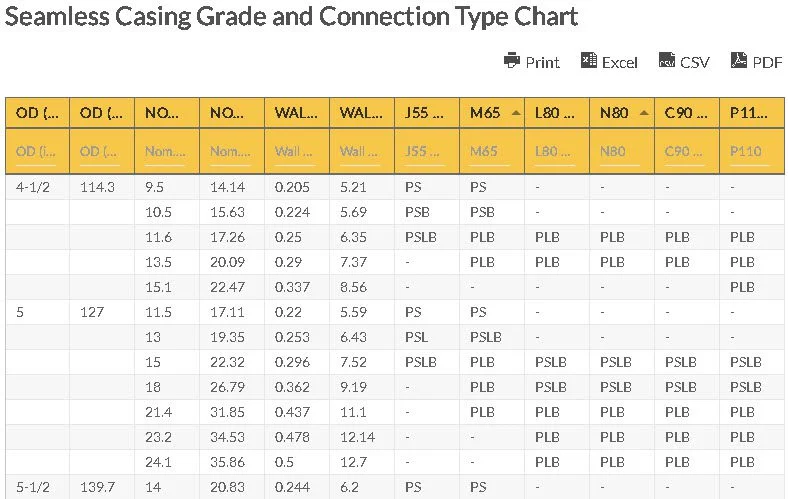

Seamless Casing Grade and Connection Type Chart

Seamless casing and connection is considered the most commonly utilized oil-field casing today. Seamless casing is produced in a pipe mill using a billet, a solid cylindrical piece of steel. The manufacturing process takes place through the exposure of the billet to high temperature; billet penetration using a mandrel; passage of the billet into the rollers and internal mandrels to size it up; treatment of the tube with heat; and straightening and final sizing.

Seamless Casing and Connection Features

The dimensional and wall thickness specifications of oil well seamless casing ranges from 1/8 inch to 26 inches OD. It is particularly suited for high-pressure operations, including oil and gas exploration and drilling, hydrocarbon industries and refineries, and oil and gas transportation. The threading of the connections of the seamless casing may be done either by the manufacturer or by other companies. Ensuring the uniformity of the seamless casing wall thickness is a challenge to manufacturers. The production process may cause slight eccentricity to the cross section of the seamless casing wall.

Seamless Casing and Connection over Welded Type

Seamless casing and connection presents advantages over the welded type. The primary advantage of the seamless casing foroil well is the absence of a weld seam, which is considered a weak spot that can pose risks of failure and corrosion. In addition, better roundness is seen with seamless casing and connection. Lastly, the possibility of having a weak seam is omitted.The only weak points associated with seamless casing and connection for oil wells are the disparities in wall thickness, challenges in the production process, and the higher costs.

Seamless Casing Grade and Connection Type Chart

| wdt_ID | OD (in) | OD (mm) | Nom. Wt (lb/ft) | Nom. Wt (kg/m) | Wall Thkns (in) | Wall Thkns (mm) | J55 K55 | M65 | L80 C95 | N80 | C90 T95 | P110 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 4-1/2 | 114.3 | 9.5 | 14.14 | 0.205 | 5.21 | PS | PS | - | - | - | - |

