Multi Stage Centrifugal Pumps

Multi stage centrifugal pumps have multiple liquid chambers (or stages) that are connected in series. Fluid enters the first chamber at suction line pressure and leaves at some elevated pressure. Upon leaving the first stage, the fluid enters the second stage where the pressure is increased further.

The more stages the pump has, the higher the final discharge pressure. Multi stage centrifugal pumps have the unique ability to produce higher and higher pressures with the addition of every stage, but flow range always remains constant for a given rpm.

Multi stage centrifugal pumps are now primarily used in this severe service. Two typical styles of multi stage centrifugal pumps barrel and horizontally split pumps are offered by different manufacturers.

There are a couple different types of multi stage pumps. Those with a horizontal shaft, and those with a vertical shaft.

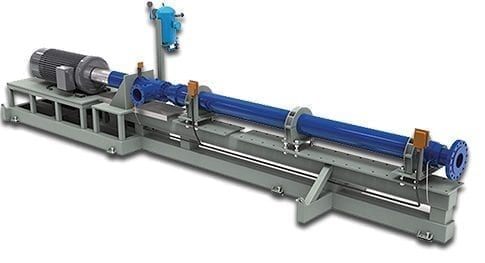

Horizontal Multistage Centrifugal Pumps:

This type of pump has a segmented casing with modular interstage components. The rotating assembly is held between bearing housings, making the assembly more balanced for high pressures.

They typically handle higher flow rates than vertical multistage pumps (with the exception of vertical turbine pumps).

The horizontal configuration of multistage pumps is best applied in applications like these:

- Reverse Osmosis

- Boiler Feed

- Shower

- Spray

- Cogeneration

- Mine dewatering

- Condensate

- Pressure Boosting

- High Pressure Cleaning

- Snow making

This type of pump is pretty maintenance intensive, however. It takes a high skill set to work on these horizontal centrifungal pumps and ensure they are put back together properly. They can also be quite costly upfront, depending on the degree of specification required and the materials of construction.

Vertical Multistage Centrifugal Pumps:

Vertical multistage centrifugal pumps have a vertical shaft, where stages are stacked one on top of the next.

High pressure shower systems

Boiler feedwater

Desuperheater feed

Vertical multistage pumps are great for areas that don’t have much footprint to spare. Its ability to deliver high pressure output with a single pump body and motor combo is also a plus.

It is important to keep in mind, however, that this type of pump does not tolerate debris or significant solids, and is also vulnerable to deadhead conditions.

Multistage pumps provide many key benefits, from energy savings, to ability to operate in a wide range of flow/head scenarios. If you think it might be right for your application, be sure to discuss with a qualified engineer first. They’ll make sure the right pump is selected specifically for your purpose.

Multi Stage Centrifugal pumps Applications:

- Water disposal/injection

- Crude Oil transfer

- Fluid transfer of most liquids