Drill Rod Thread Compatibility Chart

Drill rod thread basically differs for every type of drill rod. Threads of standard drill rods come in aluminum or mid-weight steel, allowing ergonomic flexibility that provides better handling capacities even on most demanding applications. Other conditions, including mineral explorations, require rod threads that can be used with standard core barrels, just like the WJ type threads. Drill rod thread undergoes evaluation during drill rod production and drill rod couplings to ensure that high-quality steel is used and that it can hold up against drilling under the most severe environments.

Drill Rod Thread Types

Parallel Threaded Rods

These rods have female threads at both ends of the steel tube, which can be replaced with pin-to-pin couplers. High-quality seamless carbon steel is used to produce these rods, ensuring sturdiness and uniformity. On the other hand, heat treated-alloy steel is utilized to manufacture male-threaded couplings, delivering maximum durability and wear endurance. Rotary drilling operations can best benefit from these rods.

Taper Threaded Rods

Both replaceable male and female tool joints are available with these drill rods; these are bolted into the rod tube. Heat-treated alloy steel is used to produce these rods to ensure utmost durability and wear resistance.

Drill Rod Thread Common Problems

Regular inspection of all machineries is implemented within the rig, looking for possible issues that can occur, such as:

- Thread Galling – Drilling rod threads may encounter galling when subjected to high torque operations or loading without proper lubrication.

- Cracked Drill Rod Threads – Drill rod thread cracks are due to extreme vibration and over torqueing.

- Thread Belling – This can be caused by the same factors in thread galling, accompanied by thinning or wearing out of the drill rod threads.

- Drill Rod Thread Leak – Leak can be due to cracks, wearing out, or damage of the drill rod threads.

