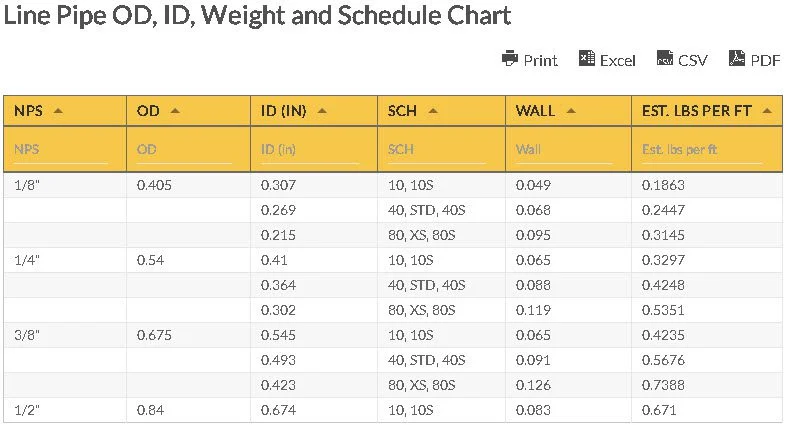

Line Pipe OD, ID, Weight and Schedule Chart

In the past, line pipe came only in three standard sizes: extra strong (XS), standard weight (STD), and double extra-strong (XXS). However, line pipe is now used in more varied conditions and industries, so the previous three sizes are no longer sufficient. It is for this reason that the industry came up with the pipe schedule concept.

Line Pipe OD, ID, Weight and Schedule

NPS stands for Nominal Pipe Size, which is basically the number that represents the pipe size. For instance, a pipe that measures six inches has a nominal pipe size of six inches. However, that is not definitive, as it still depends on the size of the pipe. For sizes NPS 14 and higher, NPS is the same as the OD or Outside Diameter.

The concept is easier to understand when you have knowledge on how line pipe is manufactured. For NPS 1/8 to NPS 12 pipe, the outside diameter is fixed. This means that if there is any increase in wall thickness, it would be the ID or inside diameter that will decrease. In this case, the line pipe ID is equal (approximately) to the NPS.

For sizes bigger than NPS 12, NPS stands for the actual OD of the line pipe. Any wall thickness variation will not affect NPS, just the ID or inside diameter.

Pipe Schedule Chart

To understand the pipe schedule better, here is the Line Pipe OD, ID, Weight and Schedule Chart:

