Line Pipe Schedule and Thickness Chart

Line Pipe Schedule and Thickness

Line pipe schedule is the expression used to define the thickness of the line pipe. For some pipe with a particular nominal diameter, the outside diameter (OD) is similar for all line pipe schedules. Standard line pipe schedule and thickness is established through the API 5L and ANSI (American National Standards Institute)/ASME (American Society of Mechanical Engineers) B36.10M, with 11 commonly used line pipe schedule and thickness numbers: 5, 10, 20, 30, 40, 60, 80, 100, 120, 140, and 160.

Today, the most widely used line pipe schedule is 40, while schedules 5, 60, 100, 120, and 140 are utilized only for specific piping projects. Line pipe schedule 40 and standard weight (STD) line pipe thickness are the same for pipe that measures 8 inches and below.

Line Pipe Schedule and Thickness Computation

The line pipe schedule number is identified as the estimated value of the expression: Schedule number = (1000) (P/S) Where:

- P = internal working pressure (psig)

- S = allowable stress (psi) with respect to the material of construction at a given environment.

To determine the line pipe schedule, the inside diameter of the pipe must be measured and divided by the wall thickness in inches.

Line Pipe Schedule and Thickness Significance

Line pipe schedule and thickness are critical points for operators of industries that utilize the pipe for conveyance of highly pressurized fluids like oil and natural gas. The schedule and thickness of the line pipe denote its strength and are defined by the ASME standard, depending on the nominal pipe size. The outside diameter of the pipe usually remains at the same measurement; differences made in the line pipe thickness, therefore, affects the inner diameter. A higher line pipe schedule means an increase in the line pipe thicknessand a reduction on the nominal bore.

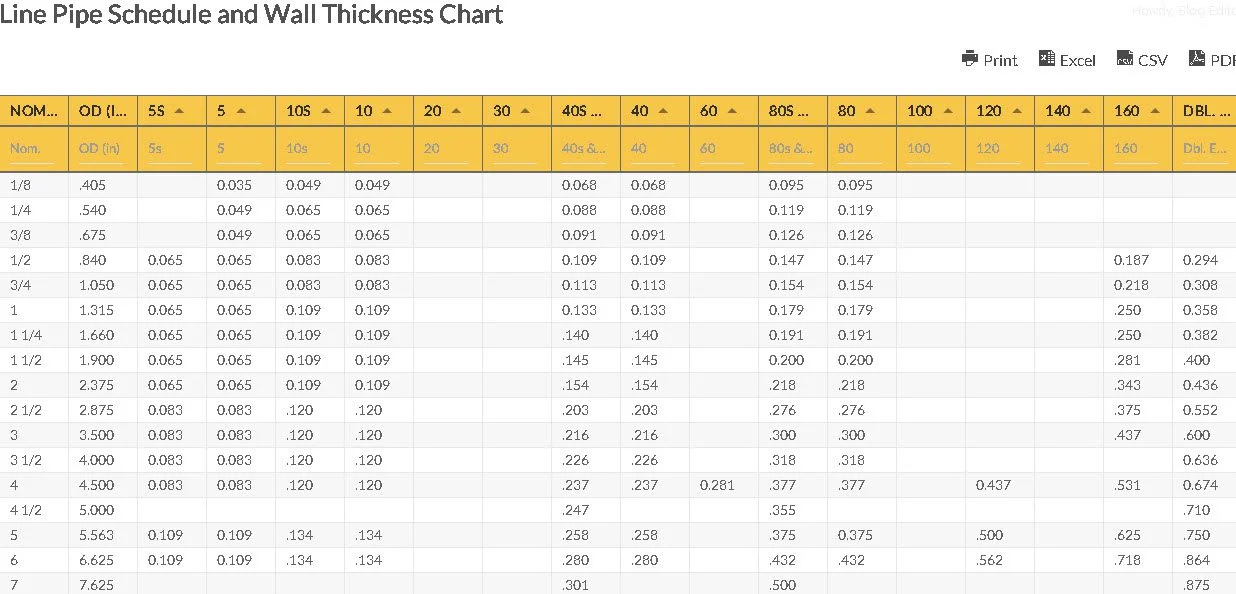

Line Pipe Schedule and Wall Thickness Chart

| wdt_ID | Nom. | OD (in) | 5s | 5 | 10s | 10 | 20 | 30 | 40s & Std | 40 | 60 | 80s & E.H. | 80 | 100 | 120 | 140 | 160 | Dbl. E.H. (XXH) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1/8 | .405 | 0.035 | 0.049 | 0.049 | 0.068 | 0.068 | 0.095 | 0.095 | |||||||||

