Tubing Nipple Chart

Tubing nipples, in general, are used for plumbing or piping purposes.

A nipple is a piece of pipe threaded at both ends with male threads. The tubing nipple also means a completion part that is fabricated and with a machined internal surface. An example is a landing nipple that is used in downhole completion or the process of preparing the hole bottom for injection or production in the oil industry.

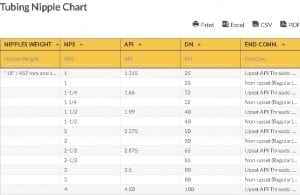

Tubing Nipple Chart

The Tubing Nipple Chart shows the different data for tubing nipples such as the standard weight, size, and end connection. The table for tubing nipple can help determine the correct size, length, shape, and type of the tubing’s end connection. The tubing nipple table shows different sizes for 18 in and 457 mm (and shorter) tubing (upset and non-upset) with their corresponding metric standards such as NPS, API, and DN. The top heading of the table also shows nominal sizes, lengths, tubing API threads, grades, wall thicknesses, and various material grades such as brass or stainless.

| wdt_ID | Weight | NPS | API | ND | End Conn. |

|---|---|---|---|---|---|

| 1 | 18” / 457 mm and shorter EUE and NUE - SW | 1 | 1.315 | 25 | EUE API Threads: One or Both Ends |

| 2 | 1 | 25 | NUE (Regular) | ||

| 3 | 1-1/4 | 1.66 | 32 | EUE API Threads: One or Both Ends | |

| 4 | 1 1/4 | 32 | NUE (Regular) | ||

| 5 | 1-1/2 | 1.99 | 40 | EUE API Threads: One or Both Ends | |

| 6 | 1-1/2 | 40 | NUE (Regular) | ||

| 7 | 2 | 2.375 | 50 | EUE API Threads: One or Both Ends | |

| 8 | 2 | 50 | NUE (Regular) | ||

| 9 | 2-1/2 | 2.875 | 65 | EUE API Threads: One or Both Ends | |

| 10 | 2-1/2 | 65 | NUE (Regular) | ||

| 11 | 3 | 3.5 | 80 | EUE API Threads: One or Both Ends | |

| 12 | 3 | 80 | NUE (Regular) | ||

| 13 | 4 | 4.50 | 100 | EUE API Threads: One or Both Ends | |

| 14 | 4 | 100 | NUE (Regular) | ||

| 15 | 18” / 457 mm and shorter EUE and NUE - XHW | 1 | 1.315 | 25 | EUE API Threads: One or Both Ends |

| 16 | 1 | 25 | NUE(Regular) | ||

| 17 | 1-1/4 | 1.66 | 32 | EUE API Threads: One or Both Ends | |

| 18 | 1 1/4 | 32 | NUE(Regular) | ||

| 19 | 1-1/2 | 1.99 | 40 | EUE API Threads: One or Both Ends | |

| 20 | 1-1/2 | 40 | NUE(Regular) | ||

| 21 | 2 | 2.375 | 50 | EUE API Threads: One or Both Ends | |

| 22 | 2 | 50 | NUE(Regular) | ||

| 23 | 2-1/2 | 2.875 | 65 | EUE API Threads: One or Both Ends | |

| 24 | 2-1/2 | 65 | NUE(Regular) | ||

| 25 | 3 | 3.5 | 80 | EUE API Threads: One or Both Ends | |

| 26 | 3 | 80 | NUE(Regular) | ||

| 27 | 4 | 4.50 | 100 | EUE API Threads: One or Both Ends | |

| 28 | 4 | 100 | NUE(Regular) |

| wdt_ID | Weight | NPS | API | ND | End Conn. |

|---|---|---|---|---|---|

| 1 | 18” / 457 mm and shorter EUE and NUE - SW | 1 | 1.315 | 25 | EUE API Threads: One or Both Ends |

| 2 | 1 | 25 | NUE (Regular) | ||

| 3 | 1-1/4 | 1.66 | 32 | EUE API Threads: One or Both Ends | |

| 4 | 1 1/4 | 32 | NUE (Regular) | ||

| 5 | 1-1/2 | 1.99 | 40 | EUE API Threads: One or Both Ends | |

| 6 | 1-1/2 | 40 | NUE (Regular) | ||

| 7 | 2 | 2.375 | 50 | EUE API Threads: One or Both Ends | |

| 8 | 2 | 50 | NUE (Regular) | ||

| 9 | 2-1/2 | 2.875 | 65 | EUE API Threads: One or Both Ends | |

| 10 | 2-1/2 | 65 | NUE (Regular) | ||

| 11 | 3 | 3.5 | 80 | EUE API Threads: One or Both Ends | |

| 12 | 3 | 80 | NUE (Regular) | ||

| 13 | 4 | 4.50 | 100 | EUE API Threads: One or Both Ends | |

| 14 | 4 | 100 | NUE (Regular) | ||

| 15 | 18” / 457 mm and shorter EUE and NUE - XHW | 1 | 1.315 | 25 | EUE API Threads: One or Both Ends |

