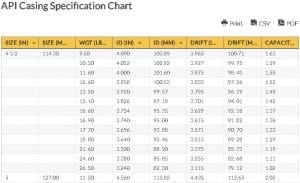

API Casing Specification Chart

The API Casing Specification Chart provides specific data that is essential before any operation begins. It includes different casing sizes and capacities that would define a casing’s limitations. Casings are also known as Encasement pipe, which comprises steel tubes that are utilized for gas and oil underground operations. It protects a utility system from detrimental factors.

The API Casing Specification Chart provides specific data that is essential before any operation begins. It includes different casing sizes and capacities that would define a casing’s limitations. Casings are also known as Encasement pipe, which comprises steel tubes that are utilized for gas and oil underground operations. It protects a utility system from detrimental factors.

API Casing Specification Discussion

Pipe casing plays a huge role in underground operations and is also considered an important material in wells. Another function of the casing is to keep the stability of a borehole, control the pressure during the entire process, and prevent the contamination of water sands.

Listed are the types of pipe casing used in the industry:

Conductor Casing

This casing must be installed before the drilling rig. This is usually placed through a drill with a small auger. Its length is not more than 50 feet.

Surface Casing

This extends up to 2,000 feet long and has a smaller diameter compared to conductor casing. Its function is to keep the water deposits from being contaminated by the presence of salt water or hydrocarbons below the surface.

Intermediate Casing

This is where the longest section is found in a well. Similar to other kinds of casing, it protects the well from any harmful factors–for instance, underground shale, contaminating elements, below-the-ground pressure zones, and salt water deposits.

Liner

This is commonly preferred over intermediate casing. It runs a casing bottom through an open well area.

Production casing

This casing is found in the deepest section and is installed last. Its size usually depends on many factors, such as the possibility of deepening the well in the future and the equipment utilized during the process.

Aside from these, the pipe casings are made from different grades, which affect their efficiency and durability.

| Grade | Yield Strength | Min. Tensile Strength | API Color Code | |

|---|---|---|---|---|

| wdt_ID | Grade | Yield Strength | Min. Tensile Strength | API Color Code |

| 1 | J55 | 379-552 MPa (55-80 ksi) | 517 MPa (75 ksi) | 1 bright green band |

| 2 | K55 | 379-552 MPa (55-80 ksi) | 665 MPa (95 ksi) | 2 bright green bands |

| 3 | N80 | 552-758 MPa (55-80 ksi) | 689 MPa (100 ksi) | 1 red (N80-1), 1 red band + 1 bright green band (N80-Q) |

| 4 | L80 | 552-665 MPa (80-95 ksi) | 655 MPa (95 ksi) | 1 red + 1 brown (L80), 1 red + 1 brown + 2 yellow (L80 9Cr), 1 red + 1 brown + 1 yellow (L80 13Cr) |

| 5 | P110 | 758-965 MPa (110-140 ksi) | 862 MPa (125 ksi) | 1 white band |

API Casing Specification Chart

| wdt_ID | Size (in) | Size (mm) | Wgt (lb/ft) | ID (in) | ID (mm) | Drift (in) | Drift (mm) | Capacity (bbl/100ft) |

