Looking back over the Waterjet Index I realized that while I have addressed different aspects of drilling holes with waterjets in various ways, I haven’t really brought it all together as a focused topic. So, herewith, and in the next few posts, that coalescence. It begins with a bit of a recap. It was clear, […]

Tag Archives: Waterjetting

In the last post I reviewed, in part, Dr. Shunli Xu’s work on oscillating nozzles, and how they can, on occasion, almost double the penetration while also improving surface finish. The problem with that basic technique, however, is that the nozzle is oscillating perpendicular to the direction of the cut, which is fine when the […]

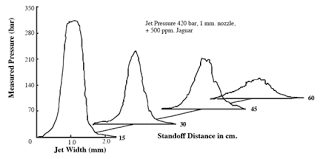

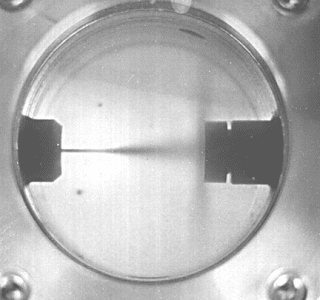

Frontal photographs taken of waterjets, regardless of pressure, show that the jet spray widens as the jet moves away from the nozzle. Yet, because of the erosion of the outer layers of the jet by the surrounding fluid, the central core of effective jet pressure reduces as that distance grows. The normal way in which […]

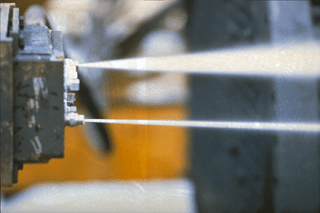

The structure of the jet flow from an orifice makes a tremendous difference to the ability that the jet then has in terms both of its range and its cutting ability. And one of the major factors that control the structure of the jet lies in the flow conditions just upstream of the orifice itself. […]

When a waterjet first comes out of an orifice the flow (providing the upstream conditions are properly aligned) will form a cylindrical stream, with the jet pressure across that stream relatively constant. Within about an inch, depending on the flow conditions, ripples start to appear on that smooth cylinder (Rayleigh waves) and these grow and […]

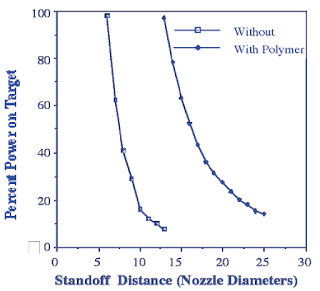

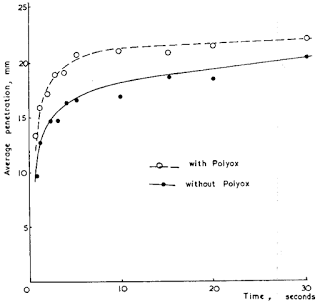

In the recent past I have written about the use of polymers in high-pressure jets and that they can significantly improve jetting performance, with no additional changes in the power or pump and equipment used in the work. This is because of two different effects that the polymers have. Firstly they reduce turbulence in the […]

In the last post on this topic I pointed out that one of early drivers to the use of long-chain polymers in water came from the reduction in friction that it provided to fluid flow through long pipes. In many instances this has been the driving force for the selling of the product, and in […]

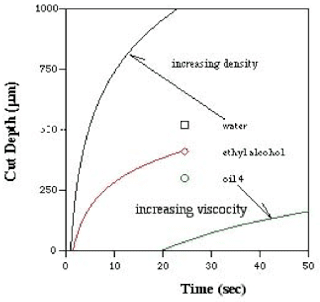

If we lower the viscosity of the fluid in a jet hitting a target, then the jet can penetrate into the fissures and flaws of that surface more easily and in this way it will see an improved cutting performance. On the other hand the thinner fluids have less resistance to the air or other […]

From time to time I am asked why we use water in almost every application of high-pressure waterjet use, rather than using any one of a number of other choices for the fluid. There are a couple of major reasons for this. The first is that most of the uses of the tool will require […]

There is a trick that one can learn while a teenager, which comes with the introduction “I so strong that I can blow a brick over!” Upon finding a suitable victim to impress, the brick is placed over a deflated balloon, which is then inflated, raising the brick which then, if suitably placed, topples onto […]

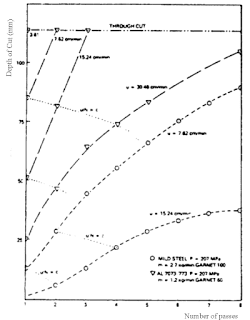

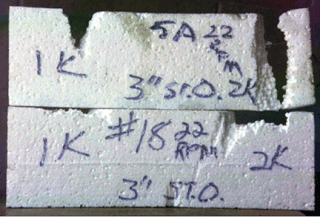

The last post included the idea that, with a jet penetrating to most of its final depth in the first 1/100th of a second, that the best traverse speed that could be used would end up around 50 ft per minute. Actually this is a little low as an estimate, and the reason for this […]

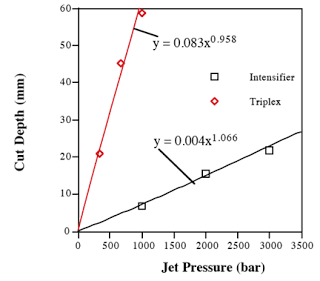

One of the more surprising things that we learned at the beginning of the research into high pressure waterjet action was how quickly a jet will penetrate to almost full depth of penetration, and how slowly it will cut deeper after that. It is a lesson that often escapes even those who work with the […]

A high-pressure waterjet will penetrate into a material by penetrating into small cracks in the surface and pressurizing those cracks, so that they grow and join together freeing material. This mechanism changes where one moves to add abrasive, but that discussion will come later. The larger the cracks in the material, then the lower the […]

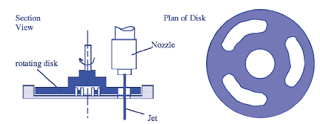

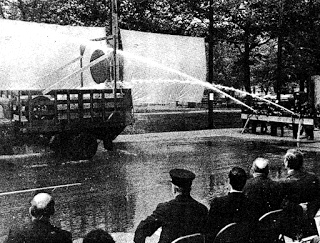

Much of the work that we carry out with high pressure waterjets requires that they cut with precision and, in consequence much of the focus has been on controlling the stream of the jet to obtain the tightly constrained cutting action that produces this result. Yet two of the larger growth sectors of the industry, […]

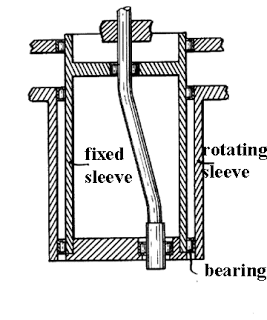

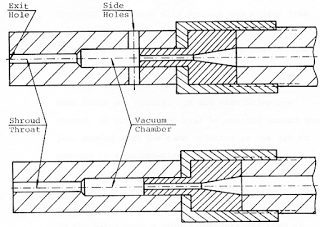

In the last post I wrote about the benefits of cutting a deep slot around the edges of a tunnel, and made reference to the work done here by Dr. El-Saie back in the mid-1970’s as part of his Doctoral Dissertation. One of the concerns that we had to address was that the waterjet had […]