Looking back over the period where we first started coming together to discuss high-pressure water jets, some 40-odd years ago I was reminded of the work of one of my then graduate students (and subsequent faculty member in Egypt) Dr. Ahmed El-Saie. He obtained his doctorate in 1977 and looking back on that work it […]

Tag Archives: Waterjetting

When the International Symposia on Waterjet Cutting (ISJCT) began (back in 1972) the uses of the tool were severely limited, both by the pressures available to customers, and by the limited knowledge of the capabilities of the system. Skip forward four decades and while the various tools available have widely broadened (the maximum pressure we […]

There was a story that is told in Mining Engineering classes about a tunnel that collapsed, even after there had been a whole series of tests carried out to make sure that the rock was strong enough before the tunnel excavation was started. In working out why the tunnel had collapsed some questions were raised […]

In my last post on this topic I wrote about two of the most influential papers that were published in the Proceedings of the First International Symposium on Jet Cutting Technology (hereafter ISJCT) back in 1972. Yet there was one more paper that I remembered over the years. And it has been for an entirely […]

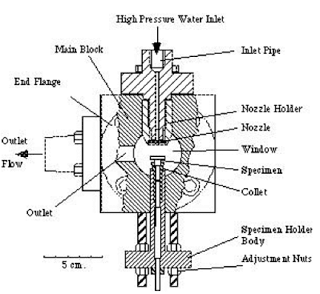

I was saddened, this week, to hear of the passing of Dr. Andrej Lichtarowicz, who died on the the 6th of this month. As Mark Fairhurst noted, Dr. Lichtarowicz, on the faculty at Nottingham University, was a sterling early contributor to the waterjetting community, from its birth back in the early 1970’s. He gave a […]

The great advantage in teaching the same academic course each year for a relatively long period of time was that, after a while, it became easier to look at the contents of each individual lecture, and then adjust the material to fit the changes in what we knew since the lecture had last been given. […]

One of the considerable disadvantages in using garnet and other similar minerals as a cutting agent in abrasive waterjet cutting is that the particles fragment during the mixing process, and when they hit the target. As a result (as noted in the last post) less than 50% and often much less than that can be […]

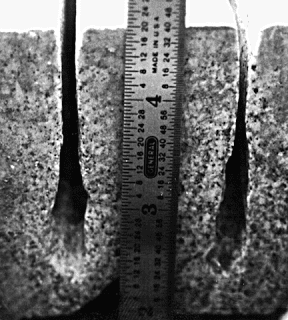

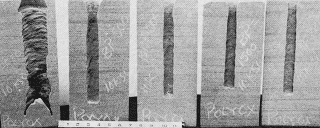

In previous posts I have written about the use of lower pressure water (around 10,000 psi) as a way of cutting through rock. From the time that we first made a hole through nine-inches of granite while I was a graduate student some 50-odd years ago the way that we have recommended that rock be […]

In the earlier posts on this chapter of waterjet technology I have dealt with the changes in cutting performance when a waterjet stream cuts in to material that is either under pressure, or contains internal stresses that may not be obvious at first glance. In this post I will focus, instead, on the changes in […]

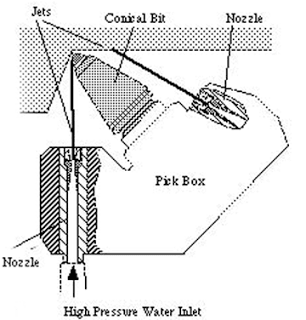

In the last post I described how we initially came up with a simple design for drilling through material, using an axially aligned jet and a larger jet offset to one side at an optimal angle of around 20 degrees. One of the problems with the use of this design is that the outer jet […]

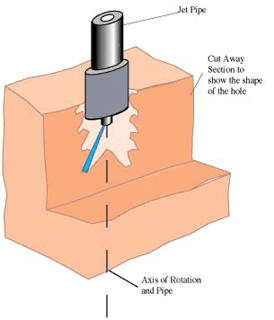

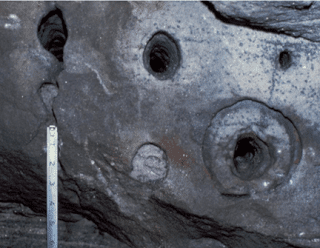

In discussing how stress affects the ability of waterjets to drill rock, I have discussed the effect of the stress in the ground on drill performance, but before discussing the effect of the borehole pressure it is perhaps best to spend this post talking about the simplest drill bit design. The diameter of the first […]

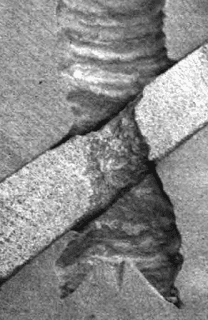

Last time I opened discussion on the topic of cutting a material that contained high levels of stress. This is a more common situation when working with rock, since – as a general rule of thumb – the vertical stress on a rock increases by 1 psi, for every foot deeper one goes into the […]

Safety glass, or toughened glass is typically designed so that, when it fails it will break into small pieces with few of the relatively sharp, and thus dangerous, fragments formed by ordinary glass. It is used in making shower doors, and automobile windows. As such is differs from laminated glass (which I will discuss in […]

In the earlier posts in this chapter I have discussed the problem of getting the nozzle of a waterjet system close enough to the tool:target contact that the jet retains enough power to be effective. At the same time the jet must strike within roughly 1/10th of an inch of that contact to be effective […]

In the earlier posts in this chapter I have discussed the problem of getting the nozzle of a waterjet system close enough to the tool:target contact that the jet retains enough power to be effective. At the same time the jet must strike within roughly 1/10th of an inch of that contact to be effective […]