|---|---|---|---|---|---|---|---|---|

| 1 | 4 1/2 | 114.30 | 9.50 | 4.090 | 103.89 | 3.965 | 100.71 | 1.63 |

| 2 | 10. 50 | 4.052 | 102.92 | 3.927 | 99. 75 | 1.59 | ||

| 4 | 11. 60 | 4.000 | 101.60 | 3.875 | 98. 43 | 1.55 | ||

| 5 | 12. 60 | 3.958 | 100.53 | 3.833 | 97. 36 | 1.52 | ||

| 6 | 13. 50 | 3.920 | 99. 57 | 3.795 | 96. 39 | 1.49 | ||

| 7 | 15. 10 | 3.826 | 97. 18 | 3.701 | 94. 01 | 1.42 | ||

| 8 | 16. 60 | 3.754 | 95. 35 | 3.629 | 92. 18 | 1.37 | ||

| 9 | 16. 90 | 3.740 | 95. 00 | 3.615 | 91. 82 | 1.36 | ||

| 10 | 17. 70 | 3.696 | 93. 88 | 3.571 | 90. 70 | 1.33 | ||

| 11 | 18. 80 | 3.640 | 92. 46 | 3.515 | 89. 28 | 1.29 | ||

| 12 | 21. 60 | 3.500 | 88. 90 | 3.375 | 85. 73 | 1.19 | ||

| 13 | 24. 60 | 3.380 | 85. 85 | 3.255 | 82. 68 | 1.11 | ||

| 14 | 26. 50 | 3.240 | 82. 30 | 3.115 | 79. 12 | 1.02 | ||

| 15 | 5 | 127.00 | 11. 50 | 4.560 | 115.82 | 4.435 | 112.65 | 2.02 |

| 16 | 13. 00 | 4.494 | 114.15 | 4.369 | 110.97 | 1.96 | ||

| 17 | 15. 00 | 4.408 | 111.96 | 4.283 | 108.79 | 1.89 | ||

| 18 | 18. 00 | 4.276 | 108.61 | 4.151 | 105.44 | 1.78 | ||

| 19 | 20. 30 | 4.184 | 106.27 | 4.059 | 103.10 | 1.70 | ||

| 20 | 20. 80 | 4.156 | 105.56 | 4.031 | 102.39 | 1.68 | ||

| 21 | 21. 40 | 4.126 | 104.80 | 4.001 | 101.63 | 1.65 | ||

| 22 | 23. 20 | 4.044 | 102.72 | 3.919 | 99. 54 | 1.59 | ||

| 23 | 24. 20 | 4.000 | 101.60 | 3.875 | 98. 43 | 1.55 | ||

| 24 | 26. 70 | 3.876 | 98. 45 | 3.751 | 95. 28 | 1.46 | ||

| 25 | 32. 00 | 3.620 | 91. 95 | 3.495 | 88. 77 | 1.27 | ||

| 26 | 5 1/2 | 139.70 | 13. 00 | 5.044 | 128.12 | 4.919 | 124.94 | 2.47 |

| 27 | 14. 00 | 5.012 | 127.30 | 4.887 | 124.13 | 2.44 | ||

| 28 | 15. 50 | 4.950 | 125.73 | 4.825 | 122.56 | 2.38 | ||

| 29 | 17. 00 | 4.892 | 124.26 | 4.767 | 121.08 | 2.32 | ||

| 30 | 20. 00 | 4.778 | 121.36 | 4.653 | 118.19 | 2.22 | ||

| 31 | 23. 00 | 4.670 | 118.62 | 4.545 | 115.44 | 2.12 | ||

| 32 | 26. 00 | 4.548 | 115.52 | 4.423 | 112.34 | 2.01 | ||

| 33 | 28. 40 | 4.440 | 112.78 | 4.315 | 109.60 | 1.91 | ||

| 34 | 29. 70 | 4.376 | 111.15 | 4.251 | 107.98 | 1.86 | ||

| 35 | 32. 30 | 4.276 | 108.61 | 4.151 | 105.44 | 1.78 | ||

| 36 | 36. 40 | 4.090 | 103.89 | 3.965 | 100.71 | 1.62 | ||

| 37 | 39. 30 | 4.044 | 102.72 | 3.919 | 79. 54 | 1.59 | ||

| 38 | 6 | 152.40 | 15. 00 | 5.542 | 140.77 | 5.399 | 137.13 | 2.98 |

| 39 | 18. 00 | 5.424 | 137.77 | 5.299 | 134.59 | 2.86 | ||

| 40 | 20. 00 | 5.352 | 135.94 | 5.227 | 132.77 | 2.78 | ||

| 41 | 23. 00 | 5.240 | 133.10 | 5.115 | 129.92 | 2.67 | ||

| 42 | 26. 00 | 5.132 | 130.35 | 5.007 | 127.18 | 2.56 | ||

| 43 | 6 5/8 | 168.28 | 17. 00 | 6.135 | 155.83 | 6.010 | 152.65 | 3.66 |

| 44 | 20. 00 | 6.049 | 153.64 | 5.924 | 150.47 | 3.55 | ||

| 45 | 24. 00 | 5.921 | 150.39 | 5.796 | 147.22 | 3.41 | ||

| 46 | 28. 00 | 5.791 | 147.09 | 5.666 | 143.92 | 3.26 | ||

| 47 | 32. 00 | 5.675 | 144.15 | 5.550 | 140.97 | 3.13 | ||

| 48 | 35. 00 | 5.575 | 141.61 | 5.450 | 138.43 | 3.02 | ||

| 49 | 43. 20 | 5.375 | 136.53 | 5.250 | 133.35 | 2.81 | ||

| 50 | 69. 63 | 4.375 | 111.13 | 4.250 | 107.95 | 1.86 | ||

| 51 | 7 | 177.80 | 17. 00 | 6.538 | 166.07 | 6.413 | 162.89 | 4.15 |

API Casing Specification Chart

| wdt_ID | Size (in) | Size (mm) | Wgt (lb/ft) | ID (in) | ID (mm) | Drift (in) | Drift (mm) | Capacity (bbl/100ft) |

