Drill Collar Weight and Bending Strength Chart

In the oil production process, line pipe is not the only tool needed for a successful wellbore. Among the materials used alongside line pipe are drill collars.

Drill collars are used to provide weight on the drill bit. They are tubular pieces of a drill string, which have thick walls made of steel or special kinds of alloy. Another main function of drill collars is to provide a path for the drilling fluid that is being pumped through them.

Drill Collar Dynamics

A drill collar works because of the gravity that acts on it. Because of its large mass, gravity pulls down the collars and provides the downward force that drill bits need to break through the ground.

Multiple collars can also be assembled together to make up what is called the bottom hole assembly. During the drilling process, the downward force provided by drill collars is built up by lowering the drill bit until it touches the bottom so that more weight is also applied to such a drill bit.

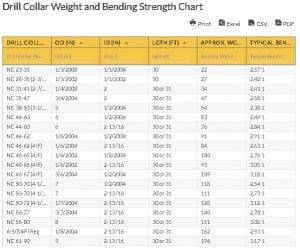

Given how these drill collars work, it is of vital importance that their material provides the weight and bending strength necessary for their function. Such is shown in the Drill Collar Weight and Bending Strength Chart below.

Drill Collar Weight and Bending Strength Chart

| Drill Collar Number | OD (in) | ID (in) | Lgth (ft) | Approx. Wgt (lb/ft) | Typical Bending Strength Ratio | |

|---|---|---|---|---|---|---|

| wdt_ID | Drill Collar Number | OD (in) | ID (in) | Lgth (ft) | Approx. Wgt (lb/ft) | Typical Bending Strength Ratio |

| 1 | NC 23-31 | 1/3/2008 | 1/1/2004 | 30 | 22 | 2.57:1 |

| 2 | NC 26-35 (2-3/8 IF) | 1/3/2002 | 1/1/2002 | 30 | 27 | 2.42:1 |

| 3 | NC 31-41 (2-7/8 IF) | 1/4/2008 | 2 | 30 or 31 | 34 | 2.43:1 |

| 4 | NC 35-47 | 3/4/2004 | 2 | 30 or 31 | 47 | 2.58:1 |

| 5 | NC 38-50 (3-1/2 IF) | 5 | 1/2/2004 | 30 or 31 | 54 | 2.38:1 |

| 6 | NC 44-60 | 6 | 1/2/2004 | 30 or 31 | 83 | 2.49:1 |

| 7 | NC 44-60 | 6 | 2-13 /16 | 30 or 31 | 76 | 2.84:1 |

| 8 | NC 44-62 | 1/6/2004 | 1/2/2004 | 30 or 31 | 91 | 2.91:1 |

| 9 | NC 46-62 (4 IF) | 1/6/2004 | 2-13 /16 | 30 or 31 | 84 | 2.63:1 |

| 10 | NC 46-65 (4 IF) | 1/6/2002 | 1/2/2004 | 30 or 31 | 100 | 2.76:1 |

| 11 | NC 46-65 (4 IF) | 1/6/2002 | 2-13 /16 | 30 or 31 | 93 | 3.05:1 |

| 12 | NC 46-67 (4 IF) | 3/6/2004 | 1/2/2004 | 30 or 31 | 109 | 3.18:1 |

| 13 | NC 50-70 (4-1/2 IF) | 7 | 1/2/2004 | 30 or 31 | 118 | 2.54:1 |

| 14 | NC 50-70 (4-1/2 IF) | 7 | 2-13 /16 | 30 or 31 | 111 | 2.73:1 |

| 15 | NC 50-72 (4-1/2 IF) | 1/7/2004 | 2-13 /16 | 30 or 31 | 120 | 3.12:1 |

| 16 | NC 56-77 | 3/7/2004 | 2-13 /16 | 30 or 31 | 140 | 2.70:1 |

| 17 | NC 56-80 | 8 | 2-13 /16 | 30 or 31 | 151 | 3.02:1 |

| 18 | 6-5/8 API Reg | 1/8/2004 | 2-13 /16 | 30 or 31 | 162 | 2.93:1 |

| 19 | NC 61-90 | 9 | 2-13 /16 | 30 or 31 | 196 | 3.17:1 |

| 20 | 7-5/8 API Reg | 1/9/2002 | 3 | 30 or 31 | 217 | 2.81:1 |

| 21 | NC 70-97 | 3/9/2004 | 3 | 30 or 31 | 230 | 2.57:1 |

| 22 | NC 70-100 | 10 | 3 | 30 or 31 | 243 | 2.81:1 |

| 23 | 8-5/8 API Reg | 11 | 3 | 30 or 31 | 300 | 2.84:1 |

Drill Collar Weight and Bending Strength Chart

| Drill Collar Number | OD (in) | ID (in) | Lgth (ft) | Approx. Wgt (lb/ft) | Typical Bending Strength Ratio | |

