Line Pipe Schedule 120 Dimension, Weight and Thickness Chart

Line Pipe Schedule

The term “schedule” in Line Pipe Schedule 120 Dimension, Thickness, and Weight refers to the wall thickness of the pipe used in the oil and gas industry.

As the wall thickness increases, the schedule number rises. Higher schedule pipe such as 100 and 120 have the same exterior diameter as 40, 6, and others. However, the higher schedules 100 and 120 have extra thickness in their interiors.

The American Society of Mechanical Engineers (ASME) committee developed the standard pipe schedules to save cost. The most popular schedule is 30, while the least used are 5, 60, 100, 120, and 140.

The pipe schedule has the following approximate value:

Schedule Number = (1,000) (P/S)

For instance:

P = PSI or internal working pressure

S = allowed stress or PSI of the construction material

To determine the pipe schedule:

Inside Diameter / Wall Thickness

The pipe schedule 120 is a thickness designator that means schedule 120 is thicker than schedule 100. An increase in service pressure can increase the pipe’s schedule.

Relationship among Dimensional Values

The increase in nominal size also increases the outside diameter (mm), wall thickness (mm), and weight (lb/ft) or (kg/m), except for the outside diameter (inches) that stays the same.

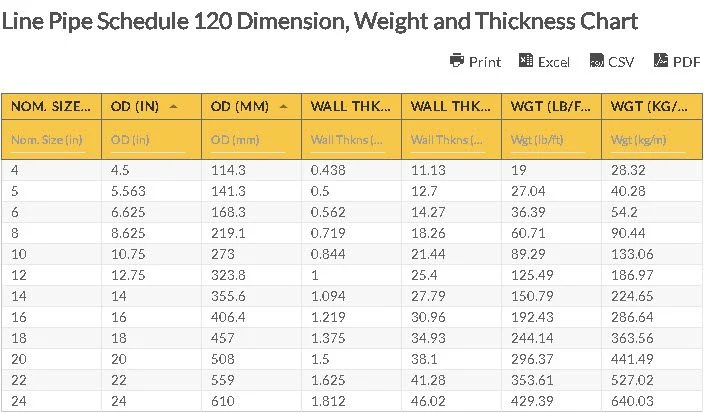

Line Pipe Schedule 120 Dimension, Weight and Thickness Chart

The table for Line Pipe Schedule 120 Dimension, Thickness and Weight is useful for determining the exact numerical measures or dimensions such as the nominal size, outside diameter, wall thickness, and weight of the Pipe Schedule 120.

| wdt_ID | Nom. Size (in) | OD (in) | OD (mm) | Wall Thkns (in) | Wall Thkns (mm) | Wgt (lb/ft) | Wgt (kg/m) |

|---|---|---|---|---|---|---|---|

| 1 | 4 | 4.5 | 114.3 | 0.438 | 11.13 | 19 | 28.32 |

| 2 | 5 | 5.563 | 141.3 | 0.5 | 12.7 | 27.04 | 40.28 |

| 3 | 6 | 6.625 | 168.3 | 0.562 | 14.27 | 36.39 | 54.2 |

| 4 | 8 | 8.625 | 219.1 | 0.719 | 18.26 | 60.71 | 90.44 |

| 5 | 10 | 10.75 | 273 | 0.844 | 21.44 | 89.29 | 133.06 |

| 6 | 12 | 12.75 | 323.8 | 1 | 25.4 | 125.49 | 186.97 |

| 7 | 14 | 14 | 355.6 | 1.094 | 27.79 | 150.79 | 224.65 |

| 8 | 16 | 16 | 406.4 | 1.219 | 30.96 | 192.43 | 286.64 |

| 9 | 18 | 18 | 457 | 1.375 | 34.93 | 244.14 | 363.56 |

| 10 | 20 | 20 | 508 | 1.5 | 38.1 | 296.37 | 441.49 |

| 11 | 22 | 22 | 559 | 1.625 | 41.28 | 353.61 | 527.02 |

| 12 | 24 | 24 | 610 | 1.812 | 46.02 | 429.39 | 640.03 |

| wdt_ID | Nom. Size (in) | OD (in) | OD (mm) | Wall Thkns (in) | Wall Thkns (mm) | Wgt (lb/ft) | Wgt (kg/m) |