| 2 | 1/4 | .540 | 0.049 | 0.065 | 0.065 | 0.088 | 0.088 | 0.119 | 0.119 | |||||||||

| 3 | 3/8 | .675 | 0.049 | 0.065 | 0.065 | 0.091 | 0.091 | 0.126 | 0.126 | |||||||||

| 4 | 1/2 | .840 | 0.065 | 0.065 | 0.083 | 0.083 | 0.109 | 0.109 | 0.147 | 0.147 | 0.187 | 0.294 | ||||||

| 5 | 3/4 | 1.050 | 0.065 | 0.065 | 0.083 | 0.083 | 0.113 | 0.113 | 0.154 | 0.154 | 0.218 | 0.308 | ||||||

| 6 | 1 | 1.315 | 0.065 | 0.065 | 0.109 | 0.109 | 0.133 | 0.133 | 0.179 | 0.179 | .250 | 0.358 | ||||||

| 7 | 1 1/4 | 1.660 | 0.065 | 0.065 | 0.109 | 0.109 | .140 | .140 | 0.191 | 0.191 | .250 | 0.382 | ||||||

| 8 | 1 1/2 | 1.900 | 0.065 | 0.065 | 0.109 | 0.109 | .145 | .145 | 0.200 | 0.200 | .281 | .400 | ||||||

| 9 | 2 | 2.375 | 0.065 | 0.065 | 0.109 | 0.109 | .154 | .154 | .218 | .218 | .343 | 0.436 | ||||||

| 10 | 2 1/2 | 2.875 | 0.083 | 0.083 | .120 | .120 | .203 | .203 | .276 | .276 | .375 | 0.552 | ||||||

| 11 | 3 | 3.500 | 0.083 | 0.083 | .120 | .120 | .216 | .216 | .300 | .300 | .437 | .600 | ||||||

| 12 | 3 1/2 | 4.000 | 0.083 | 0.083 | .120 | .120 | .226 | .226 | .318 | .318 | 0.636 | |||||||

| 13 | 4 | 4.500 | 0.083 | 0.083 | .120 | .120 | .237 | .237 | 0.281 | .377 | .377 | 0.437 | .531 | 0.674 | ||||

| 14 | 4 1/2 | 5.000 | .247 | .355 | .710 | |||||||||||||

| 15 | 5 | 5.563 | 0.109 | 0.109 | .134 | .134 | .258 | .258 | .375 | 0.375 | .500 | .625 | .750 | |||||

| 16 | 6 | 6.625 | 0.109 | 0.109 | .134 | .134 | .280 | .280 | .432 | .432 | .562 | .718 | .864 | |||||

| 17 | 7 | 7.625 | .301 | .500 | .875 | |||||||||||||

| 18 | 8 | 8.625 | 0.109 | 0.109 | .148 | .148 | .250 | 0.277 | .322 | .322 | 0.406 | .500 | .500 | 0.593 | .718 | 0.812 | .906 | .875 |

| 19 | 9 | 9.625 | .342 | .500 | ||||||||||||||

| 20 | 10 | 10.750 | 0.134 | 0.134 | .165 | .165 | .250 | 0.307 | .365 | .365 | .500 | .500 | .593 | 0.718 | .843 | 1.000 | 1.125 | |

| 21 | 11 | 11.750 | .375 | .500 | ||||||||||||||

| 22 | 12 | 12.750 | 0.156 | 0.165 | .180 | .180 | .250 | .330 | .375 | .406 | .562 | .500 | .687 | 0.843 | 1.000 | 1.125 | 1.312 | |

| 23 | 14 | 14.000 | 0.156 | .188 | .250 | .312 | .375 | .375 | .437 | .593 | .500 | .750 | 0.937 | 1.093 | 1.250 | 1.406 | ||

