Drill Pipe Specification with Upset and Tool Joint Chart

The drill pipe with upset is manufactured through a forging process where the tube ends are made with thicker walls. The process starts by heating the ends of the tube, followed by pressure application utilizing a closed die hydraulic forging press, which will create the upsets.

An external upset part with an outer taper is formed on one end of the steel tube through upsetting and pressing. Internal upset forging may then be initiated by displacing the outer taper to an internal upset part with an internal taper. This is done by pressing the external upset portion. An internal upset die can deliver the final part of the internal upset forging process.

Not all drill pipes are upset. This is secondary to the expenses required to successfully produce drill pipe with upset.

The Tool joints of the drill pipe are the enlarged and threaded ends of drill pipe joints. Drill pipe with tool joints and the pipe body are produced separately and are welded in the end. These are made to tolerate severe working conditions of drilling, delivering connections with high-strength and high-pressure threads.

Drill Pipe with Upset and Tool Joint Types

Drill pipe with tool joints can be determined by their configuration or upset on both ends. The upset of the drill pipe allows welding of the tool joints and can be categorized as:

- Internal Upset (IU): The drill pipe’s internal diameter is decreased and the outer diameter is maintained in a drill pipe with internal upset.

- External Upset (EU): Extra wall thickness is achieved with the drill pipe with external upset by increasing the outer diameter while maintaining the internal diameter at constant.

- Internal-External Upset (IEU): The inside diameter of a drill pipe with internal-external upset is decreased and its outside diameter increased.

Drill Pipe with Upset and Tool Joint Advantages

Drill pipe with upset provides three key advantages: (1) presence of a thicker and sturdier weld area; (2) better transition from harder tool joints to more flexible pipes; and (3) stressed areas being kept away from the weld region.

Understanding Drill Pipe Upset and Tool Joint Specifications

The drill pipe with upset is manufactured through a forging process where the tube ends are made with thicker walls. The process starts by heating the ends of the tube, followed by pressure application utilizing a closed die hydraulic forging press, which will create the upsets.

An external upset part with an outer taper is formed on one end of the steel tube through upsetting and pressing. Internal upset forging may then be initiated by displacing the outer taper to an internal upset part with an internal taper. This is done by pressing the external upset portion. An internal upset die can deliver the final part of the internal upset forging process.

Not all drill pipes are upset. This is secondary to the expenses required to successfully produce drill pipe with upset.

The Tool joints of the drill pipe are the enlarged and threaded ends of drill pipe joints. Drill pipe with tool joints and the pipe body are produced separately and are welded in the end. These are made to tolerate severe working conditions of drilling, delivering connections with high-strength and high-pressure threads.

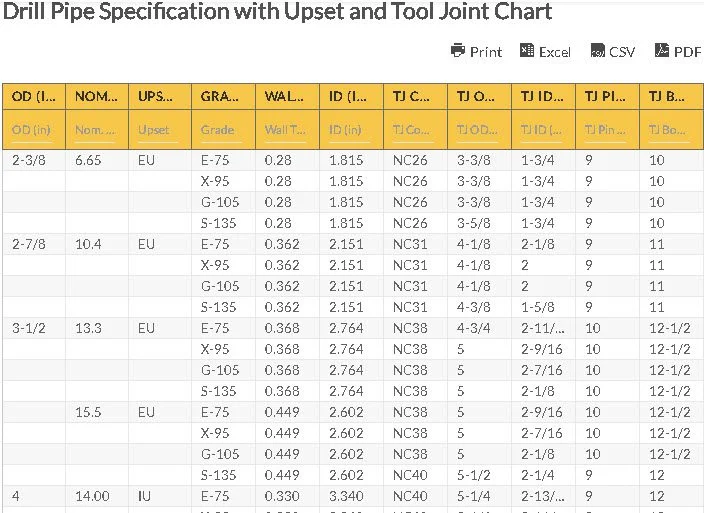

Understanding drill pipe upset configurations and tool joint specifications is essential for optimizing drill string performance, maximizing connection strength, and preventing premature failures in demanding drilling operations. The drill pipe specification chart below provides comprehensive dimensional data for internal upset (IU), external upset (EU), and internal-external upset (IEU) drill pipe configurations, along with corresponding tool joint dimensions, thread specifications, and makeup torque requirements. Proper selection of upset type depends on multiple factors including wellbore geometry, required internal drift diameter for downhole tools, drilling fluid hydraulics, and the balance between connection strength and pipe body flexibility. Internal upset drill pipe maintains constant outside diameter for improved hydraulics and reduced hole drag, while external upset configurations preserve full internal diameter for maximum drift clearance and tool passage. Internal-external upset pipe provides the strongest connections by increasing wall thickness in both directions, making it the preferred choice for high-torque directional drilling and extended reach applications where connection integrity is critical. These API specifications ensure standardized dimensions, interchangeability between manufacturers, and proven performance across global drilling operations from shallow vertical wells to complex ultra-deep offshore developments.