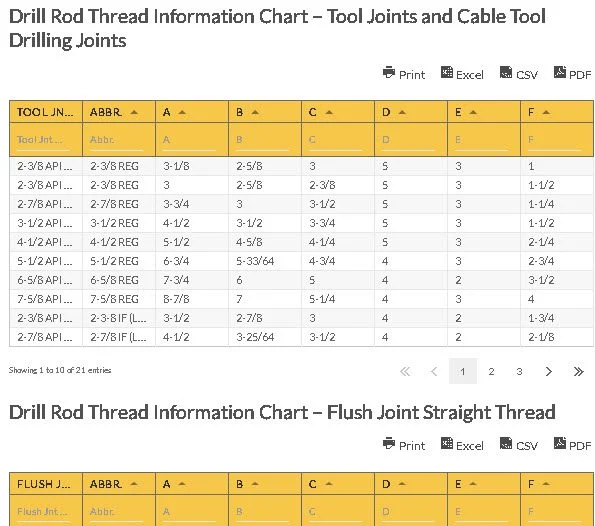

Drill Rod Thread Information Chart – Tool Joints and Cable Tool Drilling Joints

| wdt_ID | Tool Jnt Name | Abbr. | A | B | C | D | E | F |

|---|---|---|---|---|---|---|---|---|

| 1 | 2-3/8 API REGULAR | 2-3/8 REG | 3-1/8 | 2-5/8 | 3 | 5 | 3 | 1 |

| 2 | 2-3/8 API REGULAR (DSI MOD) | 2-3/8 REG | 3 | 2-5/8 | 2-3/8 | 5 | 3 | 1-1/2 |

| 3 | 2-7/8 API REGULAR | 2-7/8 REG | 3-3/4 | 3 | 3-1/2 | 5 | 3 | 1-1/4 |

| 4 | 3-1/2 API REGULAR | 3-1/2 REG | 4-1/2 | 3-1/2 | 3-3/4 | 5 | 3 | 1-1/2 |

| 5 | 4-1/2 API REGULAR | 4-1/2 REG | 5-1/2 | 4-5/8 | 4-1/4 | 5 | 3 | 2-1/4 |

| 6 | 5-1/2 API REGULAR | 5-1/2 REG | 6-3/4 | 5-33/64 | 4-3/4 | 4 | 3 | 2-3/4 |

| 7 | 6-5/8 API REGULAR | 6-5/8 REG | 7-3/4 | 6 | 5 | 4 | 2 | 3-1/2 |

| 8 | 7-5/8 API REGULAR | 7-5/8 REG | 8-7/8 | 7 | 5-1/4 | 4 | 3 | 4 |

| 9 | 2-3/8 API INTERNAL FLUSH LH, RH | 2-3-8 IF (LH OR RH) | 3-1/2 | 2-7/8 | 3 | 4 | 2 | 1-3/4 |

| 10 | 2-7/8 API INTERNAL FLUSH LH. RH | 2-7/8 IF (LH OR RH) | 4-1/2 | 3-25/64 | 3-1/2 | 4 | 2 | 2-1/8 |

| 11 | 3-1/2 API INTERNAL FLUSH LH. RH | 3-1/2 IF (LH OR RH) | 4-3/4 | 4-1/64 | 4 | 4 | 2 | 2-11/16 |

| 12 | 4 API INTERNAL FLUSH | 4 IF | 5-3/4 | 4-53/64 | 4-1/2 | 4 | 2 | 3-1/4 |

| 13 | 4-1/2 API INTERNAL FLUSH | 4-1/2 IF | 6-1/8 | 5-1/4 | 4-1/2 | 4 | 2 | 3-3/4 |

| 14 | 2-3/8 MAYHEW JUNIOR | MAYHEW JUNIOR | 2-3/4 | 2-21/64 | 2-1/4 | 4 | 2 | 1-1/2 |

| 15 | 2-3/8 MAYHEW REGULAR | MAYHEW REGULAR | 3-1/4 | 2-35/64 | 3 | 4 | 1-1/2 | 1-5/8 |

| 16 | 2-3/8 JOY FULL HOLE | 3/8 JOY FH | 3-1/8 | 2-35/64 | 3 | 4 | 1-1/2 | 1-5/8 |

| 17 | 2-3/8 FAILING EXPLORATION | 2-3/8 FEDP | 2-31/32 | 2-1/2 | 2-3/4 | 4 | 2 | 1-1/2 |

| 18 | 2-7/8 FAILING EXPLORATION | 2-7/8 FEDP | 3-3/4 | 3-1/8 | 3-1/4 | 4 | 2 | 1-7/8 |

| 19 | 3-1/2 API FULL HOLE | 3-1/2 FH | 4-5/8 | 4 | 3-3/4 | 5 | 3 | 2-1/8 |

| 20 | 4 API FULL HOLE | 4FH | 5-1/4 | 4-9/32 | 4-1/2 | 4 | 2 | 2-13/16 |

| 21 | 4-1/2 API FULL HOLE | 4-1/2 FH | 5-3/4 | 4-51/64 | 4 | 5 | 3 | 3 |

Drill Rod Thread Information Chart – Tool Joints and Cable Tool Drilling Joints

| wdt_ID | Tool Jnt Name | Abbr. | A | B | C | D | E | F |

|---|---|---|---|---|---|---|---|---|

| 1 | 2-3/8 API REGULAR | 2-3/8 REG | 3-1/8 | 2-5/8 | 3 | 5 | 3 | 1 |

| 2 | 2-3/8 API REGULAR (DSI MOD) | 2-3/8 REG | 3 | 2-5/8 | 2-3/8 | 5 | 3 | 1-1/2 |

| 3 | 2-7/8 API REGULAR | 2-7/8 REG | 3-3/4 | 3 | 3-1/2 | 5 | 3 | 1-1/4 |

| 4 | 3-1/2 API REGULAR | 3-1/2 REG | 4-1/2 | 3-1/2 | 3-3/4 | 5 | 3 | 1-1/2 |

| 5 | 4-1/2 API REGULAR | 4-1/2 REG | 5-1/2 | 4-5/8 | 4-1/4 | 5 | 3 | 2-1/4 |

| 6 | 5-1/2 API REGULAR | 5-1/2 REG | 6-3/4 | 5-33/64 | 4-3/4 | 4 | 3 | 2-3/4 |

| 7 | 6-5/8 API REGULAR | 6-5/8 REG | 7-3/4 | 6 | 5 | 4 | 2 | 3-1/2 |

| 8 | 7-5/8 API REGULAR | 7-5/8 REG | 8-7/8 | 7 | 5-1/4 | 4 | 3 | 4 |

| 9 | 2-3/8 API INTERNAL FLUSH LH, RH | 2-3-8 IF (LH OR RH) | 3-1/2 | 2-7/8 | 3 | 4 | 2 | 1-3/4 |

| 10 | 2-7/8 API INTERNAL FLUSH LH. RH | 2-7/8 IF (LH OR RH) | 4-1/2 | 3-25/64 | 3-1/2 | 4 | 2 | 2-1/8 |

| 11 | 3-1/2 API INTERNAL FLUSH LH. RH | 3-1/2 IF (LH OR RH) | 4-3/4 | 4-1/64 | 4 | 4 | 2 | 2-11/16 |

| 12 | 4 API INTERNAL FLUSH | 4 IF | 5-3/4 | 4-53/64 | 4-1/2 | 4 | 2 | 3-1/4 |

| 13 | 4-1/2 API INTERNAL FLUSH | 4-1/2 IF | 6-1/8 | 5-1/4 | 4-1/2 | 4 | 2 | 3-3/4 |

