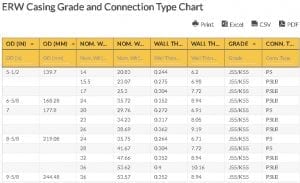

ERW Casing Grade and Connection Type Chart

The Electric Resistance Welding (ERW) casing and connection presents with one longitudinal weld seam without application of filler steel. The production of ERW casing starts out as skelp, a long and coiled steel ribbon.

The Electric Resistance Welding (ERW) casing and connection presents with one longitudinal weld seam without application of filler steel. The production of ERW casing starts out as skelp, a long and coiled steel ribbon.

Initially, the skelp is cut according to the required length, resulting in a flat rectangular sheet, which will then be fed into a rolling machine. This will mechanically press the edges of the skelp together, after which it is longitudinally welded across its length using electric-resistance or electric-induction welding. A minimum heat treatment of 1000oF is applied to the ERW casing weld seam afterward to ensure the absence of untempered martensite remains.

Electrical Resistance Welding (ERW) Casing and Connection Qualities

An Electrical Resistance Welding (ERW) Casing can be produced with a minimum outer diameter of 2 3/8 inches and a maximum of 24 inches, with a welded joint on its cross-section.

The ERW steel casing comes in various lengths, with some reaching over 100 feet, and the surface finish may either be in bare or coated forms.

ERW casing and connection is recommended for low to medium pressure operations, including water or oil transportation.

Electrical Resistance Welding (ERW) Casing and Connection Advantages

The biggest advantage of the ERW steel casing is its manufacturing process. Using electrical resistance welding allows the full length of the casing to remain clean, since only the casing edges are heated and welded together. The weld seam of the steel casing made from ERW is the only part that needs cleaning or trimming, reducing the work involved in the post-weld cleaning process.

Another plus point for the ERW steel casing is the ease of its installation along constricted areas. This is secondary to having a standardized casing dimension because changes occur only at the welded seam, leaving a clean, flat seam that runs the complete length of the casing.

Other benefits of the ERW casing and connection include being more cost effective and readily available, as well as the possibility of checking the steel’s internal surface prior to manufacture.

ERW Casing Grade and Connection Type Chart

| OD (in) | OD (mm) | Nom. Wt (lb/ft) | Nom. Wt (kg/m) | Wall Thkns (in) | Wall Thkns (mm) | Grade | Conn. Type | |

|---|---|---|---|---|---|---|---|---|

| wdt_ID | OD (in) | OD (mm) | Nom. Wt (lb/ft) | Nom. Wt (kg/m) | Wall Thkns (in) | Wall Thkns (mm) | Grade | Conn. Type |