Drill Pipe Specification with Upset and Tool Joint Chart

| wdt_ID | OD (in) | Nom. Wt (lb/ft) | Upset | Grade | Wall Thkns (in) | ID (in) | TJ Conn Type | TJ OD (in) | TJ ID (in) | TJ Pin Tong Space (in) | TJ Box Tong Space (in) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2-3/8 | 6.65 | EU | E-75 | 0.28 | 1.815 | NC26 | 3-3/8 | 1-3/4 | 9 | 10 |

| 2 | X-95 | 0.28 | 1.815 | NC26 | 3-3/8 | 1-3/4 | 9 | 10 | |||

| 3 | G-105 | 0.28 | 1.815 | NC26 | 3-3/8 | 1-3/4 | 9 | 10 | |||

| 4 | S-135 | 0.28 | 1.815 | NC26 | 3-5/8 | 1-3/4 | 9 | 10 | |||

| 5 | 2-7/8 | 10.4 | EU | E-75 | 0.362 | 2.151 | NC31 | 4-1/8 | 2-1/8 | 9 | 11 |

| 6 | X-95 | 0.362 | 2.151 | NC31 | 4-1/8 | 2 | 9 | 11 | |||

| 7 | G-105 | 0.362 | 2.151 | NC31 | 4-1/8 | 2 | 9 | 11 | |||

| 8 | S-135 | 0.362 | 2.151 | NC31 | 4-3/8 | 1-5/8 | 9 | 11 | |||

| 9 | 3-1/2 | 13.3 | EU | E-75 | 0.368 | 2.764 | NC38 | 4-3/4 | 2-11/16 | 10 | 12-1/2 |

| 10 | X-95 | 0.368 | 2.764 | NC38 | 5 | 2-9/16 | 10 | 12-1/2 | |||

| 11 | G-105 | 0.368 | 2.764 | NC38 | 5 | 2-7/16 | 10 | 12-1/2 | |||

| 12 | S-135 | 0.368 | 2.764 | NC38 | 5 | 2-1/8 | 10 | 12-1/2 | |||

| 13 | 15.5 | EU | E-75 | 0.449 | 2.602 | NC38 | 5 | 2-9/16 | 10 | 12-1/2 | |

| 14 | X-95 | 0.449 | 2.602 | NC38 | 5 | 2-7/16 | 10 | 12-1/2 | |||

| 15 | G-105 | 0.449 | 2.602 | NC38 | 5 | 2-1/8 | 10 | 12-1/2 | |||

| 16 | S-135 | 0.449 | 2.602 | NC40 | 5-1/2 | 2-1/4 | 9 | 12 | |||

| 17 | 4 | 14.00 | IU | E-75 | 0.330 | 3.340 | NC40 | 5-1/4 | 2-13/16 | 9 | 12 |

| 18 | X-95 | 0.330 | 3.340 | NC40 | 5-1/4 | 2-11/16 | 9 | 12 | |||

| 19 | G-105 | 0.330 | 3.340 | NC40 | 5-1/2 | 2-7/16 | 9 | 12 | |||

| 20 | S-135 | 0.330 | 3.340 | NC40 | 5-1/2 | 2-7/16 | 9 | 12 | |||

| 21 | EU | E-75 | 0.330 | 3.340 | NC46 | 6 | 3-1/4 | 9 | 12 | ||

| 22 | X-95 | 0.330 | 3.340 | NC46 | 6 | 3-1/4 | 9 | 12 | |||

| 23 | G-105 | 0.330 | 3.340 | NC46 | 6 | 3-1/4 | 9 | 12 | |||

| 24 | S-135 | 0.330 | 3.340 | NC46 | 6 | 3 | 9 | 12 | |||

| 25 | 15.70 | IU | E-75 | 0.380 | 3.240 | NC40 | 5-1/4 | 2-11/16 | 9 | 12 | |

