Used Premium Drill Pipe Torsion, Tensile and Pressure Data Chart

Used premium drill pipe torsion, tensile, and pressure data can be helpful in determining the limitations of a certain pipe. This will become a guide on what type of pipe to use in certain situations.

For premium pipe, a higher torsion, pressure, and tensile strength implies that it would have less chances of breakage, affecting its efficiency and longevity due to tension and other factors.

Used Premium Drill Pipe Torsion, Tensile, and Pressure Discussion

Torsion, pressure, and tensile strength are important factors to consider in installing pipe. It is relevant to know these terms further.

Torsional strength refers to the capability of a material to resist loads that cause the pipe to twist. This is the maximum strength and torsional stress a material is subjected to during torsional loading. It is also termed as shear or rupture strength. The calculation of the strength depends on whether the pipe is solid or hollow.

Tensile strength relates to the pipe’s elasticity. It refers to the material’s strength to withstand pulling force without any damage.

Pressure strength is the ability of a material to withstand force that reduces a pipe’s size.

Torsion, Tensile, and Pressure Strength Formula

In a study of the pipe’s strength, these three factors are analyzed and calculated independently.

Torsional Strength:

T= HP x 5250/RPM

T= torque delivered to DP, ft-lb

HP = the horse power exerted to make the pipe rotate

RPM = revolution per minute

Tensile Strength

lb. = psi x in2

lb = tensile strength

psi = minimum yield strength

in2 = cross sectional area

Pressure Strength:

P = (2*S*T)/((O.D.-2*T)*SF)

P = fluid pressure

T = pipe wall thickness

S = material strength

O.D. = pipe outside diameter

SF = safety factor

Used Premium Drill Pipe Torsion, Tensile and Pressure Benefits

The Premium Class pipe has been used globally and has become a norm in the industry for drilling compared to Class 2. This is due to the significant difference in the minimum tool joint outside diameter, maximum allowable slip out, and tube wall thickness.

