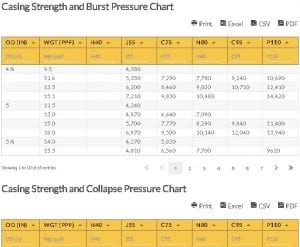

Casing Strength and Burst Pressure Chart

The success of oil production depends on the performance of structures like the line pipe which is a vital component of the process.

In oil production, the line pipe is what functions as a retainer in the well that keeps out fluids and confines oil from the soil to the ground up. Aside from this primary purpose, the line pipe also stabilizes the wellbore. Thus, it must be able to withstand different kinds of pressure from tension loads in its suspension, from fluids surrounding the casing, and from the internal pressure resulting from the oil production itself.

Ultimately, there are a number of factors that can affect how the line pipe can perform, and this is why the casing strength and burst pressure chart becomes a major consideration in purchasing line pipe.

Casing Strength and Burst Pressure Chart

The Casing Strength and Burst Pressure Chart identifies the different pressures that the line pipe has to control during drilling, production, and workover operations. The steel line pipe is being used in the transportation of extracted petroleum resources, because this material is able to handle high pressures and is proven to be durable even after years of operation.

Casing Strength and Burst Pressure Chart

| OD (in) | Wgt (ppf) | H40 | J55 | C75 | N80 | C95 | P110 | |

|---|---|---|---|---|---|---|---|---|

| wdt_ID | OD (in) | Wgt (ppf) | H40 | J55 | C75 | N80 | C95 | P110 |

| 1 | 4 ½ | 9.5 | 4,380 | |||||

| 2 | 11.6 | 5,350 | 7,290 | 7,780 | 9,240 | 10,690 | ||

| 3 | 13.5 | 6,200 | 8,460 | 9,020 | 10,710 | 12,410 | ||

| 4 | 15.1 | 7,210 | 9,830 | 10,480 | 14,420 | |||

| 5 | 5 | 11.5 | 4,240 | |||||

| 6 | 13.0 | 4,870 | 6,640 | 7,090 | ||||

| 7 | 15.0 | 5,700 | 7,770 | 8,290 | 9,840 | 11,400 | ||

| 8 | 18.0 | 6,970 | 9,500 | 10,140 | 12,040 | 13,940 | ||

| 9 | 5 ½ | 14.0 | 4,270 | 5,820 | ||||

| 10 | 15.5 | 4,810 | 6,560 | 7,700 | 9620 |

Casing Strength and Burst Pressure Chart

| OD (in) | Wgt (ppf) | H40 | J55 | C75 | N80 | C95 | P110 | |

|---|---|---|---|---|---|---|---|---|

| wdt_ID | OD (in) | Wgt (ppf) | H40 | J55 | C75 | N80 | C95 | P110 |

| 1 | 4 ½ | 9.5 | 4,380 | |||||

| 2 | 11.6 | 5,350 | 7,290 | 7,780 | 9,240 | 10,690 | ||

| 3 | 13.5 | 6,200 | 8,460 | 9,020 | 10,710 | 12,410 | ||

| 4 | 15.1 | 7,210 | 9,830 | 10,480 | 14,420 | |||

| 5 | 5 | 11.5 | 4,240 | |||||

| 6 | 13.0 | 4,870 | 6,640 | 7,090 | ||||

| 7 | 15.0 | 5,700 | 7,770 | 8,290 | 9,840 | 11,400 | ||

| 8 | 18.0 | 6,970 | 9,500 | 10,140 | 12,040 | 13,940 | ||

| 9 | 5 ½ | 14.0 | 4,270 | 5,820 | ||||

| 10 | 15.5 | 4,810 | 6,560 | 7,700 | 9620 |

Casing Strength and Collapse Pressure Chart

| OD (in) | Wgt (ppf) | H40 | J55 | C75 | N80 | C95 | P110 | |

|---|---|---|---|---|---|---|---|---|

| wdt_ID | OD (in) | Wgt (ppf) | H40 | J55 | C75 | N80 | C95 | P110 |

| 1 | 4 ½ | 9.5 | 3,310 | |||||

| 2 | 11.6 | 4,960 | 6100 | 6,350 | 7,030 | 7,580 | ||

| 3 | 13.5 | 6,420 | 8,140 | 8,540 | 9,660 | 10,680 | ||

| 4 | 15.1 | 7,620 | 10,390 | 11,080 | 14,350 | |||

| 5 | 5 | 11.5 | 3,060 | |||||

| 6 | 13.0 | 4,140 | 4990 | 5140 | ||||

| 7 | 15.0 | 5,500 | 6970 | 7250 | 8090 | 8830 | ||

| 8 | 18.0 | 7,390 | 10,000 | 10490 | 12010 | 13470 | ||

| 9 | 5 ½ | 14.0 | 3120 | 3560 | ||||

| 10 | 15.5 | 3860 | 4860 | 4990 | 5620 |

Casing Strength and Collapse Pressure Chart

| OD (in) | Wgt (ppf) | H40 | J55 | C75 | N80 | C95 | P110 | |

|---|---|---|---|---|---|---|---|---|

| wdt_ID | OD (in) | Wgt (ppf) | H40 | J55 | C75 | N80 | C95 | P110 |

| 1 | 4 ½ | 9.5 | 3,310 | |||||

| 2 | 11.6 | 4,960 | 6100 | 6,350 | 7,030 | 7,580 | ||

| 3 | 13.5 | 6,420 | 8,140 | 8,540 | 9,660 | 10,680 | ||

| 4 | 15.1 | 7,620 | 10,390 | 11,080 | 14,350 | |||

| 5 | 5 | 11.5 | 3,060 | |||||

| 6 | 13.0 | 4,140 | 4990 | 5140 | ||||

| 7 | 15.0 | 5,500 | 6970 | 7250 | 8090 | 8830 | ||

| 8 | 18.0 | 7,390 | 10,000 | 10490 | 12010 | 13470 | ||

| 9 | 5 ½ | 14.0 | 3120 | 3560 | ||||

| 10 | 15.5 | 3860 | 4860 | 4990 | 5620 |

In the Casing Strength and Burst Pressure Chart above, the first key term is the casing outer diameter which is basically the specification of the pipe that goes into the hole.

Next is the weight of the line pipe which is measured in pound per feet. On the other half of the table, burst pressure and collapse pressure are identified for each type of line pipe.

Burst pressure is the internal pressure that the tubing as a whole can endure, while collapse pressure is the pressure at which the same casing will “collapse” as a result of difference between the external and internal pressures. This happens as a result of numerous situations including trapped pressure in the line pipe.

In simpler words, their difference is that collapse pressure is the maximum pressure outside the pipe that will lead to its damage while burst pressure is the maximum pressure inside the pipe that will lead to its damage. These key terms make up the casing strength. The burst pressure chart is important in dealing with oil production’s constant involvement in high pressures.

Casing Strength and Burst Pressure Chart Abbreviations:

- OD – Outside Diameter

- in – inches

- ppf – pound per feet

- psi – pounds per square inch

- Wgt – weight

Go here if you are looking for the Casing Dimensions and Bit Clearance Chart.