|---|---|---|---|---|---|---|

| wdt_ID | Drill Collar Number | OD (in) | ID (in) | Lgth (ft) | Approx. Wgt (lb/ft) | Typical Bending Strength Ratio |

| 1 | NC 23-31 | 1/3/2008 | 1/1/2004 | 30 | 22 | 2.57:1 |

| 2 | NC 26-35 (2-3/8 IF) | 1/3/2002 | 1/1/2002 | 30 | 27 | 2.42:1 |

| 3 | NC 31-41 (2-7/8 IF) | 1/4/2008 | 2 | 30 or 31 | 34 | 2.43:1 |

| 4 | NC 35-47 | 3/4/2004 | 2 | 30 or 31 | 47 | 2.58:1 |

| 5 | NC 38-50 (3-1/2 IF) | 5 | 1/2/2004 | 30 or 31 | 54 | 2.38:1 |

| 6 | NC 44-60 | 6 | 1/2/2004 | 30 or 31 | 83 | 2.49:1 |

| 7 | NC 44-60 | 6 | 2-13 /16 | 30 or 31 | 76 | 2.84:1 |

| 8 | NC 44-62 | 1/6/2004 | 1/2/2004 | 30 or 31 | 91 | 2.91:1 |

| 9 | NC 46-62 (4 IF) | 1/6/2004 | 2-13 /16 | 30 or 31 | 84 | 2.63:1 |

| 10 | NC 46-65 (4 IF) | 1/6/2002 | 1/2/2004 | 30 or 31 | 100 | 2.76:1 |

| 11 | NC 46-65 (4 IF) | 1/6/2002 | 2-13 /16 | 30 or 31 | 93 | 3.05:1 |

| 12 | NC 46-67 (4 IF) | 3/6/2004 | 1/2/2004 | 30 or 31 | 109 | 3.18:1 |

| 13 | NC 50-70 (4-1/2 IF) | 7 | 1/2/2004 | 30 or 31 | 118 | 2.54:1 |

| 14 | NC 50-70 (4-1/2 IF) | 7 | 2-13 /16 | 30 or 31 | 111 | 2.73:1 |

| 15 | NC 50-72 (4-1/2 IF) | 1/7/2004 | 2-13 /16 | 30 or 31 | 120 | 3.12:1 |

| 16 | NC 56-77 | 3/7/2004 | 2-13 /16 | 30 or 31 | 140 | 2.70:1 |

| 17 | NC 56-80 | 8 | 2-13 /16 | 30 or 31 | 151 | 3.02:1 |

| 18 | 6-5/8 API Reg | 1/8/2004 | 2-13 /16 | 30 or 31 | 162 | 2.93:1 |

| 19 | NC 61-90 | 9 | 2-13 /16 | 30 or 31 | 196 | 3.17:1 |

| 20 | 7-5/8 API Reg | 1/9/2002 | 3 | 30 or 31 | 217 | 2.81:1 |

| 21 | NC 70-97 | 3/9/2004 | 3 | 30 or 31 | 230 | 2.57:1 |

| 22 | NC 70-100 | 10 | 3 | 30 or 31 | 243 | 2.81:1 |

| 23 | 8-5/8 API Reg | 11 | 3 | 30 or 31 | 300 | 2.84:1 |

Drill Collar Weight and Bending Strength Chart Terms

In the Drill Collar Weight and Bending Strength Chart, the following key terms are listed: (1) drill collar number, (2) outside diameter measured in inches, (3) inside diameter measured in inches, (4) length in feet, (5) approximate weight in pounds per feet), and (6) typical bending strength ratio.

The drill collar number is used as the main specification of the drill collar. Additional notes about this are also seen at the bottom of the table. The outside diameter and inside diameter, both measured in inches, are what describe the size of the drill collar.

Aside from the circular dimensions of the collar, the length and approximate weight of the drill collar is also given in the table.

The Drill Collar Weight and Bending Strength Chart shows the typical bending strength ratio. This piece of information is important because many failures in drill collar connections are a result of not being able to take into consideration the bending strength ratio. This ratio describes the relative stiffness in the drilling structure and the behavior of a connection in a “rotational cyclical environment”.

Drill Collar Weight and Bending Strength Chart Abbreviations:

- I.D – Inside diameter

- O.D – Outside diameter

- Lgth – Length

- Lb/ft – Pound per foot

- in. – inch

Go here if you are looking for the Drill Collar Capacity and Displacement Chart.