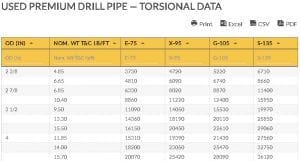

USED PREMIUM DRILL PIPE — TORSIONAL DATA

| OD (in) | Nom. Wt T&C lb/ft | E-75 | X-95 | G-105 | S-135 | |

|---|---|---|---|---|---|---|

| wdt_ID | OD (in) | Nom. Wt T&C lb/ft | E-75 | X-95 | G-105 | S-135 |

| 1 | 2 3/8 | 4.85 | 3730 | 4720 | 5220 | 6710 |

| 2 | 6.65 | 4810 | 6090 | 6740 | 8660 | |

| 3 | 2 7/8 | 6.85 | 6330 | 8020 | 8870 | 11400 |

| 4 | 10.40 | 8860 | 11220 | 12400 | 15950 | |

| 5 | 3 1/2 | 9.50 | 11090 | 14050 | 15530 | 19970 |

| 6 | 13.30 | 14360 | 18190 | 20110 | 25850 | |

| 7 | 15.50 | 16150 | 20450 | 22610 | 29060 | |

| 8 | 4 | 11.85 | 15310 | 19390 | 21430 | 27560 |

| 9 | 14.00 | 18200 | 23050 | 25470 | 32750 | |

| 10 | 15.70 | 20070 | 25420 | 28090 | 36120 |

USED PREMIUM DRILL PIPE — TORSIONAL DATA

| OD (in) | Nom. Wt T&C lb/ft | E-75 | X-95 | G-105 | S-135 | |

|---|---|---|---|---|---|---|

| wdt_ID | OD (in) | Nom. Wt T&C lb/ft | E-75 | X-95 | G-105 | S-135 |

| 1 | 2 3/8 | 4.85 | 3730 | 4720 | 5220 | 6710 |

| 2 | 6.65 | 4810 | 6090 | 6740 | 8660 | |

| 3 | 2 7/8 | 6.85 | 6330 | 8020 | 8870 | 11400 |

| 4 | 10.40 | 8860 | 11220 | 12400 | 15950 | |

| 5 | 3 1/2 | 9.50 | 11090 | 14050 | 15530 | 19970 |

| 6 | 13.30 | 14360 | 18190 | 20110 | 25850 | |

| 7 | 15.50 | 16150 | 20450 | 22610 | 29060 | |

| 8 | 4 | 11.85 | 15310 | 19390 | 21430 | 27560 |

| 9 | 14.00 | 18200 | 23050 | 25470 | 32750 | |

| 10 | 15.70 | 20070 | 25420 | 28090 | 36120 |

USED PREMIUM DRILL PIPE — TENSILE DATA

| OD (in) | Nom. Wt T&C lb/ft | E-75 | X-95 | G-105 | S-135 | |

|---|---|---|---|---|---|---|

| wdt_ID | OD (in) | Nom. Wt T&C lb/ft | E-75 | X-95 | G-105 | S-135 |

| 1 | 2 3/8 | 4.85 | 76890 | 97400 | 107650 | 138410 |

| 2 | 6.65 | 107620 | 136310 | 150660 | 193710 | |

| 3 | 2 7/8 | 6.85 | 106950 | 135470 | 149730 | 192500 |

| 4 | 10.40 | 166540 | 210950 | 233150 | 299760 | |

| 5 | 3 1/2 | 9.50 | 152980 | 193770 | 214170 | 275360 |

| 6 | 13.30 | 212150 | 268720 | 297010 | 381870 | |

| 7 | 15.50 | 250620 | 317450 | 350870 | 451120 | |

| 8 | 4 | 11.85 | 182020 | 230550 | 254820 | 327630 |

| 9 | 14.00 | 224180 | 283960 | 313850 | 403530 | |

| 10 | 15.70 | 253850 | 321540 | 355390 | 456930 |

USED PREMIUM DRILL PIPE — TENSILE DATA

| OD (in) | Nom. Wt T&C lb/ft | E-75 | X-95 | G-105 | S-135 | |

|---|---|---|---|---|---|---|

| wdt_ID | OD (in) | Nom. Wt T&C lb/ft | E-75 | X-95 | G-105 | S-135 |

| 1 | 2 3/8 | 4.85 | 76890 | 97400 | 107650 | 138410 |

| 2 | 6.65 | 107620 | 136310 | 150660 | 193710 | |

| 3 | 2 7/8 | 6.85 | 106950 | 135470 | 149730 | 192500 |

| 4 | 10.40 | 166540 | 210950 | 233150 | 299760 | |

| 5 | 3 1/2 | 9.50 | 152980 | 193770 | 214170 | 275360 |

| 6 | 13.30 | 212150 | 268720 | 297010 | 381870 | |

| 7 | 15.50 | 250620 | 317450 | 350870 | 451120 | |

| 8 | 4 | 11.85 | 182020 | 230550 | 254820 | 327630 |

| 9 | 14.00 | 224180 | 283960 | 313850 | 403530 | |

| 10 | 15.70 | 253850 | 321540 | 355390 | 456930 |

USED PREMIUM DRILL PIPE — COLLAPSE PRESSURE DATA

| OD (in) | Nom. Wt T&C lb/ft | E-75 | X-95 | G-105 | S-135 | |

|---|---|---|---|---|---|---|