| 14 | 2-3/8 MAYHEW JUNIOR | MAYHEW JUNIOR | 2-3/4 | 2-21/64 | 2-1/4 | 4 | 2 | 1-1/2 |

| 15 | 2-3/8 MAYHEW REGULAR | MAYHEW REGULAR | 3-1/4 | 2-35/64 | 3 | 4 | 1-1/2 | 1-5/8 |

| 16 | 2-3/8 JOY FULL HOLE | 3/8 JOY FH | 3-1/8 | 2-35/64 | 3 | 4 | 1-1/2 | 1-5/8 |

| 17 | 2-3/8 FAILING EXPLORATION | 2-3/8 FEDP | 2-31/32 | 2-1/2 | 2-3/4 | 4 | 2 | 1-1/2 |

| 18 | 2-7/8 FAILING EXPLORATION | 2-7/8 FEDP | 3-3/4 | 3-1/8 | 3-1/4 | 4 | 2 | 1-7/8 |

| 19 | 3-1/2 API FULL HOLE | 3-1/2 FH | 4-5/8 | 4 | 3-3/4 | 5 | 3 | 2-1/8 |

| 20 | 4 API FULL HOLE | 4FH | 5-1/4 | 4-9/32 | 4-1/2 | 4 | 2 | 2-13/16 |

| 21 | 4-1/2 API FULL HOLE | 4-1/2 FH | 5-3/4 | 4-51/64 | 4 | 5 | 3 | 3 |

Drill Rod Thread Information Chart – Flush Joint Straight Thread

| wdt_ID | Flush Jnt Straight Thread | Abbr. | A | B | C | D | E | F |

|---|---|---|---|---|---|---|---|---|

| 1 | M-50 | M-50 | 2 | 1-3/4 | 1-5/16 | 4 | NO | 1-3/16 |

| 2 | E-ROD | E-ROD | 1-5/16 | 1 | 1-1/2 | 3 | NO | 7/16 |

| 3 | EW - ROD | EW - ROD | 1-3/8 | 1-1/16 | 1-9/16 | 3 | NO | 7/16 |

| 4 | A-ROD | A-ROD | 1-5/8 | 1-17/64 | 1-3/4 | 3 | NO | 9/16 |

| 5 | AW - ROD | AW - ROD | 1-3/4 | 1-3/8 | 1-3/4 | 3 | NO | 5/8 |

| 6 | B-ROD | B-ROD | 1-29/32 | 1-13/32 | 1-7/8 | 3 | NO | 5/8 |

| 7 | BW - ROD | BW - ROD | 2-1/8 | 1-11/16 | 2-1/4 | 3 | NO | 3/4 |

| 8 | N-ROD | 4 THREAD N - ROD | 2-1/8 | 1-7/8 | 2-3/8 | 4 | NO | 1 |

| 9 | N - ROD FAILING TYPE | 3 THREAD N-ROD | 2-3/8 | 1-7/8 | 2-3/4 | 3 | NO | 1-1/8 |

| 10 | NW - ROD | NW - ROD | 2-5/8 | 2-7/32 | 2-3/4 | 3 | NO | 1 -3/8 |

Drill Rod Thread Information Chart – Flush Joint Straight Thread

| wdt_ID | Flush Jnt Straight Thread | Abbr. | A | B | C | D | E | F |

|---|---|---|---|---|---|---|---|---|

| 1 | M-50 | M-50 | 2 | 1-3/4 | 1-5/16 | 4 | NO | 1-3/16 |

| 2 | E-ROD | E-ROD | 1-5/16 | 1 | 1-1/2 | 3 | NO | 7/16 |

| 3 | EW - ROD | EW - ROD | 1-3/8 | 1-1/16 | 1-9/16 | 3 | NO | 7/16 |

| 4 | A-ROD | A-ROD | 1-5/8 | 1-17/64 | 1-3/4 | 3 | NO | 9/16 |

| 5 | AW - ROD | AW - ROD | 1-3/4 | 1-3/8 | 1-3/4 | 3 | NO | 5/8 |

| 6 | B-ROD | B-ROD | 1-29/32 | 1-13/32 | 1-7/8 | 3 | NO | 5/8 |

| 7 | BW - ROD | BW - ROD | 2-1/8 | 1-11/16 | 2-1/4 | 3 | NO | 3/4 |

| 8 | N-ROD | 4 THREAD N - ROD | 2-1/8 | 1-7/8 | 2-3/8 | 4 | NO | 1 |

| 9 | N - ROD FAILING TYPE | 3 THREAD N-ROD | 2-3/8 | 1-7/8 | 2-3/4 | 3 | NO | 1-1/8 |

| 10 | NW - ROD | NW - ROD | 2-5/8 | 2-7/32 | 2-3/4 | 3 | NO | 1 -3/8 |

Drill rod thread comes in various forms and sizes, where some are categorized under the American Petroleum Institute (API) connections and others as premium connections.

API Connections

Single shoulder connections are possible with these, where there is only one torque shoulder on both box and pin. These can be identified as:

- Regular

- Internal Flush (IF)

- Full Hole (FH)

- Numeric Connection (NC)

Premium Connections

Premium connections generally have a double shoulder. They possess an extra torque shoulder at the end of the box, and in the nose of the pin. They can handle higher torque applications and are available in various shapes and sizes:

- Grant Prideco (XT)

- Tenaris (DSTJ)

- Vam (Vam Eis)

- DP Master (MT)

Drill Rod Thread Compatibility Chart Abbreviations:

- A – Outside Diameter

- B – Major Thread Diameter

- C – Length of Pin

- D – Threads per inch

- E – Taper per Foot