| 24 | 16 | 16.000 | 0.165 | .188 | .250 | .312 | .375 | .375 | .500 | .656 | .500 | .843 | 1.031 | 1.218 | 1.437 | 1.593 | ||

| 25 | 18 | 18.000 | 0.165 | .188 | .250 | .312 | .437 | .375 | .562 | .750 | .500 | .937 | 1.156 | 1.375 | 1.562 | 1.781 | ||

| 26 | 20 | 20.000 | 0.188 | .218 | .250 | .375 | .500 | .375 | .593 | .812 | .500 | 1.031 | 1.280 | 1.500 | 1.750 | 1.968 | ||

| 27 | 24 | 24.000 | 0.218 | .250 | .250 | .375 | .562 | .375 | .687 | .968 | .500 | 1.218 | 1.531 | 1.812 | 2.052 | 2.343 | ||

| 28 | 26 | 26.000 | .312 | .500 | .375 | .500 | ||||||||||||

| 29 | 28 | 28.000 | 312 | .500 | .625 | .375 | ||||||||||||

| 30 | 30 | 30.000 | .250 | .312 | .312 | .500 | .625 | .375 | .500 | |||||||||

| 31 | 32 | 32.000 | .312 | .500 | .625 | .375 | .688 | .500 | ||||||||||

| 32 | 34 | 34.00 | .312 | .500 | .625 | .375 | .688 | |||||||||||

| 33 | 36 | 36.000 | .312 | .625 | .375 | .750 | .500 | |||||||||||

| 34 | 42 | 42.000 | .375 | .500 | ||||||||||||||

| 35 | 48 | 48.000 | .375 | .500 |

| wdt_ID | Nom. | OD (in) | 5s | 5 | 10s | 10 | 20 | 30 | 40s & Std | 40 | 60 | 80s & E.H. | 80 | 100 | 120 | 140 | 160 | Dbl. E.H. (XXH) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1/8 | .405 | 0.035 | 0.049 | 0.049 | 0.068 | 0.068 | 0.095 | 0.095 | |||||||||

| 2 | 1/4 | .540 | 0.049 | 0.065 | 0.065 | 0.088 | 0.088 | 0.119 | 0.119 | |||||||||

| 3 | 3/8 | .675 | 0.049 | 0.065 | 0.065 | 0.091 | 0.091 | 0.126 | 0.126 | |||||||||

| 4 | 1/2 | .840 | 0.065 | 0.065 | 0.083 | 0.083 | 0.109 | 0.109 | 0.147 | 0.147 | 0.187 | 0.294 | ||||||

| 5 | 3/4 | 1.050 | 0.065 | 0.065 | 0.083 | 0.083 | 0.113 | 0.113 | 0.154 | 0.154 | 0.218 | 0.308 | ||||||

| 6 | 1 | 1.315 | 0.065 | 0.065 | 0.109 | 0.109 | 0.133 | 0.133 | 0.179 | 0.179 | .250 | 0.358 | ||||||

| 7 | 1 1/4 | 1.660 | 0.065 | 0.065 | 0.109 | 0.109 | .140 | .140 | 0.191 | 0.191 | .250 | 0.382 | ||||||

| 8 | 1 1/2 | 1.900 | 0.065 | 0.065 | 0.109 | 0.109 | .145 | .145 | 0.200 | 0.200 | .281 | .400 | ||||||

| 9 | 2 | 2.375 | 0.065 | 0.065 | 0.109 | 0.109 | .154 | .154 | .218 | .218 | .343 | 0.436 | ||||||

| 10 | 2 1/2 | 2.875 | 0.083 | 0.083 | .120 | .120 | .203 | .203 | .276 | .276 | .375 | 0.552 | ||||||

| 11 | 3 | 3.500 | 0.083 | 0.083 | .120 | .120 | .216 | .216 | .300 | .300 | .437 | .600 | ||||||

| 12 | 3 1/2 | 4.000 | 0.083 | 0.083 | .120 | .120 | .226 | .226 | .318 | .318 | 0.636 | |||||||

| 13 | 4 | 4.500 | 0.083 | 0.083 | .120 | .120 | .237 | .237 | 0.281 | .377 | .377 | 0.437 | .531 | 0.674 | ||||