| wdt_ID | OD (in) | Nom. Wt T&C lb/ft | E-75 | X-95 | G-105 | S-135 |

| 1 | 2 3/8 | 4.85 | 8520 | 10160 | 10910 | 12890 |

| 2 | 6.65 | 13380 | 16950 | 18730 | 24080 | |

| 3 | 2 7/8 | 6.85 | 7640 | 9020 | 9630 | 11190 |

| 4 | 10.40 | 14220 | 18020 | 19910 | 25600 | |

| 5 | 3 1/2 | 9.50 | 7070 | 8280 | 8810 | 10090 |

| 6 | 13.30 | 12020 | 15220 | 16820 | 21630 | |

| 7 | 15.50 | 14470 | 18330 | 20260 | 26050 | |

| 8 | 4 | 11.85 | 5700 | 6510 | 6830 | 7450 |

| 9 | 14.00 | 9010 | 10800 | 11620 | 13840 | |

| 10 | 15.70 | 10910 | 13830 | 15190 | 18590 |

USED PREMIUM DRILL PIPE — COLLAPSE PRESSURE DATA

| OD (in) | Nom. Wt T&C lb/ft | E-75 | X-95 | G-105 | S-135 | |

|---|---|---|---|---|---|---|

| wdt_ID | OD (in) | Nom. Wt T&C lb/ft | E-75 | X-95 | G-105 | S-135 |

| 1 | 2 3/8 | 4.85 | 8520 | 10160 | 10910 | 12890 |

| 2 | 6.65 | 13380 | 16950 | 18730 | 24080 | |

| 3 | 2 7/8 | 6.85 | 7640 | 9020 | 9630 | 11190 |

| 4 | 10.40 | 14220 | 18020 | 19910 | 25600 | |

| 5 | 3 1/2 | 9.50 | 7070 | 8280 | 8810 | 10090 |

| 6 | 13.30 | 12020 | 15220 | 16820 | 21630 | |

| 7 | 15.50 | 14470 | 18330 | 20260 | 26050 | |

| 8 | 4 | 11.85 | 5700 | 6510 | 6830 | 7450 |

| 9 | 14.00 | 9010 | 10800 | 11620 | 13840 | |

| 10 | 15.70 | 10910 | 13830 | 15190 | 18590 |

USED PREMIUM DRILL PIPE — INTERNAL PRESSURE DATA

| OD (in) | Nom. Wt T&C lb/ft | E-75 | X-95 | G-105 | S-135 | |

|---|---|---|---|---|---|---|

| wdt_ID | OD (in) | Nom. Wt T&C lb/ft | E-75 | X-95 | G-105 | S-135 |

| 1 | 2 3/8 | 4.85 | 9600 | 12160 | 13440 | 17280 |

| 2 | 6.65 | 14150 | 17920 | 19810 | 25470 | |

| 3 | 2 7/8 | 6.85 | 9060 | 11470 | 12680 | 16300 |

| 4 | 10.40 | 15110 | 19140 | 21150 | 27200 | |

| 5 | 3 1/2 | 9.50 | 8710 | 11030 | 12190 | 15680 |

| 6 | 13.30 | 12520 | 15980 | 17660 | 22710 | |

| 7 | 15.50 | 15390 | 19500 | 21550 | 27710 | |

| 8 | 4 | 11.85 | 7860 | 9960 | 11000 | 14150 |

| 9 | 14.00 | 9900 | 12540 | 13860 | 17820 | |

| 10 | 15.70 | 11400 | 14440 | 15960 | 20520 |

USED PREMIUM DRILL PIPE — INTERNAL PRESSURE DATA

| OD (in) | Nom. Wt T&C lb/ft | E-75 | X-95 | G-105 | S-135 | |

|---|---|---|---|---|---|---|

| wdt_ID | OD (in) | Nom. Wt T&C lb/ft | E-75 | X-95 | G-105 | S-135 |

| 1 | 2 3/8 | 4.85 | 9600 | 12160 | 13440 | 17280 |

| 2 | 6.65 | 14150 | 17920 | 19810 | 25470 | |

| 3 | 2 7/8 | 6.85 | 9060 | 11470 | 12680 | 16300 |

| 4 | 10.40 | 15110 | 19140 | 21150 | 27200 | |

| 5 | 3 1/2 | 9.50 | 8710 | 11030 | 12190 | 15680 |

| 6 | 13.30 | 12520 | 15980 | 17660 | 22710 | |

| 7 | 15.50 | 15390 | 19500 | 21550 | 27710 | |

| 8 | 4 | 11.85 | 7860 | 9960 | 11000 | 14150 |

| 9 | 14.00 | 9900 | 12540 | 13860 | 17820 | |

| 10 | 15.70 | 11400 | 14440 | 15960 | 20520 |

Used Premium Drill Pipe Torsion, Tensile and Pressure Data Chart Abbreviations:

OD – Outer Diameter

T & C – Threaded and coupled ends

in – inches

lb/ft – pounds per feet

ft-lb – foot-pounds

lb – pounds

psi – pounds per square inch

Metric System:

O.D X 25.4 = mm

I.D x 25.4 = mm Wall x 25.4 = mm

Go here if you are looking for the New Drill Pipe Torsion, Tensile and Pressure Data Chart.