- F – Tool Joint Bore

Ensuring Proper Thread Compatibility for Drill Rod Assemblies

Understanding drill rod thread compatibility is critical for preventing connection failures, minimizing non-productive time, and ensuring safe drilling operations across mineral exploration, geotechnical drilling, and water well applications. The charts above provide detailed thread specifications including outside diameter, major thread diameter, pin length, threads per inch, taper per foot, and tool joint bore dimensions that enable drilling contractors and equipment managers to verify compatibility between drill rods, couplings, and downhole tools from different manufacturers. Thread incompatibility can result in costly consequences including cross-threading damage, premature connection wear, thread galling, and catastrophic failures that lead to stuck pipe incidents and lost equipment downhole. Whether you’re working with parallel threaded rods that use pin-to-pin couplers or taper threaded rods with replaceable tool joints, accurate thread specification data ensures proper makeup, adequate torque transfer, and reliable connections throughout demanding drilling operations in hard rock formations, deep boreholes, and challenging ground conditions.

Flowtech Energy supplies drill rods with API-certified thread connections and premium thread designs compatible with major drilling equipment manufacturers and industry-standard core barrel systems. Our inventory includes both parallel and taper threaded drill rods manufactured from high-quality seamless carbon steel tubes with heat-treated alloy steel couplings and tool joints engineered for maximum durability and wear resistance. We provide detailed thread specification documentation to ensure compatibility with your existing drill string components, core barrels, and downhole tooling, eliminating the guesswork and risk associated with mixing incompatible thread types. Our technical team understands that thread integrity directly impacts drilling productivity and equipment longevity, and we can assist with thread inspection procedures, proper makeup techniques, lubrication recommendations, and torque specifications to prevent common thread problems including galling, cracking, belling, and leakage. Whether you’re assembling new drill strings for mineral exploration projects, replacing worn drill rods in active drilling operations, or maintaining equipment inventory for geotechnical and environmental drilling contractors, we deliver expert guidance on thread compatibility, material selection, and procurement strategies that optimize drilling performance and equipment reliability. If you need assistance verifying thread compatibility between drill rod components, sourcing certified drill rods with specific thread configurations, or coordinating delivery and technical support for drilling operations, contact Flowtech Energy at 1-877-645-6693. We provide comprehensive drill rod procurement solutions with complete thread specification documentation—ensuring your drilling operations have compatible, reliable equipment that delivers consistent performance and minimizes costly connection failures in demanding drilling environments.

Go here if you are looking for the Drill Pipe Heavy Weight Chart.