| 2 | 10.5 | 15.63 | 0.224 | 5.69 | PSB | PSB | - | - | - | - | ||

| 3 | 11.6 | 17.26 | 0.25 | 6.35 | PSLB | PLB | PLB | PLB | PLB | PLB | ||

| 4 | 13.5 | 20.09 | 0.29 | 7.37 | - | PLB | PLB | PLB | PLB | PLB | ||

| 5 | 15.1 | 22.47 | 0.337 | 8.56 | - | - | - | - | - | PLB | ||

| 6 | 5 | 127 | 11.5 | 17.11 | 0.22 | 5.59 | PS | PS | - | - | - | - |

| 7 | 13 | 19.35 | 0.253 | 6.43 | PSL | PSLB | - | - | - | - | ||

| 8 | 15 | 22.32 | 0.296 | 7.52 | PSLB | PLB | PSLB | PSLB | PSLB | PSLB | ||

| 9 | 18 | 26.79 | 0.362 | 9.19 | - | PLB | PSLB | PSLB | PSLB | PSLB | ||

| 10 | 21.4 | 31.85 | 0.437 | 11.1 | - | PLB | PLB | PLB | PLB | PLB | ||

| 11 | 23.2 | 34.53 | 0.478 | 12.14 | - | - | PLB | PLB | PLB | PLB | ||

| 12 | 24.1 | 35.86 | 0.5 | 12.7 | - | - | PLB | PLB | PLB | PLB | ||

| 13 | 5-1/2 | 139.7 | 14 | 20.83 | 0.244 | 6.2 | PS | PS | - | - | - | - |

| 14 | 15.5 | 23.07 | 0.275 | 6.98 | PSLB | PSLB | - | - | - | - | ||

| 15 | 17 | 25.3 | 0.304 | 7.72 | PSLB | PLB | PSLB | PSLB | PLB | PSLB | ||

| 16 | 20 | 29.76 | 0.361 | 9.17 | - | PLB | PSLB | PSLB | PLB | PSLB | ||

| 17 | 23 | 34.23 | 0.415 | 10.54 | - | PLB | PSLB | PSLB | PLB | PSLB | ||

| 18 | 6-5/8 | 168.28 | 20 | 29.76 | 0.288 | 7.32 | PSLB | PSLB | - | - | - | - |

| 19 | 24 | 35.72 | 0.352 | 8.94 | PSLB | PLB | PSLB | PSLB | PSLB | PSLB | ||

| 20 | 28 | 41.67 | 0.417 | 10.59 | - | PLB | PSLB | PSLB | PSLB | PSLB | ||

| 21 | 32 | 47.62 | 0.475 | 12.06 | - | - | PSLB | PSLB | PSLB | PSLB | ||

| 22 | 7 | 177.8 | 20 | 29.76 | 0.272 | 6.91 | PS | PS | - | - | - | - |

| 23 | 23 | 34.23 | 0.317 | 8.05 | PSLB | PLB | PSLB | PSLB | PLB | - | ||

| 24 | 26 | 38.69 | 0.362 | 9.19 | PSLB | PLB | PSLB | PSLB | PLB | PSLB | ||

| 25 | 29 | 43.16 | 0.408 | 10.36 | - | PLB | PSLB | PSLB | PLB | PSLB | ||

| 26 | 32 | 47.62 | 0.453 | 11.51 | - | PLB | PSLB | PSLB | PLB | PSLB | ||

| 27 | 35 | 52.13 | 0.498 | 12.65 | - | - | PSLB | PSLB | PLB | PSLB | ||

| 28 | 38 | 56.6 | 0.54 | 13.72 | - | - | PSLB | PSLB | PLB | PSLB | ||

| 29 | 7-5/8 | 193.68 | 26.4 | 39.29 | 0.328 | 8.33 | PSLB | PSLB | PLB | PLB | PLB | - |

| 30 | 29.7 | 44.2 | 0.375 | 9.52 | - | PLB | PLB | PLB | PLB | PLB | ||

| 31 | 33.7 | 50.15 | 0.43 | 10.92 | - | PLB | PLB | PLB | PLB | PLB | ||

| 32 | 39 | 58.05 | 0.5 | 12.7 | - | - | PLB | PLB | PLB | PLB | ||

| 33 | 42.8 | 63.69 | 0.562 | 14.27 | - | - | PLB | PLB | PLB | PLB | ||

