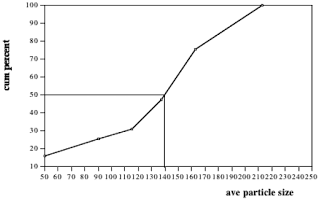

One of the considerable disadvantages in using garnet and other similar minerals as a cutting agent in abrasive waterjet cutting is that the particles fragment during the mixing process, and when they hit the target. As a result (as noted in the last post) less than 50% and often much less than that can be […]

Tag Archives: abrasive

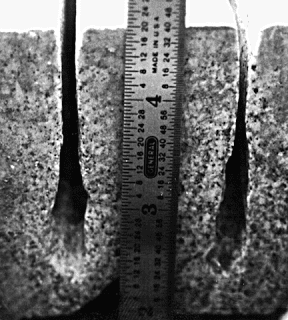

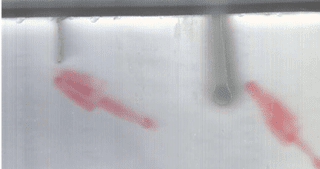

In the last post I wrote about the impact of smaller jet diameters, and higher pressures, in truncating the range over which a waterjet is effective. The same is true, to an extent, when one adds abrasive to the water. Our “green tube” test has been described in earlier posts, where the distance over which […]

In an early section of these notes on high-pressure water and its uses, there was a review of some of the ways in which jet power could be assessed. For the most part the best way to see how changes in a system alter the way the jets cut is to run a simple cutting […]

When the Direct Injection of Abrasive jet (DIAjet) was first introduced to the general public, back in 1986, there was some initial skepticism as to the overall market potential for the system. Certainly, as the next post will discuss, the ability to transfer higher levels of energy from the pressurized water to the entrained abrasive […]

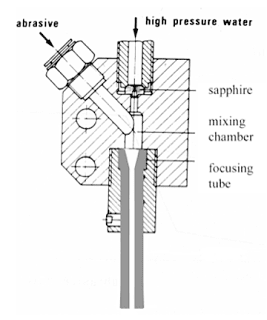

In an earlier part of this series I wrote about the introduction of abrasive into waterjets, and the loss in energy that occurs when the abrasive and the air that transports it are accelerated into the waterjet stream in the mixing chamber of a conventional abrasive waterjet nozzle assembly. Figure 1. Conventional mixing of abrasive […]