| 26 | X-95 | 0.380 | 3.240 | NC40 | 5-1/4 | 2-7/16 | 9 | 12 | |||

| 27 | G-105 | 0.380 | 3.240 | NC40 | 5-1/2 | 2-7/16 | 9 | 12 | |||

| 28 | S-135 | 0.380 | 3.240 | NC40 | 5-1/2 | 2 | 9 | 12 | |||

| 29 | EU | E-75 | 0.380 | 3.240 | NC46 | 6 | 3-1/4 | 9 | 12 | ||

| 30 | X-95 | 0.380 | 3.240 | NC46 | 6 | 3-1/4 | 9 | 12 | |||

| 31 | G-105 | 0.380 | 3.240 | NC46 | 6 | 3-1/4 | 9 | 12 | |||

| 32 | S-135 | 0.380 | 3.240 | NC46 | 6 | 3 | 9 | 12 | |||

| 33 | 4-1/2 | 16.60 | IEU | E-75 | 0.337 | 3.826 | NC46 | 6-1/4 | 3 | 9 | 12 |

| 34 | X-95 | 0.337 | 3.826 | NC46 | 6-1/4 | 3-1/4 | 9 | 12 | |||

| 35 | G-105 | 0.337 | 3.826 | NC46 | 6-1/4 | 3 | 9 | 12 | |||

| 36 | S-135 | 0.337 | 3.826 | NC46 | 6-1/4 | 2-3/4 | 9 | 12 | |||

| 37 | EU | E-75 | 0.337 | 3.826 | NC50 | 6-5/8 | 3-3/4 | 9 | 12 | ||

| 38 | X-95 | 0.337 | 3.826 | NC50 | 6-5/8 | 3-3/4 | 9 | 12 | |||

| 39 | G-105 | 0.337 | 3.826 | NC50 | 6-5/8 | 3-3/4 | 9 | 12 | |||

| 40 | S-135 | 0.337 | 3.826 | NC50 | 6-5/8 | 3-1/2 | 9 | 12 | |||

| 41 | 20.00 | IEU | E-75 | 0.430 | 3.640 | NC46 | 6-1/4 | 3 | 9 | 12 | |

| 42 | X-95 | 0.430 | 3.640 | NC46 | 6-1/4 | 2-3/4 | 9 | 12 | |||

| 43 | G-105 | 0.430 | 3.640 | NC46 | 6-1/4 | 2-1/2 | 9 | 12 | |||

| 44 | S-135 | 0.430 | 3.640 | NC46 | 6-1/4 | 2-1/4 | 9 | 12 | |||

| 45 | EU | E-75 | 0.430 | 3.640 | NC50 | 6-5/8 | 3-5/8 | 9 | 12 | ||

| 46 | X-95 | 0.430 | 3.640 | NC50 | 6-5/8 | 3-1/2 | 9 | 12 | |||

| 47 | G-105 | 0.430 | 3.640 | NC50 | 6-5/8 | 3-1/2 | 9 | 12 | |||

| 48 | S-135 | 0.430 | 3.640 | NC50 | 6-5/8 | 3 | 9 | 12 | |||

| 49 | 5 | 19.50 | IEU | E-75 | 0.362 | 4.276 | NC50 | 6-5/8 | 3-3/4 | 9 | 12 |

| 50 | X-95 | 0.362 | 4.276 | NC50 | 6-5/8 | 3-1/2 | 9 | 12 |

Drill Pipe Specification with Upset and Tool Joint Chart

| wdt_ID | OD (in) | Nom. Wt (lb/ft) | Upset | Grade | Wall Thkns (in) | ID (in) | TJ Conn Type | TJ OD (in) | TJ ID (in) | TJ Pin Tong Space (in) | TJ Box Tong Space (in) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2-3/8 | 6.65 | EU | E-75 | 0.28 | 1.815 | NC26 | 3-3/8 | 1-3/4 | 9 | 10 |