| 34 | 45.3 | 67.41 | 0.595 | 15.11 | - | - | PLB | PLB | PLB | PLB | ||

| 35 | 47.1 | 70.09 | 0.625 | 15.88 | - | - | PLB | PLB | PLB | PLB | ||

| 36 | 8-5/8 | 219.08 | 24 | 36.75 | 0.264 | 6.71 | PS | PS | - | - | - | - |

| 37 | 28 | 41.67 | 0.304 | 7.72 | - | PS | - | - | - | - | ||

| 38 | 32 | 47.66 | 0.352 | 8.94 | PSLB | PSLB | - | - | - | - | ||

| 39 | 36 | 53.62 | 0.4 | 10.16 | PSLB | PSLB | PLB | PLB | PLB | - | ||

| 40 | 40 | 59.58 | 0.45 | 11.43 | - | PLB | PLB | PLB | PLB | PLB | ||

| 41 | 44 | 65.54 | 0.5 | 12.7 | - | - | PLB | PLB | PLB | PLB | ||

| 42 | 49 | 72.99 | 0.557 | 14.15 | - | - | PLB | PLB | PLB | PLB | ||

| 43 | 9-5/8 | 244.48 | 36 | 53.57 | 0.352 | 8.94 | PSLB | PSLB | - | - | - | - |

| 44 | 40 | 59.53 | 0.395 | 10.03 | PSLB | PSLB | PLB | PLB | PLB | - | ||

| 45 | 43.5 | 64.73 | 0.435 | 11.05 | - | PLB | PLB | PLB | PLB | PLB | ||

| 46 | 47 | 69.94 | 0.472 | 11.99 | - | PLB | PLB | PLB | PLB | PLB | ||

| 47 | 53.5 | 79.62 | 0.545 | 13.84 | - | - | PLB | PLB | PLB | PLB | ||

| 48 | 58.4 | 86.91 | 0.595 | 15.11 | - | - | PLB | PLB | PLB | PLB | ||

| 49 | 10-3/4 | 273.05 | 40.5 | 60.32 | 0.35 | 8.89 | PSB | PSB | PLB | PLB | PLB | PLB |

| 50 | 45.5 | 67.78 | 0.4 | 10.16 | PSB | PSB | - | - | - | - | ||

| 51 | 51 | 75.96 | 0.45 | 11.43 | PSB | PSB | PSB | PSB | PSB | PSB | ||

| 52 | 55.5 | 72.67 | 0.495 | 12.57 | - | PSB | PSB | PSB | PSB | PSB | ||

| 53 | 60.7 | 90.41 | 0.545 | 13.84 | - | - | - | - | PSB | PSB | ||

| 54 | 65.7 | 97.86 | 0.595 | 15.11 | - | - | - | - | PSB | PSB | ||

| 55 | 13-3/8 | 339.7 | 54.5 | 81.18 | 0.38 | 9.65 | PSB | PSB | - | - | PSB | PSB |

| 56 | 61 | 90.86 | 0.43 | 10.92 | PSB | PSB | - | - | - | - | ||

| 57 | 68 | 101.29 | 0.48 | 12.19 | PSB | PSB | PSB | PSB | PSB | PSB | ||

| 58 | 72 | 107.24 | 0.514 | 13.06 | - | - | - | - | PSB | PSB | ||

| 59 | 20 | 508 | 94 | 139.89 | 0.438 | 11.13 | SLB | SLB | - | - | - | - |

| 60 | 106.5 | 158.49 | 0.5 | 12.7 | SLB | SLB | - | - | - | - | ||

| 61 | 133 | 197.93 | 0.635 | 16.13 | SLB | - | - | - | - | - |

| wdt_ID | OD (in) | OD (mm) | Nom. Wt (lb/ft) | Nom. Wt (kg/m) | Wall Thkns (in) | Wall Thkns (mm) | J55 K55 | M65 | L80 C95 | N80 | C90 T95 | P110 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 4-1/2 | 114.3 | 9.5 | 14.14 | 0.205 | 5.21 | PS | PS | - | - | - | - |

