Drill Pipe Heavy Weight Chart

Drill pipe heavy weight is a type of drill pipe with thickened walls and longer collars compared to the standard drill pipe. This provides the heavy weight drill pipe (HWDP) with higher tensile strength. To facilitate greater support, HDWP is positioned near the topmost part of a long drill string.

Drill Pipe Heavy Weight Specifications

Drill pipe heavy weight usually functions as a transitional part from a heavy drill collar to comparatively lightweight drill pipe. The wall of an intermediate HDWP measures about one-inch-thick, beneficial in the inhibition of stress concentration at the upper portion of drill collars. Higher RPM drilling with lessened torque and differential pressure sticking is possible with the use of heavy weight drill pipe.

A wear pad or unique middle upset can be seen in HDWP, allowing the tube to stay away from the hole wall, resulting in the decrease in hole drag and differential sticking glitches.

Drill Pipe Heavy Weight Benefits

Directional drilling is best applied with a heavy weight drill pipe. Directional control is made easy with reduced connection fatigue issues generic to horizontal or high-angle drilling, all credits to the ability of HWDP to bend easily.

Highly sturdy heavy weight drill pipe is commonly utilized in the hole of extended reach and horizontal well to pull on the bit, more particularly in wells where there is a low ratio between the measured depth ratio and the total vertical depth.

Different combinations of drill pipe with heavy weight, drill collars, and conventional drill string gear can be established to keep up with the intensity of the drilling conditions.

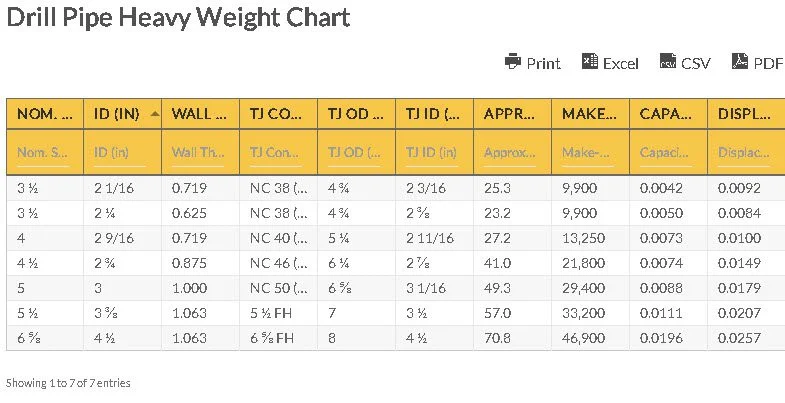

Drill Pipe Heavy Weight Chart

| wdt_ID | Nom. Size (in) | ID (in) | Wall Thkns (in) | TJ Conn Size (in) | TJ OD (in) | TJ ID (in) | Approx. Wgt Tube & Jts (lb/ft) | Make-up Torq (ft-lb) | Capacity (bbl/ft) | Displacement (bbl/ft) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 3 ½ | 2 1/16 | 0.719 | NC 38 (3 ½ IF) | 4 ¾ | 2 3/16 | 25.3 | 9,900 | 0.0042 | 0.0092 |

| 2 | 3 ½ | 2 ¼ | 0.625 | NC 38 (3 ½ IF) | 4 ¾ | 2 ⅜ | 23.2 | 9,900 | 0.0050 | 0.0084 |

| 3 | 4 | 2 9/16 | 0.719 | NC 40 (4 FH) | 5 ¼ | 2 11/16 | 27.2 | 13,250 | 0.0073 | 0.0100 |

| 4 | 4 ½ | 2 ¾ | 0.875 | NC 46 (4 IF) | 6 ¼ | 2 ⅞ | 41.0 | 21,800 | 0.0074 | 0.0149 |

| 5 | 5 | 3 | 1.000 | NC 50 (4 ½ IF) | 6 ⅝ | 3 1/16 | 49.3 | 29,400 | 0.0088 | 0.0179 |

| 6 | 5 ½ | 3 ⅜ | 1.063 | 5 ½ FH | 7 | 3 ½ | 57.0 | 33,200 | 0.0111 | 0.0207 |

| 7 | 6 ⅝ | 4 ½ | 1.063 | 6 ⅝ FH | 8 | 4 ½ | 70.8 | 46,900 | 0.0196 | 0.0257 |

Drill Pipe Heavy Weight Chart

| wdt_ID | Nom. Size (in) | ID (in) | Wall Thkns (in) | TJ Conn Size (in) | TJ OD (in) | TJ ID (in) | Approx. Wgt Tube & Jts (lb/ft) | Make-up Torq (ft-lb) | Capacity (bbl/ft) | Displacement (bbl/ft) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 3 ½ | 2 1/16 | 0.719 | NC 38 (3 ½ IF) | 4 ¾ | 2 3/16 | 25.3 | 9,900 | 0.0042 | 0.0092 |

