abrasive content. An earlier post described the way in which students in a waterjet class were shown some of the difficulties in assessing risks arising from the use of a waterjet, and […]

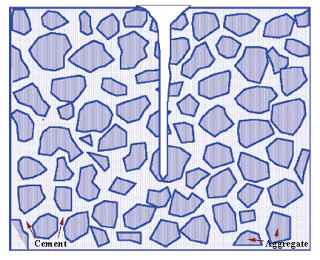

The most popular applications of high-pressure water on concrete deal with the removal of dirt and undesired coatings from the surface, or the removal of layers of the immediate surface for repair, hydro-demolition. There is, however, also an application where the concrete has to be removed in its entirety. Most often, this is done with […]

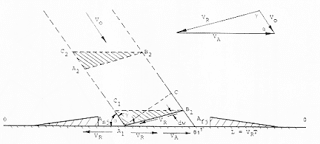

In this short section of the series I have been discussing some of the issues that relate to cutting through concrete. In today’s piece the discussion will continue, focusing on the angles that the jets are set at, when making repeated passes over an area to deepen the cut. The basic premise of the discussion […]

The control of cut depth is one of the more difficult aspects of using high pressure waterjets in places where the aim is not to cut all the way through a part. The ability of an abrasive jet to continue cutting beyond the expected target depth can first be evident to an operator when they […]

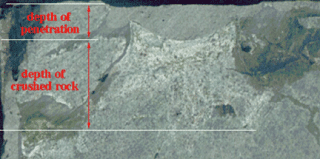

There are a number of differences that take place when high-pressure waterjet operators change from a lower pressure, higher volume flow rate to one where the jets are operated at a higher pressure, with a smaller jet size. One way of illustrating the difference is in the way that the jet will interact with concrete, […]

I began to write these posts on waterjet applications almost two years ago, and it seems appropriate, therefore, to provide an index to those articles, which generally focus on a different topic each month, with four or five sub-topics within that theme. 1. An Introduction to the Topic Background to the series Initial Considerations of […]

In an early section of these notes on high-pressure water and its uses, there was a review of some of the ways in which jet power could be assessed. For the most part the best way to see how changes in a system alter the way the jets cut is to run a simple cutting […]

When the Direct Injection of Abrasive jet (DIAjet) was first introduced to the general public, back in 1986, there was some initial skepticism as to the overall market potential for the system. Certainly, as the next post will discuss, the ability to transfer higher levels of energy from the pressurized water to the entrained abrasive […]

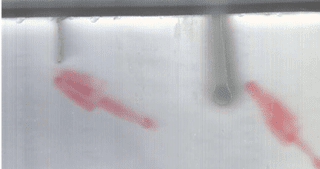

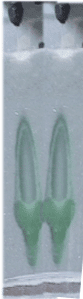

One way to illustrate the benefits of simultaneously cutting adjacent channels through a material is to artificially show how the jets would appear if they were simultaneously cutting through glass beads. An earlier post showed what water penetration around single jet cutting into beads looked like, and if a second image is placed close enough […]