| 2 | 10.5 | 15.63 | 0.224 | 5.69 | PSB | PSB | - | - | - | - | ||

| 3 | 11.6 | 17.26 | 0.25 | 6.35 | PSLB | PLB | PLB | PLB | PLB | PLB | ||

| 4 | 13.5 | 20.09 | 0.29 | 7.37 | - | PLB | PLB | PLB | PLB | PLB | ||

| 5 | 15.1 | 22.47 | 0.337 | 8.56 | - | - | - | - | - | PLB | ||

| 6 | 5 | 127 | 11.5 | 17.11 | 0.22 | 5.59 | PS | PS | - | - | - | - |

| 7 | 13 | 19.35 | 0.253 | 6.43 | PSL | PSLB | - | - | - | - | ||

| 8 | 15 | 22.32 | 0.296 | 7.52 | PSLB | PLB | PSLB | PSLB | PSLB | PSLB | ||

| 9 | 18 | 26.79 | 0.362 | 9.19 | - | PLB | PSLB | PSLB | PSLB | PSLB | ||

| 10 | 21.4 | 31.85 | 0.437 | 11.1 | - | PLB | PLB | PLB | PLB | PLB | ||

| 11 | 23.2 | 34.53 | 0.478 | 12.14 | - | - | PLB | PLB | PLB | PLB | ||

| 12 | 24.1 | 35.86 | 0.5 | 12.7 | - | - | PLB | PLB | PLB | PLB | ||

| 13 | 5-1/2 | 139.7 | 14 | 20.83 | 0.244 | 6.2 | PS | PS | - | - | - | - |

| 14 | 15.5 | 23.07 | 0.275 | 6.98 | PSLB | PSLB | - | - | - | - | ||

| 15 | 17 | 25.3 | 0.304 | 7.72 | PSLB | PLB | PSLB | PSLB | PLB | PSLB | ||

| 16 | 20 | 29.76 | 0.361 | 9.17 | - | PLB | PSLB | PSLB | PLB | PSLB | ||

| 17 | 23 | 34.23 | 0.415 | 10.54 | - | PLB | PSLB | PSLB | PLB | PSLB | ||

| 18 | 6-5/8 | 168.28 | 20 | 29.76 | 0.288 | 7.32 | PSLB | PSLB | - | - | - | - |

| 19 | 24 | 35.72 | 0.352 | 8.94 | PSLB | PLB | PSLB | PSLB | PSLB | PSLB | ||

| 20 | 28 | 41.67 | 0.417 | 10.59 | - | PLB | PSLB | PSLB | PSLB | PSLB | ||

| 21 | 32 | 47.62 | 0.475 | 12.06 | - | - | PSLB | PSLB | PSLB | PSLB | ||

| 22 | 7 | 177.8 | 20 | 29.76 | 0.272 | 6.91 | PS | PS | - | - | - | - |

| 23 | 23 | 34.23 | 0.317 | 8.05 | PSLB | PLB | PSLB | PSLB | PLB | - | ||

| 24 | 26 | 38.69 | 0.362 | 9.19 | PSLB | PLB | PSLB | PSLB | PLB | PSLB | ||

| 25 | 29 | 43.16 | 0.408 | 10.36 | - | PLB | PSLB | PSLB | PLB | PSLB | ||

| 26 | 32 | 47.62 | 0.453 | 11.51 | - | PLB | PSLB | PSLB | PLB | PSLB | ||

| 27 | 35 | 52.13 | 0.498 | 12.65 | - | - | PSLB | PSLB | PLB | PSLB | ||

| 28 | 38 | 56.6 | 0.54 | 13.72 | - | - | PSLB | PSLB | PLB | PSLB | ||

| 29 | 7-5/8 | 193.68 | 26.4 | 39.29 | 0.328 | 8.33 | PSLB | PSLB | PLB | PLB | PLB | - |

| 30 | 29.7 | 44.2 | 0.375 | 9.52 | - | PLB | PLB | PLB | PLB | PLB | ||

| 31 | 33.7 | 50.15 | 0.43 | 10.92 | - | PLB | PLB | PLB | PLB | PLB | ||

| 32 | 39 | 58.05 | 0.5 | 12.7 | - | - | PLB | PLB | PLB | PLB | ||

| 33 | 42.8 | 63.69 | 0.562 | 14.27 | - | - | PLB | PLB | PLB | PLB | ||

| 34 | 45.3 | 67.41 | 0.595 | 15.11 | - | - | PLB | PLB | PLB | PLB | ||

| 35 | 47.1 | 70.09 | 0.625 | 15.88 | - | - | PLB | PLB | PLB | PLB | ||

| 36 | 8-5/8 | 219.08 | 24 | 36.75 | 0.264 | 6.71 | PS | PS | - | - | - | - |

| 37 | 28 | 41.67 | 0.304 | 7.72 | - | PS | - | - | - | - | ||

| 38 | 32 | 47.66 | 0.352 | 8.94 | PSLB | PSLB | - | - | - | - | ||

| 39 | 36 | 53.62 | 0.4 | 10.16 | PSLB | PSLB | PLB | PLB | PLB | - | ||

| 40 | 40 | 59.58 | 0.45 | 11.43 | - | PLB | PLB | PLB | PLB | PLB | ||

| 41 | 44 | 65.54 | 0.5 | 12.7 | - | - | PLB | PLB | PLB | PLB | ||

| 42 | 49 | 72.99 | 0.557 | 14.15 | - | - | PLB | PLB | PLB | PLB | ||

| 43 | 9-5/8 | 244.48 | 36 | 53.57 | 0.352 | 8.94 | PSLB | PSLB | - | - | - | - |

| 44 | 40 | 59.53 | 0.395 | 10.03 | PSLB | PSLB | PLB | PLB | PLB | - | ||

| 45 | 43.5 | 64.73 | 0.435 | 11.05 | - | PLB | PLB | PLB | PLB | PLB | ||

| 46 | 47 | 69.94 | 0.472 | 11.99 | - | PLB | PLB | PLB | PLB | PLB | ||

| 47 | 53.5 | 79.62 | 0.545 | 13.84 | - | - | PLB | PLB | PLB | PLB | ||

| 48 | 58.4 | 86.91 | 0.595 | 15.11 | - | - | PLB | PLB | PLB | PLB | ||

| 49 | 10-3/4 | 273.05 | 40.5 | 60.32 | 0.35 | 8.89 | PSB | PSB | PLB | PLB | PLB | PLB |

| 50 | 45.5 | 67.78 | 0.4 | 10.16 | PSB | PSB | - | - | - | - | ||

| 51 | 51 | 75.96 | 0.45 | 11.43 | PSB | PSB | PSB | PSB | PSB | PSB | ||

| 52 | 55.5 | 72.67 | 0.495 | 12.57 | - | PSB | PSB | PSB | PSB | PSB | ||

| 53 | 60.7 | 90.41 | 0.545 | 13.84 | - | - | - | - | PSB | PSB | ||

| 54 | 65.7 | 97.86 | 0.595 | 15.11 | - | - | - | - | PSB | PSB | ||

| 55 | 13-3/8 | 339.7 | 54.5 | 81.18 | 0.38 | 9.65 | PSB | PSB | - | - | PSB | PSB |

| 56 | 61 | 90.86 | 0.43 | 10.92 | PSB | PSB | - | - | - | - | ||

| 57 | 68 | 101.29 | 0.48 | 12.19 | PSB | PSB | PSB | PSB | PSB | PSB | ||

| 58 | 72 | 107.24 | 0.514 | 13.06 | - | - | - | - | PSB | PSB | ||

