Casing Size and Grade Chart

Oil and gas production begins by drilling a well in an oilfield. Once a borehole is made, structural stability should be retained. To do this, a casing is inserted and pushed inside so that the wellstream will be sufficiently supported and protected and will not collapse or cave in. The gap between the wall of the well and the casing is cemented to fix the casing in place.

Casing sizes are of different diameters and wall thickness. Made according to various specifications set by international organizations such as the American Petroleum Institute (API) and the International Organization for Standardization (ISO), the casing size nominal diameter is equivalent to the theoretical diameter of the pipe and allowing for tolerance usually for an oversized pipe.

Casing grades are based on set standards, or upon request, may be custom-made by particular manufacturers according to specifications provided by the customers.

Casing Size Importance

The inside diameter of the casing is vital as this dimension is a primary consideration in determining the tools that can pass through it. Likewise, it either determines the wall thickness or vice versa where the diameter is dependent on the required wall thickness.

Casing Grades Classification

Casing grades are classified according to metallurgical properties and mechanical properties such as yield strength, tensile strength, and hardness. Manufacturers adhering to standards produce casing grades that meet ISO 11960 or API Spec 5CT. These include yield strengths that range from 40,000 psi to 125,000 psi. As the grade increases, so does the strength of casing material.

Casing grades that do not conform to specifications are special grades that require certain variations like resistance to sulfide stress cracking, high tensile strength, or high collapse strength.

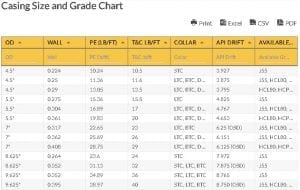

Casing Size and Grade Chart

| OD | Wall | PE (lb/ft) | T&C lb/ft | Collar | API Drift | Available Grades | |

|---|---|---|---|---|---|---|---|

| wdt_ID | OD | Wall | PE (lb/ft) | T&C lb/ft | Collar | API Drift | Available Grades |

| 1 | 4.5″ | 0.224 | 10.24 | 10.5 | STC | 3.927 | J55 |

| 2 | 4.5″ | 0.25 | 11.36 | 11.6 | LTC, BTC, DWC & Premium | 3.875 | J55, HCL80, HCP110 |

| 3 | 4.5″ | 0.29 | 13.05 | 13.5 | LTC, BTC, DWC & Premium | 3.795 | HCL80, HCP110 |

| 4 | 5.5″ | 0.275 | 15.36 | 15.5 | LTC | 4.825 | J55 |

| 5 | 5.5″ | 0.304 | 16.89 | 17 | LTC, BTC, DWC & Premium | 4.767 | J55, HCL80, HCP110 |

| 6 | 5.5″ | 0.361 | 19.83 | 20 | LTC, BTC, DWC & Premium | 4.653 | HCL80, HCP110 |

| 7 | 7″ | 0.317 | 22.65 | 23 | LTC, BTC | 6.25 (OSD) | J55, HCL80, HCP110 |

| 8 | 7″ | 0.362 | 25.69 | 26 | LTC, BTC, DWC & Premium | 6.151 | J55, HCL80, HCP110 |

| 9 | 7″ | 0.408 | 28.75 | 29 | LTC, BTC, DWC & Premium | 6.125 (OSD) | HCL80, HCP110 |

| 10 | 8.625″ | 0.264 | 23.6 | 24 | STC | 7.972 | J55 |

| 11 | 8.625″ | 0.352 | 31.13 | 32 | STC, LTC, BTC | 7.875 (OSD) | J55 |

| 12 | 9.625″ | 0.352 | 34.89 | 36 | STC, LTC, BTC | 8.765 | J55 |

| 13 | 9.625″ | 0.395 | 38.97 | 40 | STC, LTC, BTC | 8.750 (OSD) | J55, HCL80, HCK55 |

| 14 | 9.625″ | 0.435 | 43.5 | 40 | LTC, BTC, DWC | 8.750 (OSD) | HCL80, HCP110 |

| 15 | 10.75″ | 0.35 | 38.91 | 40.5 | STC, BTC | 9.894 | J55 |

| 16 | 10.75″ | 0.4 | 44.26 | 45.5 | STC, LTC, BTC | 9.875 (OSD) | J55 |

| 17 | 13.375″ | 0.33 | 46.02 | 48 | STC | 12.559 | J55 |

| 18 | 13.375″ | 0.38 | 52.79 | 54.5 | STC, LTC, BTC | 12.459 | J55 |

| 19 | 13.375″ | 0.43 | 59.5 | 61 | STC, LTC, BTC | 12.359 | J55 |

| 20 | 13.375″ | 0.48 | 66.17 | 68 | STC, LTC, BTC | 12.259 | J55 |

Casing Size and Grade Chart

| OD | Wall | PE (lb/ft) | T&C lb/ft | Collar | API Drift | Available Grades | |

|---|---|---|---|---|---|---|---|

| wdt_ID | OD | Wall | PE (lb/ft) | T&C lb/ft | Collar | API Drift | Available Grades |