| wdt_ID | NPS | OD | ID (in) | SCH | Wall | Est. lbs per ft |

|---|---|---|---|---|---|---|

| 243 | 11.75 | XS, 80S | 0.5 | 65.42 | ||

| 242 | 11.938 | 40 | 0.406 | 53.52 | ||

| 241 | 12 | STD, 40S | 0.375 | 49.56 | ||

| 240 | 12.09 | 30 | 0.33 | 43.77 | ||

| 239 | 12.25 | 20 | 0.25 | 33.38 | ||

| 238 | 12" | 12.75 | 12.39 | 10, 10S | 0.18 | 24.16 |

| 237 | 8.5 | 160 | 1.125 | 115.6 | ||

| 236 | 8.75 | 140, XX | 1 | 104.1 | ||

| 235 | 9.064 | 120 | 0.844 | 82.29 | ||

| 234 | 9.314 | 100 | 0.719 | 77.03 | ||

| 233 | 9.564 | 80 | 0.594 | 64.43 | ||

| 232 | 9.75 | 60, XS, 80S | 0.5 | 54.74 | ||

| 231 | 10.02 | 40, STD, 40S | 0.365 | 40.48 | ||

| 230 | 10.136 | 30 | 0.307 | 34.24 | ||

| 229 | 10.25 | 20 | 0.25 | 28.04 | ||

| 228 | 10" | 10.75 | 10.42 | 10, 10S | 0.165 | 18.65 |

| 227 | 6.875 | XX | 0.875 | 72.42 | ||

| 226 | 6.813 | 160 | 0.906 | 74.79 | ||

| 225 | 7.001 | 140 | 0.812 | 67.76 | ||

| 224 | 7.189 | 120 | 0.719 | 61.71 | ||

| 223 | 7.439 | 100 | 0.594 | 50.95 | ||

| 222 | 7.625 | 80, XS, 80S | 0.5 | 43.39 | ||

| 221 | 7.813 | 60 | 0.406 | 35.64 | ||

| 220 | 7.981 | 40, STD, 40S | 0.322 | 28.55 | ||

| 219 | 8.071 | 30 | 0.277 | 24.7 | ||

| 218 | 8.125 | 20 | 0.25 | 22.36 | ||

| 217 | 8" | 8.625 | 8.329 | 10, 10S | 0.148 | 13.4 |

| 216 | 4.897 | XX | 0.864 | 53.16 | ||

| 215 | 5.189 | 160 | 0.719 | 43.35 | ||

| 214 | 5.501 | 120 | 0.562 | 35.39 | ||

| 213 | 5.761 | 80, XS, 80S | 0.432 | 28.57 | ||

| 212 | 6.065 | 40, STD, 40S | 0.28 | 18.97 | ||

| 211 | 6" | 6.625 | 6.357 | 10, 10S | 0.134 | 9.29 |

| 210 | 4.063 | XX | 0.75 | 38.55 | ||

| 209 | 4.313 | 160 | 0.625 | 32.96 | ||

| 208 | 4.563 | 120 | 0.5 | 27.04 | ||

| 207 | 4.813 | 80, XS, 80S | 0.375 | 20.78 | ||

| 206 | 5.047 | 40, STD, 40S | 0.258 | 14.62 | ||

| 205 | 5" | 5.563 | 5.295 | 10, 10S | 0.134 | 7.77 |

| 204 | 4.29 | XS, 80S | 0.355 | 17.61 | ||

| 203 | 4 1/2" | 5 | 4.506 | STD, 40S | 0.247 | 12.54 |

| 202 | 3.152 | XX | 0.674 | 27.54 | ||

| 201 | 3.438 | 160 | 0.531 | 22.51 | ||

| 200 | 3.624 | 120 | 0.438 | 19 | ||

| 199 | 3.826 | 80, XS, 80S | 0.337 | 14.98 | ||

| 198 | 4.026 | 40, STD, 40S | 0.237 | 10.79 | ||

| 197 | 4" | 4.5 | 4.26 | 10, 10S | 0.12 | 5.613 |

| 196 | 2.728 | XX | 0.636 | 22.85 | ||

| 195 | 3.364 | 80, XS, 80S | 0.318 | 12.51 | ||

| 194 | 3.548 | 40, STD, 40S | 0.226 | 9.109 | ||

| 193 | 3 1/2" | 4 | 3.76 | 10, 10S | 0.12 | 4.937 |

| 192 | 2.3 | XX | 0.6 | 18.58 | ||

| 191 | 2.624 | 160 | 0.438 | 14.32 | ||

| 190 | 2.9 | 80, XS, 80S | 0.3 | 10.25 | ||

| 189 | 3.068 | 40, STD, 40S | 0.216 | 7.576 | ||

| 188 | 3" | 3.5 | 3.26 | 10, 10S | 0.12 | 4.332 |

| 187 | 1.771 | XX | 0.552 | 13.7 | ||

| 186 | 2.125 | 160 | 0.375 | 10.01 | ||

| 185 | 2.323 | 80, XS, 80S | 0.276 | 7.651 | ||

| 184 | 2.469 | 40, STD, 40S | 0.203 | 5.793 | ||

| 183 | 2 1/2" | 2.875 | 2.635 | 10, 10S | 0.12 | 3.531 |

| 182 | 1.503 | XX | 0.436 | 9.029 | ||

| 181 | 1.689 | 160 | 0.344 | 7.462 | ||

| 180 | 1.939 | 80, XS, 80S | 0.218 | 5.022 | ||

| 179 | 2.067 | 40, STD, 40S | 0.154 | 3.853 | ||

| 178 | 2" | 2.375 | 2.157 | 10, 10S | 0.109 | 2.638 |

| 177 | 1.1 | XX | 0.4 | 6.408 | ||