| 59 | 20 | 508 | 94 | 139.89 | 0.438 | 11.13 | SLB | SLB | - | - | - | - |

| 60 | 106.5 | 158.49 | 0.5 | 12.7 | SLB | SLB | - | - | - | - | ||

| 61 | 133 | 197.93 | 0.635 | 16.13 | SLB | - | - | - | - | - |

Seamless Casing Grade and Connection Type Chart Abbreviations:

- in. – Inches

- mm – millimeter

- lb/ft – pounds per feet

- kg/m – kilogram per meter

- P – Plain Ends

- S – Short round thread

- L – Long round thread

- B – Buttress thread

Casing Specification:

In utilizing seamless casing and connection, the purchaser and designer should follow the standards set by the American Petroleum Institute (API). The organization provides a variety of manufacturing standards for tubing and casing, which are also adopted by the International Standards Organization (ISO).Casing specifications are usually presented in outer diameter (in or mm), nominal weight (lb/ft or kg/m), wall thickness (in or mm), and grade and connection type.

- Outer Diameter: Outer diameter is usually fixed for a particular size.

- Nominal Weight: The nominal weight presented in lb/ft or kg/m portrays the average linear weight of the seamless casing and connection, which limits the casing wall thickness that in turn defines the inner diameter.

- Grade: The yield strength and material composition of the seamless casingare indicated by the grade of the casing.

- Connection Type: The connection type shows the type of thread used to affix the oil well seamless casing joints.

Premium connections can be defined as

- P – plain end

- S – short round thread

- B – buttress

- L – long round thread

Specifying Seamless Casing for Critical Well Applications

Seamless casing represents the premium standard for demanding drilling environments where weld seam integrity cannot be compromised, including high-pressure high-temperature (HPHT) wells, sour gas service with H2S exposure, deep exploratory drilling, and critical production wells with extended service life requirements. The chart above provides comprehensive specifications for seamless casing grades and connection types, enabling drilling engineers and procurement teams to select the optimal combination of material strength, collapse resistance, and connection performance for challenging downhole conditions. While seamless casing typically commands a price premium over ERW alternatives, the elimination of longitudinal weld seams provides superior structural integrity, more uniform stress distribution under extreme loads, and enhanced corrosion resistance in aggressive wellbore environments. Understanding the full range of seamless casing grades—from standard H40 through premium grades like L80, P110, and Q125—ensures you’re matching material properties to the specific pressure, temperature, and chemical exposure conditions encountered in your wells.

Flowtech Energy stocks API 5CT certified seamless casing in sizes ranging from 4-1/2 inch through 13-3/8 inch, covering the most common casing strings used in oil and gas drilling operations worldwide. Our inventory includes various connection types from basic short round thread to premium buttress and proprietary gas-tight connections designed for the most demanding applications. Each seamless casing section is supplied with mill test reports (MTRs) documenting chemical composition, mechanical properties, and hydrostatic test results to ensure full compliance with API specifications and operator requirements. We also maintain select inventory of premium used seamless casing that has been inspected, tested, and certified for redeployment—offering cost-effective alternatives for operators seeking seamless quality at reduced capital expenditure. If you need assistance selecting the appropriate seamless casing grade for corrosive environments, evaluating connection options for high-torque directional drilling, or sourcing specific sizes and weights for your drilling program, contact Flowtech Energy at 1-877-645-6693. Our technical team provides expert guidance on casing selection, complete material documentation, and worldwide logistics support—ensuring your critical wells are constructed with seamless casing that delivers reliable performance and long-term integrity.

Go here if you are looking for the API Casing Specification Chart.