What is Vertical Multistage Centrifugal Pump?

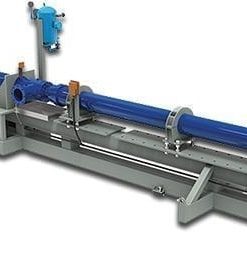

Vertical multistage centrifugal pumps have a vertical shaft, where stages are stacked one on top of the next.

Advantages of a vertical centrifugal pump design:

- It is suitable for spaces where the ground surface area is restricted.

- It requires a smaller footprint than that of horizontal pumps

- With a vertical centrifugal pump, the NPSH available can be increased.

- Such pumps are suitable for higher temperature and high pressure fluids.

Vertical multistage centrifugal pumps are great for areas that don’t have much footprint to spare. Its ability to deliver high pressure output with a single pump body and motor combo is also a plus.

It is important to keep in mind, however, that this type of pump does not tolerate debris or significant solids, and is also vulnerable to deadhead conditions.

Multistage pumps provide many key benefits, from energy savings, to ability to operate in a wide range of flow/head scenarios. If you think it might be right for your application, be sure to discuss with a qualified engineer first. They’ll make sure the right pump is selected specifically for your purpose.

Vertical multistage centrifugal pumps are ideal for water, light weight fluids and highly forceful watery liquids. Due to its valuable features and specifications, vertical Multistage Pumps are used in variety of applications such as fire fighting, water treatment plants, food processing, irrigation, domestic water supply, sprinkling etc.

The higher flow output impellers help in transferring the fluid using the mechanical energy and ensure to satisfy the needs of users. The range of models with nominal capacities is available. Vertical multistage centrifugal pumps are highly reliable, efficient, space saving and give highly positive performance for slightly aggressive liquids.

Vertical multistage centrifugal pumps are reliable & service friendly, Space saving, suitable for slightly aggressive liquids Energy efficient.

Applications of Vertical Multistage Centrifugal Pumps:

- Water supply of boilers & condensate system

- Cooling & air-conditioning system

- Water treatment, reverse osmosis system

- Industrial cleaning system

- Municipal water supply & boosting

- Pressure boosting for high rise buildings

Vertical centrifugal pumps are also referred to as cantilever pumps. They utilize a unique shaft andbearing support configuration that allows the volute to hang in the sump while the bearings are outside of the sump. This style of pump uses no stuffing box to seal the shaft but instead utilizes a “throttle Bushing”. A common application for this style of pump is in a parts washer.