| 176 | 1.337 | 160 | 0.281 | 4.859 | ||

| 175 | 1.5 | 80, XS, 80S | 0.2 | 3.631 | ||

| 174 | 1.61 | 40, STD, 40S | 0.145 | 2.718 | ||

| 173 | 1 1/2" | 1.9 | 1.682 | 10, 10S | 0.109 | 2.085 |

| 172 | 0.896 | XX | 0.382 | 5.214 | ||

| 171 | 1.16 | 160 | 0.25 | 3.765 | ||

| 170 | 1.278 | 80, XS, 80S | 0.191 | 2.997 | ||

| 169 | 1.38 | 40, STD, 40S | 0.14 | 2.273 | ||

| 168 | 1 1/4" | 1.66 | 1.442 | 10, 10S | 0.109 | 1.806 |

| 167 | 0.599 | XX | 0.358 | 3.659 | ||

| 166 | 0.815 | 160 | 0.25 | 2.844 | ||

| 165 | 0.957 | 80, XS, 80S | 0.179 | 2.172 | ||

| 164 | 1.049 | 40, STD, 40S | 0.133 | 1.679 | ||

| 163 | 1" | 1.315 | 1.097 | 10, 10S | 0.109 | 1.404 |

| 162 | 0.434 | XX | 0.308 | 2.441 | ||

| 161 | 0.614 | 160 | 0.218 | 1.937 | ||

| 160 | 0.742 | 80, XS, 80S | 0.154 | 1.474 | ||

| 159 | 0.824 | 40, STD, 40S | 0.113 | 1.131 | ||

| 158 | 3/4" | 1.05 | 0.884 | 10, 10S | 0.083 | 0.8572 |

| 157 | 0.252 | XX | 0.294 | 1.714 | ||

| 156 | 0.466 | 160 | 0.187 | 1.304 | ||

| 155 | 0.546 | 80, XS, 80S | 0.147 | 1.088 | ||

| 154 | 0.622 | 40, STD, 40S | 0.109 | 0.851 | ||

| 153 | 1/2" | 0.84 | 0.674 | 10, 10S | 0.083 | 0.671 |

| 152 | 0.423 | 80, XS, 80S | 0.126 | 0.7388 | ||

| 151 | 0.493 | 40, STD, 40S | 0.091 | 0.5676 | ||

| 150 | 3/8" | 0.675 | 0.545 | 10, 10S | 0.065 | 0.4235 |

| 149 | 0.302 | 80, XS, 80S | 0.119 | 0.5351 | ||

| 148 | 0.364 | 40, STD, 40S | 0.088 | 0.4248 | ||

| 147 | 1/4" | 0.54 | 0.41 | 10, 10S | 0.065 | 0.3297 |

| 146 | 0.215 | 80, XS, 80S | 0.095 | 0.3145 | ||

| 145 | 0.269 | 40, STD, 40S | 0.068 | 0.2447 | ||

| 144 | 1/8" | 0.405 | 0.307 | 10, 10S | 0.049 | 0.1863 |

| wdt_ID | NPS | OD | ID (in) | SCH | Wall | Est. lbs per ft |

|---|---|---|---|---|---|---|

| 243 | 11.75 | XS, 80S | 0.5 | 65.42 | ||

| 242 | 11.938 | 40 | 0.406 | 53.52 | ||

| 241 | 12 | STD, 40S | 0.375 | 49.56 | ||

| 240 | 12.09 | 30 | 0.33 | 43.77 | ||

| 239 | 12.25 | 20 | 0.25 | 33.38 | ||

| 238 | 12" | 12.75 | 12.39 | 10, 10S | 0.18 | 24.16 |

| 237 | 8.5 | 160 | 1.125 | 115.6 | ||

| 236 | 8.75 | 140, XX | 1 | 104.1 | ||

| 235 | 9.064 | 120 | 0.844 | 82.29 | ||

| 234 | 9.314 | 100 | 0.719 | 77.03 | ||

| 233 | 9.564 | 80 | 0.594 | 64.43 | ||

| 232 | 9.75 | 60, XS, 80S | 0.5 | 54.74 | ||

| 231 | 10.02 | 40, STD, 40S | 0.365 | 40.48 | ||

| 230 | 10.136 | 30 | 0.307 | 34.24 | ||

| 229 | 10.25 | 20 | 0.25 | 28.04 | ||

| 228 | 10" | 10.75 | 10.42 | 10, 10S | 0.165 | 18.65 |

| 227 | 6.875 | XX | 0.875 | 72.42 | ||

| 226 | 6.813 | 160 | 0.906 | 74.79 | ||

| 225 | 7.001 | 140 | 0.812 | 67.76 | ||

| 224 | 7.189 | 120 | 0.719 | 61.71 | ||

| 223 | 7.439 | 100 | 0.594 | 50.95 | ||

| 222 | 7.625 | 80, XS, 80S | 0.5 | 43.39 | ||

| 221 | 7.813 | 60 | 0.406 | 35.64 | ||

| 220 | 7.981 | 40, STD, 40S | 0.322 | 28.55 | ||

| 219 | 8.071 | 30 | 0.277 | 24.7 | ||

| 218 | 8.125 | 20 | 0.25 | 22.36 | ||

| 217 | 8" | 8.625 | 8.329 | 10, 10S | 0.148 | 13.4 |

| 216 | 4.897 | XX | 0.864 | 53.16 | ||

| 215 | 5.189 | 160 | 0.719 | 43.35 | ||

| 214 | 5.501 | 120 | 0.562 | 35.39 | ||

| 213 | 5.761 | 80, XS, 80S | 0.432 | 28.57 | ||

| 212 | 6.065 | 40, STD, 40S | 0.28 | 18.97 | ||