| 16 | 1 | 25 | NUE(Regular) | ||

| 17 | 1-1/4 | 1.66 | 32 | EUE API Threads: One or Both Ends | |

| 18 | 1 1/4 | 32 | NUE(Regular) | ||

| 19 | 1-1/2 | 1.99 | 40 | EUE API Threads: One or Both Ends | |

| 20 | 1-1/2 | 40 | NUE(Regular) | ||

| 21 | 2 | 2.375 | 50 | EUE API Threads: One or Both Ends | |

| 22 | 2 | 50 | NUE(Regular) | ||

| 23 | 2-1/2 | 2.875 | 65 | EUE API Threads: One or Both Ends | |

| 24 | 2-1/2 | 65 | NUE(Regular) | ||

| 25 | 3 | 3.5 | 80 | EUE API Threads: One or Both Ends | |

| 26 | 3 | 80 | NUE(Regular) | ||

| 27 | 4 | 4.50 | 100 | EUE API Threads: One or Both Ends | |

| 28 | 4 | 100 | NUE(Regular) |

Tubing Nipple Chart Abbreviations:

- N.P.S. – Nominal Pipe Size

- A.P.I. – American Petroleum Institute

- N.D. – Nominal Diameter

Understanding the Terms in the Tubing Nipple Table

End Connection specs – This column shows whether the drill pipe’s or tube’s threaded end connection is upset or non-upset and if the pipe is threaded at both ends.

Non-upset (NUE) tubing – Refers to the end of the pipe without the straight thread and extra thick collar. The NUE costs less slightly than the EUE and features less joint strength. Likewise, the NUE doesn’t undergo the upsetting (forging) process. The NUE and the EUE differ in their outer or inner diameters.

Upset tubing or EUE – Features a long tube with the joint to ease the extraction of gas and oil. Tubing joints act as a conduit in well operations and measure up to 30 feet or 9 meters. Drill pipe is used in drilling natural gas below 5,000 feet with a mud rotary. An upset drill pipe can provide a stronger and thicker drill area. Upsetting can be made in the pipe interior or exterior.

Size of Tubing Nipples

The table specifies three standard and metric designations or sizes:

- Nominal Pipe Size (NPS) ranges from 1 to 4

- The American Petroleum Institute’s sizes range from 1.315 to 4.50, except for the non-upset pipe end connection

- Diameter Nominal (DN) conforms to the International Standards Organization or ISO. Its sizes range from 25 to 100.

Tubing nipples are classified into those that have the standard weight and those with extra heavy weight. Both are 18 in or 457 mm (and shorter) upset and non-upset.

Procuring Tubing Nipples for Completion and Workover Operations

Selecting the correct tubing nipple specifications ensures proper fit-up with downhole completion equipment, landing nipples, flow control devices, and surface connections throughout the production life of oil and gas wells. The charts above provide comprehensive dimensional and material specifications for API tubing nipples in both upset (EUE) and non-upset (NUE) configurations, enabling completion engineers and field personnel to match nipple specifications to specific wellbore requirements and equipment compatibility needs. Tubing nipples serve critical functions in completion assemblies, including connections between tubing joints, transitions between different tubing sizes or grades, and interface points for subsurface safety valves, gas lift mandrels, and other downhole equipment. Understanding the relationship between nipple dimensions, thread specifications, wall thickness, and material grades ensures reliable connections that maintain pressure integrity under production conditions while providing compatibility with wireline tools, coiled tubing interventions, and workover equipment used throughout the well’s operational life.

Flowtech Energy maintains inventory of API-certified tubing nipples in standard sizes from 1-inch through 4-inch nominal pipe size, available in both standard weight and extra heavy configurations to match various pressure ratings and application requirements. Our tubing nipple inventory includes carbon steel grades for conventional applications, corrosion-resistant materials for sour service environments, and specialty alloys including stainless steel and brass for specific chemical compatibility needs. We supply nipples with complete material certifications documenting thread specifications, dimensional accuracy, and metallurgical properties required for API compliance and operator quality standards. Whether you’re assembling completion strings for new wells, performing tubing repairs during workovers, or maintaining inventory for field operations and emergency repairs, our technical team can assist with specification verification, material selection for corrosive environments, and coordination of delivery to support your operational schedule. If you need assistance selecting appropriate tubing nipple specifications for your completion design, sourcing certified materials with complete documentation and traceability, or coordinating supply for field operations and maintenance activities, contact Flowtech Energy at 1-877-645-6693. We deliver reliable supply chain support for completion components and downhole equipment—ensuring your operations have the right materials to maintain well integrity, production performance, and operational flexibility throughout the productive life of your assets.

Go here if you are looking for the Tubing Torque for Long-Thread Chart.