| 2 | 3 ½ | 2 ¼ | 0.625 | NC 38 (3 ½ IF) | 4 ¾ | 2 ⅜ | 23.2 | 9,900 | 0.0050 | 0.0084 |

| 3 | 4 | 2 9/16 | 0.719 | NC 40 (4 FH) | 5 ¼ | 2 11/16 | 27.2 | 13,250 | 0.0073 | 0.0100 |

| 4 | 4 ½ | 2 ¾ | 0.875 | NC 46 (4 IF) | 6 ¼ | 2 ⅞ | 41.0 | 21,800 | 0.0074 | 0.0149 |

| 5 | 5 | 3 | 1.000 | NC 50 (4 ½ IF) | 6 ⅝ | 3 1/16 | 49.3 | 29,400 | 0.0088 | 0.0179 |

| 6 | 5 ½ | 3 ⅜ | 1.063 | 5 ½ FH | 7 | 3 ½ | 57.0 | 33,200 | 0.0111 | 0.0207 |

| 7 | 6 ⅝ | 4 ½ | 1.063 | 6 ⅝ FH | 8 | 4 ½ | 70.8 | 46,900 | 0.0196 | 0.0257 |

Drill Pipe Heavy Weight – Terms and Definitions

A Heavy weight drill pipe is the oil and gas industry’s choice for operations of intermediate weight drill stem. It has different dimensions following the requirements set, similar with the standard drill pipe.

- Nominal Size – The nominal size of HWDP is about the same as the inside diameter of those with less than 14” actual inside diameter measurement and is equal to the outside diameter of those with larger than 14”.

- Nominal Tube Dimensions – This is composed of the inside diameter (ID) and wall thickness, which are two of the three dimensions of a round tube section.

- Tool Joint – Tool joint refers to the connection within the piping system. It is the location of pipe connections, valves, and fittings.

- Make-up Torque – This refers to the movement required to facilitate pipe rotation.

- Capacity – It is the volume of fluid that can be enclosed within the pipe.

- Displacement – The volume of fluid to be displaced–if positioned into fluid open ended–in order to be filled inside is the displacement for open-ended HWDP pipe.

The volume of fluid to be displaced if positioned into fluid having the lower portion closed–to prevent fluid from going inside–is the displacement for closed-ended pipe.

Drill Pipe Heavy Weight Chart Abbreviations:

- ID – Inside Diameter

- OD – Outside Diameter

- in -inch

- lb/ft – pound per foot

- bbl/ft – barrel per feet

- Jts – joints

- Torq – Torque

- Nom.Size – Nominal Size

- Wall Thkns – Wall Thickness

- TJ Conn Size – Tool Joint Connection Size

Sourcing Heavy Weight Drill Pipe for Demanding Drilling Applications

Selecting the appropriate heavy weight drill pipe (HWDP) specifications is essential for successful directional drilling, extended reach wells, and horizontal drilling operations where standard drill pipe lacks sufficient weight and fatigue resistance. The charts above provide comprehensive specifications for HWDP including nominal size, wall thickness, tool joint dimensions, makeup torque requirements, capacity, and displacement values that drilling engineers use to design drill string assemblies optimized for specific wellbore trajectories and drilling conditions. HWDP serves as the critical transition section between heavy drill collars at the bottom of the string and lighter conventional drill pipe above, providing additional weight on bit while reducing stress concentration and connection fatigue that can lead to costly drill string failures in high-angle and horizontal wells. Understanding the relationship between HWDP dimensions, tensile strength ratings, and bending characteristics ensures proper drill string design that delivers adequate weight transfer to the bit while maintaining structural integrity under the cyclic loading, torque, and bending stresses encountered in complex wellbore geometries.

Flowtech Energy maintains inventory of API-certified heavy weight drill pipe in standard sizes from 3-1/2 inch through 5-1/2 inch with various wall thicknesses and premium tool joint connections suited for demanding drilling environments. Our HWDP inventory includes both new premium pipe and thoroughly inspected used pipe that has been evaluated for remaining wall thickness, connection wear, and serviceability according to API RP 7G inspection standards. Each HWDP section is supplied with dimensional specifications, material certifications, and inspection reports documenting tube condition, tool joint integrity, and makeup torque requirements to ensure reliable performance in your drilling operations. We understand that HWDP represents a significant capital investment in drill string assemblies, and our technical team provides engineering support to help optimize drill string design, evaluate used HWDP for cost-effective alternatives to new pipe, and coordinate delivery schedules that support your drilling program timeline. Whether you’re drilling extended reach wells in offshore environments, horizontal wells in unconventional shale plays, or directional wells requiring precise wellbore placement, we deliver expert guidance on HWDP selection, procurement strategies that balance performance and economics, and logistics support for domestic and international drilling operations. If you need assistance selecting appropriate HWDP specifications for your drill string design, sourcing certified pipe with complete inspection documentation, or coordinating delivery and field support for drilling operations, contact Flowtech Energy at 1-877-645-6693. We provide comprehensive drill pipe procurement solutions—ensuring your drilling operations have the right equipment to achieve wellbore objectives safely, efficiently, and economically while minimizing non-productive time and maximizing drill string reliability in challenging drilling environments.

Go here if you are looking for the Drill Pipe Specification with Upset and Tool Joint Chart.