| 14 | 4 1/2 | 5.000 | .247 | .355 | .710 | |||||||||||||

| 15 | 5 | 5.563 | 0.109 | 0.109 | .134 | .134 | .258 | .258 | .375 | 0.375 | .500 | .625 | .750 | |||||

| 16 | 6 | 6.625 | 0.109 | 0.109 | .134 | .134 | .280 | .280 | .432 | .432 | .562 | .718 | .864 | |||||

| 17 | 7 | 7.625 | .301 | .500 | .875 | |||||||||||||

| 18 | 8 | 8.625 | 0.109 | 0.109 | .148 | .148 | .250 | 0.277 | .322 | .322 | 0.406 | .500 | .500 | 0.593 | .718 | 0.812 | .906 | .875 |

| 19 | 9 | 9.625 | .342 | .500 | ||||||||||||||

| 20 | 10 | 10.750 | 0.134 | 0.134 | .165 | .165 | .250 | 0.307 | .365 | .365 | .500 | .500 | .593 | 0.718 | .843 | 1.000 | 1.125 | |

| 21 | 11 | 11.750 | .375 | .500 | ||||||||||||||

| 22 | 12 | 12.750 | 0.156 | 0.165 | .180 | .180 | .250 | .330 | .375 | .406 | .562 | .500 | .687 | 0.843 | 1.000 | 1.125 | 1.312 | |

| 23 | 14 | 14.000 | 0.156 | .188 | .250 | .312 | .375 | .375 | .437 | .593 | .500 | .750 | 0.937 | 1.093 | 1.250 | 1.406 | ||

| 24 | 16 | 16.000 | 0.165 | .188 | .250 | .312 | .375 | .375 | .500 | .656 | .500 | .843 | 1.031 | 1.218 | 1.437 | 1.593 | ||

| 25 | 18 | 18.000 | 0.165 | .188 | .250 | .312 | .437 | .375 | .562 | .750 | .500 | .937 | 1.156 | 1.375 | 1.562 | 1.781 | ||

| 26 | 20 | 20.000 | 0.188 | .218 | .250 | .375 | .500 | .375 | .593 | .812 | .500 | 1.031 | 1.280 | 1.500 | 1.750 | 1.968 | ||

| 27 | 24 | 24.000 | 0.218 | .250 | .250 | .375 | .562 | .375 | .687 | .968 | .500 | 1.218 | 1.531 | 1.812 | 2.052 | 2.343 | ||

| 28 | 26 | 26.000 | .312 | .500 | .375 | .500 | ||||||||||||

| 29 | 28 | 28.000 | 312 | .500 | .625 | .375 | ||||||||||||

| 30 | 30 | 30.000 | .250 | .312 | .312 | .500 | .625 | .375 | .500 | |||||||||

| 31 | 32 | 32.000 | .312 | .500 | .625 | .375 | .688 | .500 | ||||||||||

| 32 | 34 | 34.00 | .312 | .500 | .625 | .375 | .688 | |||||||||||

| 33 | 36 | 36.000 | .312 | .625 | .375 | .750 | .500 | |||||||||||

| 34 | 42 | 42.000 | .375 | .500 | ||||||||||||||

| 35 | 48 | 48.000 | .375 | .500 |

The line pipe schedule, abbreviated as SCH, can be classified as standard weight or STD; extra-strong or XS; extra-heavy or XH; double extra-strong or XXS; or double extra-heavy or XXH. SCH 40 for line pipe with NPS 1/8” to NPS 10” is the same as STD. SCH 80 for the line pipe with NPS 1/8” to NPS 8” is similar to XS or XH. SCH 160 on line pipe from NPS 1/8” to NPS 6” is thinner than XXS or XXH but thicker than XXS or XXH for line pipe with NPS 8” and larger. The line pipe schedule related to a certain line pipe thickness depends on the nominal pipe size. Standard steel pipe is commonly available in standard weight (STD) but may also be availed in other schedules.

Line Pipe Schedule and Thickness Chart Abbreviations:

- Nom. – Nominal Pipe Size

- O.D. – Outer Diameter

- Std. – Standard

- E.H. – Extra Heavy

- Double E.H. or XXH – Double Extra Heavy

Go here if you are looking for the Line Pipe OD, ID, Weight and Schedule Chart.