| 211 | 6" | 6.625 | 6.357 | 10, 10S | 0.134 | 9.29 |

| 210 | 4.063 | XX | 0.75 | 38.55 | ||

| 209 | 4.313 | 160 | 0.625 | 32.96 | ||

| 208 | 4.563 | 120 | 0.5 | 27.04 | ||

| 207 | 4.813 | 80, XS, 80S | 0.375 | 20.78 | ||

| 206 | 5.047 | 40, STD, 40S | 0.258 | 14.62 | ||

| 205 | 5" | 5.563 | 5.295 | 10, 10S | 0.134 | 7.77 |

| 204 | 4.29 | XS, 80S | 0.355 | 17.61 | ||

| 203 | 4 1/2" | 5 | 4.506 | STD, 40S | 0.247 | 12.54 |

| 202 | 3.152 | XX | 0.674 | 27.54 | ||

| 201 | 3.438 | 160 | 0.531 | 22.51 | ||

| 200 | 3.624 | 120 | 0.438 | 19 | ||

| 199 | 3.826 | 80, XS, 80S | 0.337 | 14.98 | ||

| 198 | 4.026 | 40, STD, 40S | 0.237 | 10.79 | ||

| 197 | 4" | 4.5 | 4.26 | 10, 10S | 0.12 | 5.613 |

| 196 | 2.728 | XX | 0.636 | 22.85 | ||

| 195 | 3.364 | 80, XS, 80S | 0.318 | 12.51 | ||

| 194 | 3.548 | 40, STD, 40S | 0.226 | 9.109 | ||

| 193 | 3 1/2" | 4 | 3.76 | 10, 10S | 0.12 | 4.937 |

| 192 | 2.3 | XX | 0.6 | 18.58 | ||

| 191 | 2.624 | 160 | 0.438 | 14.32 | ||

| 190 | 2.9 | 80, XS, 80S | 0.3 | 10.25 | ||

| 189 | 3.068 | 40, STD, 40S | 0.216 | 7.576 | ||

| 188 | 3" | 3.5 | 3.26 | 10, 10S | 0.12 | 4.332 |

| 187 | 1.771 | XX | 0.552 | 13.7 | ||

| 186 | 2.125 | 160 | 0.375 | 10.01 | ||

| 185 | 2.323 | 80, XS, 80S | 0.276 | 7.651 | ||

| 184 | 2.469 | 40, STD, 40S | 0.203 | 5.793 | ||

| 183 | 2 1/2" | 2.875 | 2.635 | 10, 10S | 0.12 | 3.531 |

| 182 | 1.503 | XX | 0.436 | 9.029 | ||

| 181 | 1.689 | 160 | 0.344 | 7.462 | ||

| 180 | 1.939 | 80, XS, 80S | 0.218 | 5.022 | ||

| 179 | 2.067 | 40, STD, 40S | 0.154 | 3.853 | ||

| 178 | 2" | 2.375 | 2.157 | 10, 10S | 0.109 | 2.638 |

| 177 | 1.1 | XX | 0.4 | 6.408 | ||

| 176 | 1.337 | 160 | 0.281 | 4.859 | ||

| 175 | 1.5 | 80, XS, 80S | 0.2 | 3.631 | ||

| 174 | 1.61 | 40, STD, 40S | 0.145 | 2.718 | ||

| 173 | 1 1/2" | 1.9 | 1.682 | 10, 10S | 0.109 | 2.085 |

| 172 | 0.896 | XX | 0.382 | 5.214 | ||

| 171 | 1.16 | 160 | 0.25 | 3.765 | ||

| 170 | 1.278 | 80, XS, 80S | 0.191 | 2.997 | ||

| 169 | 1.38 | 40, STD, 40S | 0.14 | 2.273 | ||

| 168 | 1 1/4" | 1.66 | 1.442 | 10, 10S | 0.109 | 1.806 |

| 167 | 0.599 | XX | 0.358 | 3.659 | ||

| 166 | 0.815 | 160 | 0.25 | 2.844 | ||

| 165 | 0.957 | 80, XS, 80S | 0.179 | 2.172 | ||

| 164 | 1.049 | 40, STD, 40S | 0.133 | 1.679 | ||

| 163 | 1" | 1.315 | 1.097 | 10, 10S | 0.109 | 1.404 |

| 162 | 0.434 | XX | 0.308 | 2.441 | ||

| 161 | 0.614 | 160 | 0.218 | 1.937 | ||

| 160 | 0.742 | 80, XS, 80S | 0.154 | 1.474 | ||

| 159 | 0.824 | 40, STD, 40S | 0.113 | 1.131 | ||

| 158 | 3/4" | 1.05 | 0.884 | 10, 10S | 0.083 | 0.8572 |

| 157 | 0.252 | XX | 0.294 | 1.714 | ||

| 156 | 0.466 | 160 | 0.187 | 1.304 | ||

| 155 | 0.546 | 80, XS, 80S | 0.147 | 1.088 | ||

| 154 | 0.622 | 40, STD, 40S | 0.109 | 0.851 | ||

| 153 | 1/2" | 0.84 | 0.674 | 10, 10S | 0.083 | 0.671 |

| 152 | 0.423 | 80, XS, 80S | 0.126 | 0.7388 | ||

| 151 | 0.493 | 40, STD, 40S | 0.091 | 0.5676 | ||

| 150 | 3/8" | 0.675 | 0.545 | 10, 10S | 0.065 | 0.4235 |

| 149 | 0.302 | 80, XS, 80S | 0.119 | 0.5351 | ||

| 148 | 0.364 | 40, STD, 40S | 0.088 | 0.4248 | ||

| 147 | 1/4" | 0.54 | 0.41 | 10, 10S | 0.065 | 0.3297 |

| 146 | 0.215 | 80, XS, 80S | 0.095 | 0.3145 | ||