| 2 | X-95 | 0.28 | 1.815 | NC26 | 3-3/8 | 1-3/4 | 9 | 10 | |||

| 3 | G-105 | 0.28 | 1.815 | NC26 | 3-3/8 | 1-3/4 | 9 | 10 | |||

| 4 | S-135 | 0.28 | 1.815 | NC26 | 3-5/8 | 1-3/4 | 9 | 10 | |||

| 5 | 2-7/8 | 10.4 | EU | E-75 | 0.362 | 2.151 | NC31 | 4-1/8 | 2-1/8 | 9 | 11 |

| 6 | X-95 | 0.362 | 2.151 | NC31 | 4-1/8 | 2 | 9 | 11 | |||

| 7 | G-105 | 0.362 | 2.151 | NC31 | 4-1/8 | 2 | 9 | 11 | |||

| 8 | S-135 | 0.362 | 2.151 | NC31 | 4-3/8 | 1-5/8 | 9 | 11 | |||

| 9 | 3-1/2 | 13.3 | EU | E-75 | 0.368 | 2.764 | NC38 | 4-3/4 | 2-11/16 | 10 | 12-1/2 |

| 10 | X-95 | 0.368 | 2.764 | NC38 | 5 | 2-9/16 | 10 | 12-1/2 | |||

| 11 | G-105 | 0.368 | 2.764 | NC38 | 5 | 2-7/16 | 10 | 12-1/2 | |||

| 12 | S-135 | 0.368 | 2.764 | NC38 | 5 | 2-1/8 | 10 | 12-1/2 | |||

| 13 | 15.5 | EU | E-75 | 0.449 | 2.602 | NC38 | 5 | 2-9/16 | 10 | 12-1/2 | |

| 14 | X-95 | 0.449 | 2.602 | NC38 | 5 | 2-7/16 | 10 | 12-1/2 | |||

| 15 | G-105 | 0.449 | 2.602 | NC38 | 5 | 2-1/8 | 10 | 12-1/2 | |||

| 16 | S-135 | 0.449 | 2.602 | NC40 | 5-1/2 | 2-1/4 | 9 | 12 | |||

| 17 | 4 | 14.00 | IU | E-75 | 0.330 | 3.340 | NC40 | 5-1/4 | 2-13/16 | 9 | 12 |

| 18 | X-95 | 0.330 | 3.340 | NC40 | 5-1/4 | 2-11/16 | 9 | 12 | |||

| 19 | G-105 | 0.330 | 3.340 | NC40 | 5-1/2 | 2-7/16 | 9 | 12 | |||

| 20 | S-135 | 0.330 | 3.340 | NC40 | 5-1/2 | 2-7/16 | 9 | 12 | |||

| 21 | EU | E-75 | 0.330 | 3.340 | NC46 | 6 | 3-1/4 | 9 | 12 | ||

| 22 | X-95 | 0.330 | 3.340 | NC46 | 6 | 3-1/4 | 9 | 12 | |||

| 23 | G-105 | 0.330 | 3.340 | NC46 | 6 | 3-1/4 | 9 | 12 | |||

| 24 | S-135 | 0.330 | 3.340 | NC46 | 6 | 3 | 9 | 12 | |||

| 25 | 15.70 | IU | E-75 | 0.380 | 3.240 | NC40 | 5-1/4 | 2-11/16 | 9 | 12 | |

| 26 | X-95 | 0.380 | 3.240 | NC40 | 5-1/4 | 2-7/16 | 9 | 12 | |||

| 27 | G-105 | 0.380 | 3.240 | NC40 | 5-1/2 | 2-7/16 | 9 | 12 | |||

| 28 | S-135 | 0.380 | 3.240 | NC40 | 5-1/2 | 2 | 9 | 12 | |||

| 29 | EU | E-75 | 0.380 | 3.240 | NC46 | 6 | 3-1/4 | 9 | 12 | ||

| 30 | X-95 | 0.380 | 3.240 | NC46 | 6 | 3-1/4 | 9 | 12 | |||

| 31 | G-105 | 0.380 | 3.240 | NC46 | 6 | 3-1/4 | 9 | 12 | |||

| 32 | S-135 | 0.380 | 3.240 | NC46 | 6 | 3 | 9 | 12 | |||

| 33 | 4-1/2 | 16.60 | IEU | E-75 | 0.337 | 3.826 | NC46 | 6-1/4 | 3 | 9 | 12 |

| 34 | X-95 | 0.337 | 3.826 | NC46 | 6-1/4 | 3-1/4 | 9 | 12 | |||

| 35 | G-105 | 0.337 | 3.826 | NC46 | 6-1/4 | 3 | 9 | 12 | |||

| 36 | S-135 | 0.337 | 3.826 | NC46 | 6-1/4 | 2-3/4 | 9 | 12 | |||

| 37 | EU | E-75 | 0.337 | 3.826 | NC50 | 6-5/8 | 3-3/4 | 9 | 12 | ||

| 38 | X-95 | 0.337 | 3.826 | NC50 | 6-5/8 | 3-3/4 | 9 | 12 | |||

| 39 | G-105 | 0.337 | 3.826 | NC50 | 6-5/8 | 3-3/4 | 9 | 12 | |||

| 40 | S-135 | 0.337 | 3.826 | NC50 | 6-5/8 | 3-1/2 | 9 | 12 | |||

| 41 | 20.00 | IEU | E-75 | 0.430 | 3.640 | NC46 | 6-1/4 | 3 | 9 | 12 | |

| 42 | X-95 | 0.430 | 3.640 | NC46 | 6-1/4 | 2-3/4 | 9 | 12 | |||

| 43 | G-105 | 0.430 | 3.640 | NC46 | 6-1/4 | 2-1/2 | 9 | 12 | |||

| 44 | S-135 | 0.430 | 3.640 | NC46 | 6-1/4 | 2-1/4 | 9 | 12 | |||

| 45 | EU | E-75 | 0.430 | 3.640 | NC50 | 6-5/8 | 3-5/8 | 9 | 12 | ||

| 46 | X-95 | 0.430 | 3.640 | NC50 | 6-5/8 | 3-1/2 | 9 | 12 | |||

| 47 | G-105 | 0.430 | 3.640 | NC50 | 6-5/8 | 3-1/2 | 9 | 12 | |||

| 48 | S-135 | 0.430 | 3.640 | NC50 | 6-5/8 | 3 | 9 | 12 | |||

| 49 | 5 | 19.50 | IEU | E-75 | 0.362 | 4.276 | NC50 | 6-5/8 | 3-3/4 | 9 | 12 |

| 50 | X-95 | 0.362 | 4.276 | NC50 | 6-5/8 | 3-1/2 | 9 | 12 |

