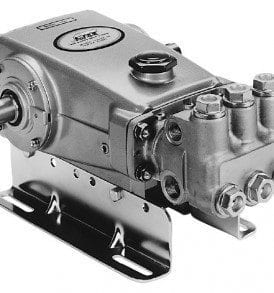

15 Frame Plunger Pump – Special concentric, high density, polished, solid ceramic plungers provide a true wear surface and extended seal life. Manifolds are a high tensile strength bronze for long term, continuous duty and corrosion resistance. 100% wet seal design of plunger pump adds to service life by allowing pumped liquids to cool and lubricate on both sides. Stainless steel valves, seats and springs provide corrosion-resistance, ultimate seating and extended life. Specially formulated, Cat Pump exclusive, V Packing offer unmatched performance and seal life.

Plunger Pump Features:

- Stacked valve design of plunger pump for ease in servicing.

- Pre set Lo Pressure Seals provide secondary protection against external leaks and require no packing adjustment.

- Triplex design offers high efficiency and low pulsation.

- Durable V Packings are lubricated and cooled by the liquid being pumped.

- Optional STHT and FPM elastomers for compatibility with many liquids and temperatures up to 200°F

- Special high-density, polished, concentric plungers provide a true wear surface and extended seal life.

Plunger Pump Quality Materials:

- Chrome-moly crankshaft gives unmatched strength and surface hardness.

- All stainless steel valves are heat treated and seats are roller burnished for a positive seal and extended valve life.

- Bronze or Duplex Stainless Steel manifolds are strong and corrosion resistance.

- Oversized crankshaft bearings with greater loading capacity mean longer bearing life.

- Special concentric, high-density, polished, solid ceramic plungers provide atrue wear surface and extended seal life.

- Specially formulated, CAT PUMP exclusive, V-Packings offer unmatched performance and seal life.

- Die cast aluminum crankcase provides high strength, minimum weight and precision tolerance control.

Plunger Pump Easy Maintenance:

- Inlet and discharge valve assemblies interchange for easier maintenance without disturbing piping.

- Wet-end is easily serviced without entering crankcase, requiring less time and effort.

- Preset packings mean no packing gland adjustment is necessary, reducing maintenance costs.

PLUNGER PUMP SPECIFICATIONS

| Standard | Metric | |||

| Flow | 7.0 gpm | 27 lpm | ||

| Pressure Range | 100 to 3000 psi | 7 to 210 bar | ||

| RPM | 1000 rpm | 1000 rpm | ||

| Inlet Pressure Range | –5 to +60 psi | –0.35 to +4 bar | ||

| Bore | .787″ | 20 mm | ||

| Stroke | 1.181″ | 30 mm | ||

| Crankcase Capacity | 42 oz. | 1.26 l | ||

| Maximum Liquid Temperature | 160°F | 71°C | ||

| Above 130F call Cat Pumps for inlet conditions and elastomer recommendations. | ||||

| Inlet Ports (2) | 3/4″ NPTF | 3/4″ NPTF | ||

| Discharge Ports (2) | 1/2″ NPTF | 1/2″ NPTF | ||

| Pulley Mounting | Either Side | Either Side | ||

| Shaft Diameter | 1.181″ | 30 mm | ||

| Weight | 44 lbs. | 19.9 kg | ||

| Dimensions | 16.28×12.99×6.44″ | 413.50x330x163.50 mm | ||