| 1 | 4.5″ | 0.224 | 10.24 | 10.5 | STC | 3.927 | J55 |

| 2 | 4.5″ | 0.25 | 11.36 | 11.6 | LTC, BTC, DWC & Premium | 3.875 | J55, HCL80, HCP110 |

| 3 | 4.5″ | 0.29 | 13.05 | 13.5 | LTC, BTC, DWC & Premium | 3.795 | HCL80, HCP110 |

| 4 | 5.5″ | 0.275 | 15.36 | 15.5 | LTC | 4.825 | J55 |

| 5 | 5.5″ | 0.304 | 16.89 | 17 | LTC, BTC, DWC & Premium | 4.767 | J55, HCL80, HCP110 |

| 6 | 5.5″ | 0.361 | 19.83 | 20 | LTC, BTC, DWC & Premium | 4.653 | HCL80, HCP110 |

| 7 | 7″ | 0.317 | 22.65 | 23 | LTC, BTC | 6.25 (OSD) | J55, HCL80, HCP110 |

| 8 | 7″ | 0.362 | 25.69 | 26 | LTC, BTC, DWC & Premium | 6.151 | J55, HCL80, HCP110 |

| 9 | 7″ | 0.408 | 28.75 | 29 | LTC, BTC, DWC & Premium | 6.125 (OSD) | HCL80, HCP110 |

| 10 | 8.625″ | 0.264 | 23.6 | 24 | STC | 7.972 | J55 |

| 11 | 8.625″ | 0.352 | 31.13 | 32 | STC, LTC, BTC | 7.875 (OSD) | J55 |

| 12 | 9.625″ | 0.352 | 34.89 | 36 | STC, LTC, BTC | 8.765 | J55 |

| 13 | 9.625″ | 0.395 | 38.97 | 40 | STC, LTC, BTC | 8.750 (OSD) | J55, HCL80, HCK55 |

| 14 | 9.625″ | 0.435 | 43.5 | 40 | LTC, BTC, DWC | 8.750 (OSD) | HCL80, HCP110 |

| 15 | 10.75″ | 0.35 | 38.91 | 40.5 | STC, BTC | 9.894 | J55 |

| 16 | 10.75″ | 0.4 | 44.26 | 45.5 | STC, LTC, BTC | 9.875 (OSD) | J55 |

| 17 | 13.375″ | 0.33 | 46.02 | 48 | STC | 12.559 | J55 |

| 18 | 13.375″ | 0.38 | 52.79 | 54.5 | STC, LTC, BTC | 12.459 | J55 |

| 19 | 13.375″ | 0.43 | 59.5 | 61 | STC, LTC, BTC | 12.359 | J55 |

| 20 | 13.375″ | 0.48 | 66.17 | 68 | STC, LTC, BTC | 12.259 | J55 |

The Casing Size and Grade Chart shows the following fields:

The Outside Diameter (OD) is within ± 0.75% of the tolerance and must not be undersized.

The Inside Diameter (ID) is designated as a drift diameter with a wall thickness equivalent to 87.5% of the nominal wall thickness and a tolerance of -12.5%.

The Drift Diameter must pass through the casing within reasonable force exerted to the mandrel’s weight.

Plain Ends (PE) refer to the threaded portion of the casing pipe without the coupling

Threaded and Coupled (T&C) ends refer to the threaded and coupled portion of the casing

Collar or coupling refers to joints of casing and enables the casing string to run.

Grades classifications refer to (letter) chemical composition and (number) minimum yield strength.

Casing Size and Grade Chart Abbreviations:

- OD – Outside Diameter

- PE # / ft – Plain Ends number per feet

- T&C # / ft – Threaded and Coupled Ends number per feet

- STC – Short Thread and Coupled

- LTC – Long Thread and Coupled

- BTC – Buttress Thread Connection

- DWC – Drill With Casing

- API – American Petroleum Institute

Go here if you are looking for the Casing Strength and Burst Pressure Chart.