Drill Pipe Specification with Upset and Tool Joint Chart Abbreviations:

- OD – Outside Diameter

- ID – Inside Diameter

- Nom. Wt – Nominal Weight

- Wall Thkns – Wall Thickness

- TJ – Tool Joint

The drill pipe specifications with upset and tool joints provides data on the pipe body and tool joints. The pipe body details include:

- Size OD (outer diameter) in inches

- Nominal weight in lb/ft

- Upset Type (IU, EU, IEU)

- Grade which shows the kind of steel, tensile strength, and yield strength

- Wall Thickness in inches

- Inner diameter (ID) in inches

The tool joint details include:

- Connection type or portion of the piping system where joints connect the pipe

- Outer and inner diameter configurations

- Pin Tong and Box Tong space, which is a usable tong space for pin and box tool joints

Sourcing Quality Upset Drill Pipe and Tool Joints for Reliable Drilling Performance

Selecting the appropriate upset configuration and tool joint specifications is fundamental to building drill strings that deliver reliable performance, minimize connection failures, and optimize drilling economics across diverse wellbore applications. The charts above provide the technical foundation for drill pipe procurement decisions, but successful drilling operations also require understanding how upset type, tool joint design, and connection specifications interact with your specific drilling parameters including torque requirements, hydraulic efficiency, and downhole tool compatibility. Flowtech Energy maintains comprehensive inventory of API-certified drill pipe in all standard upset configurations—internal upset (IU), external upset (EU), and internal-external upset (IEU)—with premium tool joint connections manufactured to withstand the most demanding drilling environments.

Our drill pipe inventory includes both new premium pipe and thoroughly inspected used pipe that has been evaluated according to API RP 7G standards, with detailed documentation of tube wall thickness, upset dimensions, tool joint condition, and thread integrity. We understand that drill pipe represents a major capital investment, and our technical team provides engineering support to help optimize drill string design, evaluate cost-effective alternatives using certified used pipe, and coordinate delivery schedules that support your drilling program timeline. Whether you’re drilling conventional vertical wells, complex directional trajectories, or extended reach horizontal wells requiring maximum connection strength and fatigue resistance, we deliver expert guidance on upset type selection, tool joint specifications, and procurement strategies that balance performance requirements with project economics. If you need assistance selecting appropriate drill pipe upset configurations for your drilling application, sourcing certified pipe with complete inspection documentation and material traceability, or coordinating delivery and field support for drilling operations, contact Flowtech Energy at 1-877-645-6693. We provide comprehensive drill pipe procurement solutions—ensuring your drilling operations have the right equipment specifications to achieve wellbore objectives safely and efficiently while maximizing drill string reliability and minimizing non-productive time in challenging drilling environments.

Go here if you are looking for the Drill Rod Thread Compatibility Chart.