| 145 | 0.269 | 40, STD, 40S | 0.068 | 0.2447 | ||

| 144 | 1/8" | 0.405 | 0.307 | 10, 10S | 0.049 | 0.1863 |

Pipe Schedule Discussion

Pipe schedule is the term the industry uses to describe the pipe’s thickness. ASME (American Society of Mechanical Engineers) has come up with the Schedule Number based on a modified version of Barlow’s wall thickness formula. It indicates the approximate value of the expression 1000 x P/S. The said formula is as follows:

Schedule Number = P/S

where P is the service pressure per square inch and S is the allowable stress per square inch

40 is probably the most well-known and most commonly used schedule. Schedule 40 is just a designator for pipe thickness. In layman’s term, schedule 40 pipe can handle a specific amount of pressure.

For instance, the schedule number of steel pipe that has an allowable stress of 10,000 psi for 350 psig of working pressure would be computed this way:

Schedule Number = (1,000)(350/10,000)

The schedule number would be 35 or approximately 40.

Pipe Schedule Chart Abbreviations:

- O.D. – Outer Diameter

- I.D. – Inner Diameter

- Est. LBS per Ft. – Estimate pounds per feet

- NPS – Nominal Pipe Size

- SCH – Schedule

- STD – Standard

- XS – Extra Strong

- XX – Double Extra Strong

Optimizing Your Pipeline Design with Comprehensive Line Pipe Specifications

When planning and implementing pipeline infrastructure for oil and gas transportation, the Line Pipe OD, ID, Weight and Schedule Chart provides essential reference data that helps engineers and procurement specialists make informed decisions based on specific flow requirements, pressure ratings, and installation parameters. Understanding the relationship between nominal pipe size, outside diameter, inside diameter, wall thickness, and weight is crucial for selecting the optimal pipe specifications for your specific application needs. At FlowTech Energy, we maintain an extensive inventory of line pipe across all standard dimensions and schedules, allowing operators to find the exact specifications required for both new installations and replacement projects.

Our experienced technical team can help you navigate the complexities of line pipe selection, ensuring you choose the right combination of dimensions and schedule for your specific pipeline application. We understand that proper specification is critical not only for immediate compatibility with existing infrastructure but also for long-term operational performance and pressure handling capabilities. Contact us today at 1-877-645-6693 to discuss how our inventory of quality line pipe can provide the perfect balance of dimensional accuracy, pressure resistance, and structural durability for your next pipeline project. Whether you’re working with standard applications or specialized high-pressure environments, our comprehensive selection of API-compliant line pipe ensures you’ll find the exact specifications needed to optimize flow capacity, pressure handling, and overall system integrity throughout your pipeline’s operational lifecycle.

Go here if you are looking for the Line Pipe Schedule and Thickness Chart