|---|---|---|---|---|---|---|---|

| 1 | 4 | 4.5 | 114.3 | 0.438 | 11.13 | 19 | 28.32 |

| 2 | 5 | 5.563 | 141.3 | 0.5 | 12.7 | 27.04 | 40.28 |

| 3 | 6 | 6.625 | 168.3 | 0.562 | 14.27 | 36.39 | 54.2 |

| 4 | 8 | 8.625 | 219.1 | 0.719 | 18.26 | 60.71 | 90.44 |

| 5 | 10 | 10.75 | 273 | 0.844 | 21.44 | 89.29 | 133.06 |

| 6 | 12 | 12.75 | 323.8 | 1 | 25.4 | 125.49 | 186.97 |

| 7 | 14 | 14 | 355.6 | 1.094 | 27.79 | 150.79 | 224.65 |

| 8 | 16 | 16 | 406.4 | 1.219 | 30.96 | 192.43 | 286.64 |

| 9 | 18 | 18 | 457 | 1.375 | 34.93 | 244.14 | 363.56 |

| 10 | 20 | 20 | 508 | 1.5 | 38.1 | 296.37 | 441.49 |

| 11 | 22 | 22 | 559 | 1.625 | 41.28 | 353.61 | 527.02 |

| 12 | 24 | 24 | 610 | 1.812 | 46.02 | 429.39 | 640.03 |

Dimensional Values

The Thickness, Weight Dimension Table for Line Pipe Schedule 120 constitutes the dimensional values (in columns) for each nominal size (inches) in rows.

The nominal size (inches) refers to the non-approximate size for the purpose of description or trade. In piping, it’s called the nominal pipe size that is equal to the inside diameter (ID).

An increase in wall size decreases the inside diameter.

The outside diameter (inches) is the pipe measurement from left to right or top to bottom that originates from the pipe’s outer wall.

Outside Diameter = Circumference / pi (3.1415)Wall thickness (inches and millimeters) is specified by the term schedule. The wall thickness is the measurement (inches) of the pipe’s wall.

Wall Thickness = Inside Diameter – Outside Diameter / 2

Weight refers to the pipe’s weight measured in pounds per feet or kilograms per meter. Here is the formula to calculate it:

A copper tube, for instance, has a formula of (Outer Diameter – Wall Thickness) x thickness (mm) x -0.02796 x length (m).

Line Pipe Schedule 120 Dimension, Weight and Thickness Chart Abbreviations:

- OD – Outside Diameter

- in – inches

- mm – millimeter

- lb/ft – pounds per feet

- kg/m – kilogram per meter

- Wgt – Weight

- Nom. Size – Nominal Size

- Wall Thkns – Wall Thickness

Leveraging High-Pressure Schedule 120 Line Pipe for Critical Pipeline Applications

When designing pipeline systems for extreme pressure environments or critical infrastructure, Schedule 120 line pipe provides the exceptional wall thickness and structural integrity required for the most demanding oilfield applications. The Line Pipe Schedule 120 Dimension, Weight and Thickness Chart offers essential reference data that helps engineers and procurement specialists select the appropriate heavy-duty pipe specifications based on specific high-pressure requirements, safety factors, and operational parameters. At FlowTech Energy, we maintain an inventory of Schedule 120 line pipe across various diameters to support specialized projects requiring maximum pressure handling capabilities and enhanced mechanical protection.

Our technical experts understand that proper schedule selection is crucial for ensuring operational safety and reliability in high-pressure pipeline systems. Schedule 120 pipe is particularly valuable for critical service applications, high-pressure transmission lines, and situations where maximum mechanical strength is essential, such as sour service environments or areas with external mechanical stress. Contact us today at 1-877-645-6693 to discuss how our inventory of quality Schedule 120 line pipe can provide the robust solution your high-pressure pipeline project demands. Whether you’re designing new high-pressure infrastructure or upgrading existing systems to handle increased operating pressures, our selection of API-compliant Schedule 120 line pipe ensures you’ll find the exact specifications needed to maximize both safety margins and operational reliability throughout your pipeline system’s lifecycle.

Go here if you are looking for the Line Pipe Schedule 100 Dimension, Weight and Thickness Chart.