|---|---|---|---|---|---|---|---|---|

| 1 | 4 1/2 | 114.30 | 9.50 | 4.090 | 103.89 | 3.965 | 100.71 | 1.63 |

| 2 | 10. 50 | 4.052 | 102.92 | 3.927 | 99. 75 | 1.59 | ||

| 4 | 11. 60 | 4.000 | 101.60 | 3.875 | 98. 43 | 1.55 | ||

| 5 | 12. 60 | 3.958 | 100.53 | 3.833 | 97. 36 | 1.52 | ||

| 6 | 13. 50 | 3.920 | 99. 57 | 3.795 | 96. 39 | 1.49 | ||

| 7 | 15. 10 | 3.826 | 97. 18 | 3.701 | 94. 01 | 1.42 | ||

| 8 | 16. 60 | 3.754 | 95. 35 | 3.629 | 92. 18 | 1.37 | ||

| 9 | 16. 90 | 3.740 | 95. 00 | 3.615 | 91. 82 | 1.36 | ||

| 10 | 17. 70 | 3.696 | 93. 88 | 3.571 | 90. 70 | 1.33 | ||

| 11 | 18. 80 | 3.640 | 92. 46 | 3.515 | 89. 28 | 1.29 | ||

| 12 | 21. 60 | 3.500 | 88. 90 | 3.375 | 85. 73 | 1.19 | ||

| 13 | 24. 60 | 3.380 | 85. 85 | 3.255 | 82. 68 | 1.11 | ||

| 14 | 26. 50 | 3.240 | 82. 30 | 3.115 | 79. 12 | 1.02 | ||

| 15 | 5 | 127.00 | 11. 50 | 4.560 | 115.82 | 4.435 | 112.65 | 2.02 |

| 16 | 13. 00 | 4.494 | 114.15 | 4.369 | 110.97 | 1.96 | ||

| 17 | 15. 00 | 4.408 | 111.96 | 4.283 | 108.79 | 1.89 | ||

| 18 | 18. 00 | 4.276 | 108.61 | 4.151 | 105.44 | 1.78 | ||

| 19 | 20. 30 | 4.184 | 106.27 | 4.059 | 103.10 | 1.70 | ||

| 20 | 20. 80 | 4.156 | 105.56 | 4.031 | 102.39 | 1.68 | ||

| 21 | 21. 40 | 4.126 | 104.80 | 4.001 | 101.63 | 1.65 | ||

| 22 | 23. 20 | 4.044 | 102.72 | 3.919 | 99. 54 | 1.59 | ||

| 23 | 24. 20 | 4.000 | 101.60 | 3.875 | 98. 43 | 1.55 | ||

| 24 | 26. 70 | 3.876 | 98. 45 | 3.751 | 95. 28 | 1.46 | ||

| 25 | 32. 00 | 3.620 | 91. 95 | 3.495 | 88. 77 | 1.27 | ||

| 26 | 5 1/2 | 139.70 | 13. 00 | 5.044 | 128.12 | 4.919 | 124.94 | 2.47 |

| 27 | 14. 00 | 5.012 | 127.30 | 4.887 | 124.13 | 2.44 | ||

| 28 | 15. 50 | 4.950 | 125.73 | 4.825 | 122.56 | 2.38 | ||

| 29 | 17. 00 | 4.892 | 124.26 | 4.767 | 121.08 | 2.32 | ||

| 30 | 20. 00 | 4.778 | 121.36 | 4.653 | 118.19 | 2.22 | ||

| 31 | 23. 00 | 4.670 | 118.62 | 4.545 | 115.44 | 2.12 | ||

