We began looking into the use of water jets to deal with energetic materials (a group that includes, but is not limited to, explosives) at the beginning of the 1980’s. One of the earliest questions dealt with the need to find the jet pressures at which the explosive materials would react to the impact of […]

Tag Archives: Waterjetting

One of the major efforts carried out at the High Pressure Waterjet Lab at Missouri S&T during my tenure related to removing explosives and other energetic materials from different casings. The casings ranged in size from very small anti-personnel mines to the large rocket motors that carry objects into space. The first part of that […]

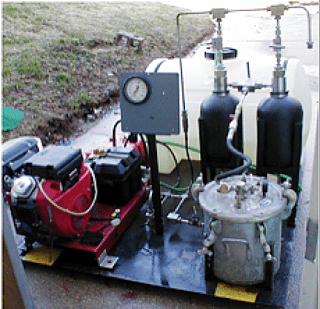

This is a short post illustrating an early stage in our development of a light-weight tool that could be carried into building rubble, after a collapse, and drill down through it to provide access for tools to search, without the danders of destabilizing the pile. We illustrated the lack of vibration by placing a full […]

This is just a short video from back in the days when 1/2-inch tapes were still our way of recording, but before we reached the higher quality resolution of today. We had a problem in that the basement of our building was partially covered with dirt, and concrete window wells held that back from the […]

When I began to write these posts, I wrote about the difference between overall jet force and the focussed effects of a very high-pressure but small diameter jet. At the time I made reference to the relatively low pressure, but huge flow rate effects when Katrina hit New Orleans. I specifically wrote about the damage […]

Stripping tires to recover the rubber has been one of the topics that has come up on a number of occasions, and through a number of different tests we have been able to demonstrate that water jets can remove the material in a range of sizes depending on the desired output. The work has ranged […]

Posting will run just a little slow for a few weeks, as I run-through and catalogue the some 200 hours of video that I have amassed over the decades showing our waterjet research. There are a number of different review reports that I will insert over the next few weeks, as I find the good […]

In the evolution of the design of a waterjet/suction tool described in the last post I commented on the ability to balance the jets so that they did not spray material beyond the suction shroud. At the same time the shroud, to be most effective, has to be within a quarter–of-an-inch of the final surface, […]

The short videotapes in this segment show the evolution of a combination of a waterjet and a suction line as a way of easily removing soil or sand relatively quickly. It is a subject covered in an earlier post. These video clips show some of the tests that helped us to develop that design. As […]

The video that I posted last time did not fare as well as had been hoped, in making the trip from my computer to the blogger post, and so this week, to see if there are other ways of peeling the apple, I have also posted a copy of the video to Youtube, to see […]

This post is by way of an introduction to an occasional new feature of the site, where I will videos to different posts to help with understanding. Adding videos is not in my skill set, so this first is just a general overview of some of the ways in which waterjets have evolved over the […]

When I began writing about hole cutting and drilling, a month ago, I was intending to talk just about the relative efficiencies of cutting the core into larger pieces, rather than designing a cutting pattern that would completely cover the surface of the excavation, milling and removing the core in fine particles. Other topics intruded, […]

In the earlier posts in this section I have concentrated more on cutting the profiles of a hole, and the different ways in which this can be done efficiently. However there are many cases where the hole has to travel into the work piece to a depth greater than can be easily achieved without the […]

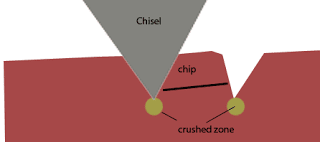

If you ever go to an Old-Time Miners celebration, you may watch a group of competitors drilling holes through rock by hand with a cold chisel and a hammer. (You can see an example here). In the competition the contestant has 5 minutes to drill either a ¾” or 1-inch diameter hole as deep as […]

There are several different aspects to be considered when planning a job entailing hole cutting, the accuracy needed for the hole(s) to be cut, both in shape and alignment, the quality of the wall and the speed of the operation. Not all are important in each case. But they are combined through the amount of […]