Line Pipe Schedule 140 Dimension, Weight and Thickness Chart

Piping schedule refers to the pipe’s thickness. Schedule 140 is a pipe’s thickness designator. The American Society of Mechanical Engineers assigned the schedule number to combine the pipe’s diameter and wall thickness. It replaces and simplifies the old system where line pipe is available in only three sizes such as double extra-strong (XXS), standard weight (STD), and extra-strong (XS) – all based on the iron pipe size or IPS system.

The schedule number (140) is equivalent to the pressure and stress that are both measured in pounds per square inch (psi).Schedule number = p/s

P – the service pressure

S – the allowable stress

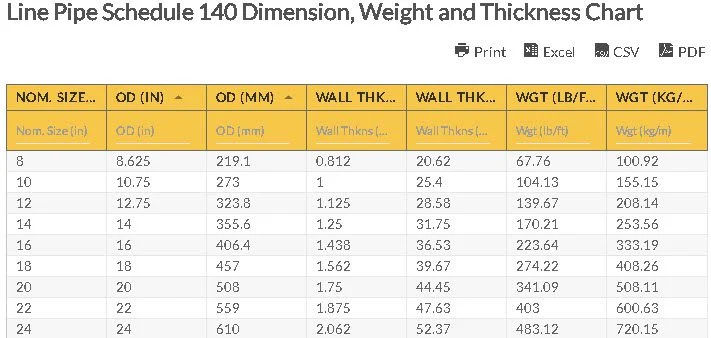

Line Pipe Schedule 140 Dimension, Weight, and Thickness Chart

The Line Pipe Schedule 140 Dimension, Weight, and Thickness Chart shows the exact numerical values for each nominal size and corresponding dimensions (diameter, thickness) and weight. The chart or table is useful for specifying the best pipe for drilling completion. It allows one to determine the pipe that is compatible with other drill pipe components, as well as the pipe that is best for certain underground conditions.

| wdt_ID | Nom. Size (in) | OD (in) | OD (mm) | Wall Thkns (in) | Wall Thkns (mm) | Wgt (lb/ft) | Wgt (kg/m) |

|---|---|---|---|---|---|---|---|

| 1 | 8 | 8.625 | 219.1 | 0.812 | 20.62 | 67.76 | 100.92 |

| 2 | 10 | 10.75 | 273 | 1 | 25.4 | 104.13 | 155.15 |

| 3 | 12 | 12.75 | 323.8 | 1.125 | 28.58 | 139.67 | 208.14 |

| 4 | 14 | 14 | 355.6 | 1.25 | 31.75 | 170.21 | 253.56 |

| 5 | 16 | 16 | 406.4 | 1.438 | 36.53 | 223.64 | 333.19 |

| 6 | 18 | 18 | 457 | 1.562 | 39.67 | 274.22 | 408.26 |

| 7 | 20 | 20 | 508 | 1.75 | 44.45 | 341.09 | 508.11 |

| 8 | 22 | 22 | 559 | 1.875 | 47.63 | 403 | 600.63 |

| 9 | 24 | 24 | 610 | 2.062 | 52.37 | 483.12 | 720.15 |

| wdt_ID | Nom. Size (in) | OD (in) | OD (mm) | Wall Thkns (in) | Wall Thkns (mm) | Wgt (lb/ft) | Wgt (kg/m) |

|---|---|---|---|---|---|---|---|

| 1 | 8 | 8.625 | 219.1 | 0.812 | 20.62 | 67.76 | 100.92 |

| 2 | 10 | 10.75 | 273 | 1 | 25.4 | 104.13 | 155.15 |

| 3 | 12 | 12.75 | 323.8 | 1.125 | 28.58 | 139.67 | 208.14 |

| 4 | 14 | 14 | 355.6 | 1.25 | 31.75 | 170.21 | 253.56 |

| 5 | 16 | 16 | 406.4 | 1.438 | 36.53 | 223.64 | 333.19 |

| 6 | 18 | 18 | 457 | 1.562 | 39.67 | 274.22 | 408.26 |

| 7 | 20 | 20 | 508 | 1.75 | 44.45 | 341.09 | 508.11 |

| 8 | 22 | 22 | 559 | 1.875 | 47.63 | 403 | 600.63 |

| 9 | 24 | 24 | 610 | 2.062 | 52.37 | 483.12 | 720.15 |

Line Pipe SCH 140: Definition of Dimensional Values

The Table for Line Pipe Schedule 140 Dimension, Weight, and Thickness constitutes rows for nominal sizes and columns for dimensional values.

Nominal size is the non-specific term used for non-approximate values. It refers to the outside diameter. A 2 nominal pipe size means a pipe with 2.375 inches on its outside diameter regardless of wall thickness. An increase in the schedule (SCH) increments the mechanical pipe strength and allows it to withstand higher pressures.

Outside diameter is the measurement from the outer wall to the other side – top to bottom and left to right. To calculate the outside diameter, use this formula:

Outside diameter = ID + Wall thickness (2x)

Wall thickness is expressed in pipe schedule. The wall thickness measures the pipe’s wall in inches or millimeters. To calculate the wall thickness based on ID and OD, here is the formula:

Wall thickness = ID – OD / 2

Weight defines the pipe’s weight per foot or pound.

Line Pipe Schedule 140 Dimensions

The Line Pipe Schedule 140 Dimension, Thickness, and Weight Table shows that an increase in nominal size also increments the outside diameter (millimeters), wall thickness (inches and millimeter), and weight (kg/m) except for the outside diameter.

For example, in stainless steel pipes and tubes, the formula for Outer Diameter would be the following:

OD (mm) – W.T (mm) X W.T (mm) x 0.02466 = kilogram per meter.

Line Pipe Schedule 140 Dimensions Chart Abbreviations:

- OD – Outside Diameter

- in – inches

- mm – millimeter

- lb/ft – pounds per feet

- kg/m – kilogram per meter

- Wgt – Weight

- Nom. Size – Nominal Size

- Wall Thkns – Wall Thickness

Selecting Schedule 140 Line Pipe for Ultra-High Pressure Pipeline Applications

When designing pipeline systems for the most extreme pressure environments in the oil and gas industry, Schedule 140 line pipe delivers the exceptional wall thickness and structural integrity required for ultra-high pressure applications where operational reliability is absolutely critical. The Line Pipe Schedule 140 Dimension, Weight and Thickness Chart provides essential reference data that helps engineers and procurement specialists select the appropriate heavy-duty pipe specifications based on extreme pressure requirements, maximum safety factors, and specialized operational parameters. At FlowTech Energy, we maintain a specialized inventory of Schedule 140 line pipe to support the most demanding pipeline projects where standard schedules would be insufficient for safe, long-term operation.

Our technical experts understand that selecting the appropriate schedule is paramount for ensuring both safety and reliability in ultra-high pressure pipeline systems. Schedule 140 pipe represents the pinnacle of wall thickness for applications where maximum pressure resistance is non-negotiable, such as high-pressure injection systems, specialized transmission lines, or applications with severe service conditions. Contact us today at 1-877-645-6693 to discuss how our inventory of premium Schedule 140 line pipe can provide the robust solution your ultra-high pressure pipeline project demands. Whether you’re designing new critical infrastructure or upgrading existing systems to handle increased operating pressures, our selection of API-compliant Schedule 140 line pipe ensures you’ll find the exact specifications needed to maximize both safety margins and operational confidence throughout your pipeline system’s lifecycle, even under the most extreme pressure conditions.

Go here if you are looking for the Line Pipe Schedule 160 Dimension, Weight and Thickness Chart