| 32 | 26. 00 | 4.548 | 115.52 | 4.423 | 112.34 | 2.01 | ||

| 33 | 28. 40 | 4.440 | 112.78 | 4.315 | 109.60 | 1.91 | ||

| 34 | 29. 70 | 4.376 | 111.15 | 4.251 | 107.98 | 1.86 | ||

| 35 | 32. 30 | 4.276 | 108.61 | 4.151 | 105.44 | 1.78 | ||

| 36 | 36. 40 | 4.090 | 103.89 | 3.965 | 100.71 | 1.62 | ||

| 37 | 39. 30 | 4.044 | 102.72 | 3.919 | 79. 54 | 1.59 | ||

| 38 | 6 | 152.40 | 15. 00 | 5.542 | 140.77 | 5.399 | 137.13 | 2.98 |

| 39 | 18. 00 | 5.424 | 137.77 | 5.299 | 134.59 | 2.86 | ||

| 40 | 20. 00 | 5.352 | 135.94 | 5.227 | 132.77 | 2.78 | ||

| 41 | 23. 00 | 5.240 | 133.10 | 5.115 | 129.92 | 2.67 | ||

| 42 | 26. 00 | 5.132 | 130.35 | 5.007 | 127.18 | 2.56 | ||

| 43 | 6 5/8 | 168.28 | 17. 00 | 6.135 | 155.83 | 6.010 | 152.65 | 3.66 |

| 44 | 20. 00 | 6.049 | 153.64 | 5.924 | 150.47 | 3.55 | ||

| 45 | 24. 00 | 5.921 | 150.39 | 5.796 | 147.22 | 3.41 | ||

| 46 | 28. 00 | 5.791 | 147.09 | 5.666 | 143.92 | 3.26 | ||

| 47 | 32. 00 | 5.675 | 144.15 | 5.550 | 140.97 | 3.13 | ||

| 48 | 35. 00 | 5.575 | 141.61 | 5.450 | 138.43 | 3.02 | ||

| 49 | 43. 20 | 5.375 | 136.53 | 5.250 | 133.35 | 2.81 | ||

| 50 | 69. 63 | 4.375 | 111.13 | 4.250 | 107.95 | 1.86 | ||

| 51 | 7 | 177.80 | 17. 00 | 6.538 | 166.07 | 6.413 | 162.89 | 4.15 |

API Casing Chart Abbreviations:

- I.D. – Inside Diameter

- in – inch

- mm – millimeter

- lbs/ft – pounds per feet

- bbl/100ft – barrel per 100 feet

API Casing Specification

Casings are specified by their size, weight, and grade.

- Nominal weight refers to the tubing’s linear weight. It also defines its wall thickness

- ID refers to the inner diameter

- The drift diameter is commonly 1/8 (3.2mm) and less than ID

- Yield Strength is expressed in ksi (kilograms per square inch) or MPa -megapascals

1MPa= 1,000,000 pascals (a unit used to describe pressure ranges in hydraulic systems)

Go here if you are looking for the Casing Nipple Chart.