| 1 | 5-1/2 | 139.7 | 14 | 20.83 | 0.244 | 6.2 | J55/K55 | PS |

| 2 | 15.5 | 23.07 | 0.275 | 6.98 | J55/K55 | PSLB | ||

| 3 | 17 | 25.3 | 0.304 | 7.72 | J55/K55 | PSLB | ||

| 4 | 6-5/8 | 168.28 | 24 | 35.72 | 0.352 | 8.94 | J55/K55 | PSLB |

| 5 | 7 | 177.8 | 20 | 29.76 | 0.272 | 6.91 | J55/K55 | PS |

| 6 | 23 | 34.23 | 0.317 | 8.05 | J55/K55 | PSLB | ||

| 7 | 26 | 38.69 | 0.362 | 9.19 | J55/K55 | PSLB | ||

| 8 | 8-5/8 | 219.08 | 24 | 35.75 | 0.264 | 6.71 | J55/K55 | PS |

| 9 | 28 | 41.67 | 0.304 | 7.72 | J55/K55 | PS | ||

| 10 | 32 | 47.66 | 0.352 | 8.94 | J55/K55 | PSLB | ||

| 11 | 36 | 53.62 | 0.4 | 10.16 | J55/K55 | PSLB | ||

| 12 | 9-5/8 | 244.48 | 36 | 53.57 | 0.352 | 8.94 | J55/K55 | PSLB |

| 13 | 40 | 59.53 | 0.395 | 10.03 | J55/K55 | PSLB | ||

| 14 | 10-3/4 | 273.05 | 40.5 | 60.32 | 0.35 | 8.89 | J55/K55 | PSB |

| 15 | 45.5 | 67.78 | 0.4 | 10.16 | J55/K55 | PSB | ||

| 16 | 13-3/8 | 339.7 | 48 | 71.43 | 0.33 | 8.38 | J55/K55 | PSB |

| 17 | 54.5 | 81.18 | 0.38 | 9.65 | J55/K55 | PSB | ||

| 18 | 61 | 90.86 | 0.43 | 10.92 | J55/K55 | PSB | ||

| 19 | 68 | 101.29 | 0.48 | 12.19 | J55/K55 | PSB |

ERW Casing Grade and Connection Type Chart

| OD (in) | OD (mm) | Nom. Wt (lb/ft) | Nom. Wt (kg/m) | Wall Thkns (in) | Wall Thkns (mm) | Grade | Conn. Type | |

|---|---|---|---|---|---|---|---|---|

| wdt_ID | OD (in) | OD (mm) | Nom. Wt (lb/ft) | Nom. Wt (kg/m) | Wall Thkns (in) | Wall Thkns (mm) | Grade | Conn. Type |

| 1 | 5-1/2 | 139.7 | 14 | 20.83 | 0.244 | 6.2 | J55/K55 | PS |

| 2 | 15.5 | 23.07 | 0.275 | 6.98 | J55/K55 | PSLB | ||

| 3 | 17 | 25.3 | 0.304 | 7.72 | J55/K55 | PSLB | ||

| 4 | 6-5/8 | 168.28 | 24 | 35.72 | 0.352 | 8.94 | J55/K55 | PSLB |

| 5 | 7 | 177.8 | 20 | 29.76 | 0.272 | 6.91 | J55/K55 | PS |

| 6 | 23 | 34.23 | 0.317 | 8.05 | J55/K55 | PSLB | ||

| 7 | 26 | 38.69 | 0.362 | 9.19 | J55/K55 | PSLB | ||

| 8 | 8-5/8 | 219.08 | 24 | 35.75 | 0.264 | 6.71 | J55/K55 | PS |

| 9 | 28 | 41.67 | 0.304 | 7.72 | J55/K55 | PS | ||

| 10 | 32 | 47.66 | 0.352 | 8.94 | J55/K55 | PSLB | ||

| 11 | 36 | 53.62 | 0.4 | 10.16 | J55/K55 | PSLB | ||

| 12 | 9-5/8 | 244.48 | 36 | 53.57 | 0.352 | 8.94 | J55/K55 | PSLB |

| 13 | 40 | 59.53 | 0.395 | 10.03 | J55/K55 | PSLB | ||

| 14 | 10-3/4 | 273.05 | 40.5 | 60.32 | 0.35 | 8.89 | J55/K55 | PSB |

| 15 | 45.5 | 67.78 | 0.4 | 10.16 | J55/K55 | PSB | ||

| 16 | 13-3/8 | 339.7 | 48 | 71.43 | 0.33 | 8.38 | J55/K55 | PSB |

| 17 | 54.5 | 81.18 | 0.38 | 9.65 | J55/K55 | PSB | ||

| 18 | 61 | 90.86 | 0.43 | 10.92 | J55/K55 | PSB | ||

| 19 | 68 | 101.29 | 0.48 | 12.19 | J55/K55 | PSB |

Electrical Resistance Welding (ERW) Casing and Connection Abbreviations:

in. – inches

mm – millimeters

lb/ft. – pounds per feet

kg/m – kilogram per meter

Oil and gas well operators take many standards into consideration when choosing the right casing for their operations. Being able to select the appropriate steel casing will eventually allow them to save time and money.

Electrical Resistance Welding (ERW) Casing and Connection Terms:

The specifications for ERW steel casing and other types of casing are usually expressed in outer diameter (in or mm), nominal weight (lb/ft or kg/m), wall thickness (in or mm), and grade and connection type.

Outer Diameter

Casings are specified by the outer diameter and are usually fixed for a particular size.

Nominal Weight

This shows the average linear weight of the ERW casing and connection.

Wall Thickness

The mechanical strength of the ERW casing depends on its wall thickness.

Grade

The ERW steel casing’s strength and material composition are reflected by the grade of the casing.

Connection Type

The type of thread used to connect the ERW steel casing’s joints is shown on the connection type. Premium connections are described as follows:

- P – plain end

- S – short round thread

- B – buttress

- L – long round thread

Go here if you are looking for the Seamless Casing Grade and Connection Type Chart.