This is just a short video from back in the days when 1/2-inch tapes were still our way of recording, but before we reached the higher quality resolution of today. We had a problem in that the basement of our building was partially covered with dirt, and concrete window wells held that back from the […]

Tag Archives: Cutting

The video that I posted last time did not fare as well as had been hoped, in making the trip from my computer to the blogger post, and so this week, to see if there are other ways of peeling the apple, I have also posted a copy of the video to Youtube, to see […]

There are several different aspects to be considered when planning a job entailing hole cutting, the accuracy needed for the hole(s) to be cut, both in shape and alignment, the quality of the wall and the speed of the operation. Not all are important in each case. But they are combined through the amount of […]

Frontal photographs taken of waterjets, regardless of pressure, show that the jet spray widens as the jet moves away from the nozzle. Yet, because of the erosion of the outer layers of the jet by the surrounding fluid, the central core of effective jet pressure reduces as that distance grows. The normal way in which […]

In the recent past I have written about the use of polymers in high-pressure jets and that they can significantly improve jetting performance, with no additional changes in the power or pump and equipment used in the work. This is because of two different effects that the polymers have. Firstly they reduce turbulence in the […]

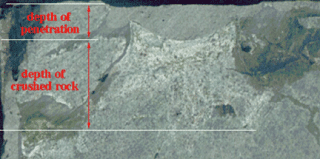

In previous posts I have written about the use of lower pressure water (around 10,000 psi) as a way of cutting through rock. From the time that we first made a hole through nine-inches of granite while I was a graduate student some 50-odd years ago the way that we have recommended that rock be […]

Safety glass, or toughened glass is typically designed so that, when it fails it will break into small pieces with few of the relatively sharp, and thus dangerous, fragments formed by ordinary glass. It is used in making shower doors, and automobile windows. As such is differs from laminated glass (which I will discuss in […]

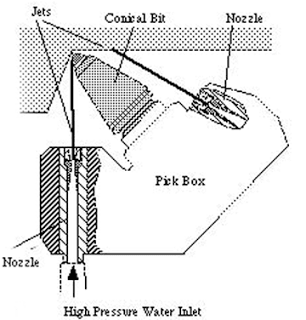

In the earlier posts in this chapter I have discussed the problem of getting the nozzle of a waterjet system close enough to the tool:target contact that the jet retains enough power to be effective. At the same time the jet must strike within roughly 1/10th of an inch of that contact to be effective […]

In the earlier posts in this chapter I have discussed the problem of getting the nozzle of a waterjet system close enough to the tool:target contact that the jet retains enough power to be effective. At the same time the jet must strike within roughly 1/10th of an inch of that contact to be effective […]

When it was first discovered that high-pressure waterjets could significantly improve the performance of mechanical cutting tools, whether in machining metal, or in cutting rock, it was anticipated that this would have a broad-ranging application. This has not been the case, and the reasons are varied, depending on the application, but quite often they relate […]

The addition of a high-pressure waterjet to the leading edge of a sharp tool can make a considerable difference to the performance of that tool. I have discussed this a little in two earlier posts, the first of which was an introduction to the topic, and the second highlighted the problems of getting the nozzle […]

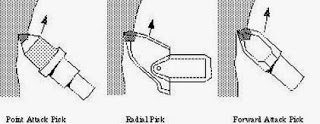

When mankind first began cutting out flints to make the tools and weapons that helped make primitive life more successful they often used either bone antlers or stones from the river as the tool to cut into the chalk or other host rock that held the flint. For thousands of years as rock was excavated […]

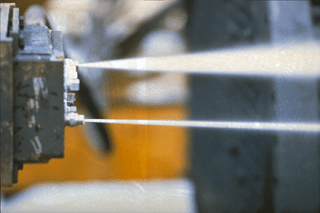

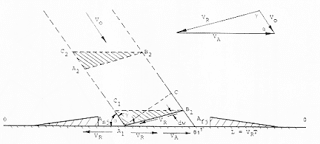

At the end of the last post I mentioned the benefits that could occur if two jets were directed to intersect at a distance from the nozzle. Marian Mazurkiewicz did a lot of early work on this, and it was written up in an ASTM STP.* Because it has a couple of applications that include […]

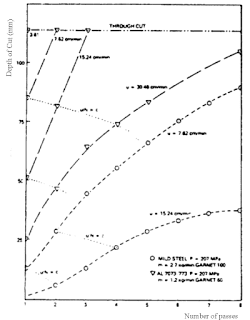

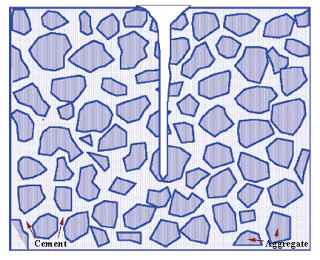

In this short section of the series I have been discussing some of the issues that relate to cutting through concrete. In today’s piece the discussion will continue, focusing on the angles that the jets are set at, when making repeated passes over an area to deepen the cut. The basic premise of the discussion […]

The control of cut depth is one of the more difficult aspects of using high pressure waterjets in places where the aim is not to cut all the way through a part. The ability of an abrasive jet to continue cutting beyond the expected target depth can first be evident to an operator when they […]

- 1

- 2