Caprock Pumping Unit Features

Caprock Pumping Unit – The Caprock Gear Box features a combination of a ductile iron housing and forged high tensile cast steel gearing to produce a gear box that is superior to the common cast and steel combination.

- Ductile Iron Case Houses component gears with a split center line for easy disassembly

- Double Helical Gears Heat Treated Steel Gear Teeth exceed API specs for pitting & bending stresses

- Center Relief for positive relief flow to all gear tooth interfaces and a submerged gear & wiper system

- Alloy Steel Shafts Rotating in oversized precision roller bearings. No bronze bushing to seize and no shaft to wear out

The Caprock Pumping Unit bearing assemblies feature machined ductile iron casting with over sized double row self aligning roller bearings and large lubricant reservoir..

The Caprock Pumping Unit horsehead is fitted with steel casting to provide totally safe lockouts during inclement weather and regular maintenance. The horsehead is easily removed and attached for well servicing.

The Caprock Pumping Unit brake has a positive stop locking pawl for totally safe lockouts during inclement weather and regular maintenance

The Caprock Pumping Unit counterbalance weights and crank arms have integral t slots and graduate markings for fast and easy installation and positioning of counter weights. The cast Rack and Pinion locks the weights in place.

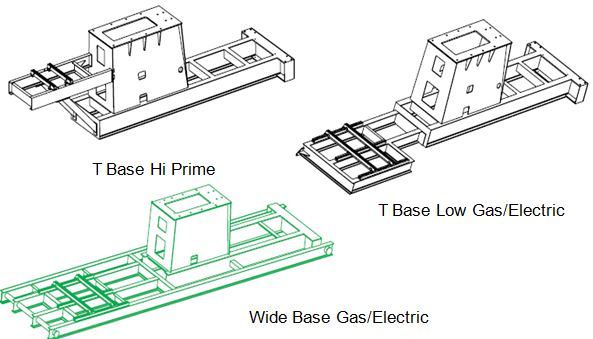

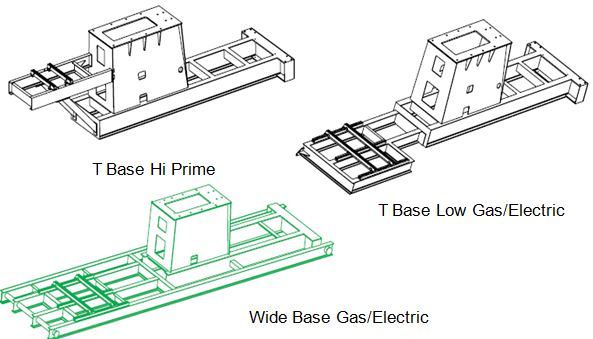

All CAPROCK Pumping Units have multiple base configurations available to fit all customer application requirements:

- T-Base High Prime for electric power source applications

- Wide Base Low Prime for gas/electric power source applications

- T-Base Low Prime for gas/electric power source applications

We also Offer Hercules Pumpjack unit.